Assembled type centralized winding stator group

A wire stator group, concentrated winding technology, applied in the direction of windings, electromechanical devices, electric components, etc., can solve the problems that insulating paper is easy to fall and affect assembly, and achieve the effect of improving assembly efficiency and assembly quality, and avoiding falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

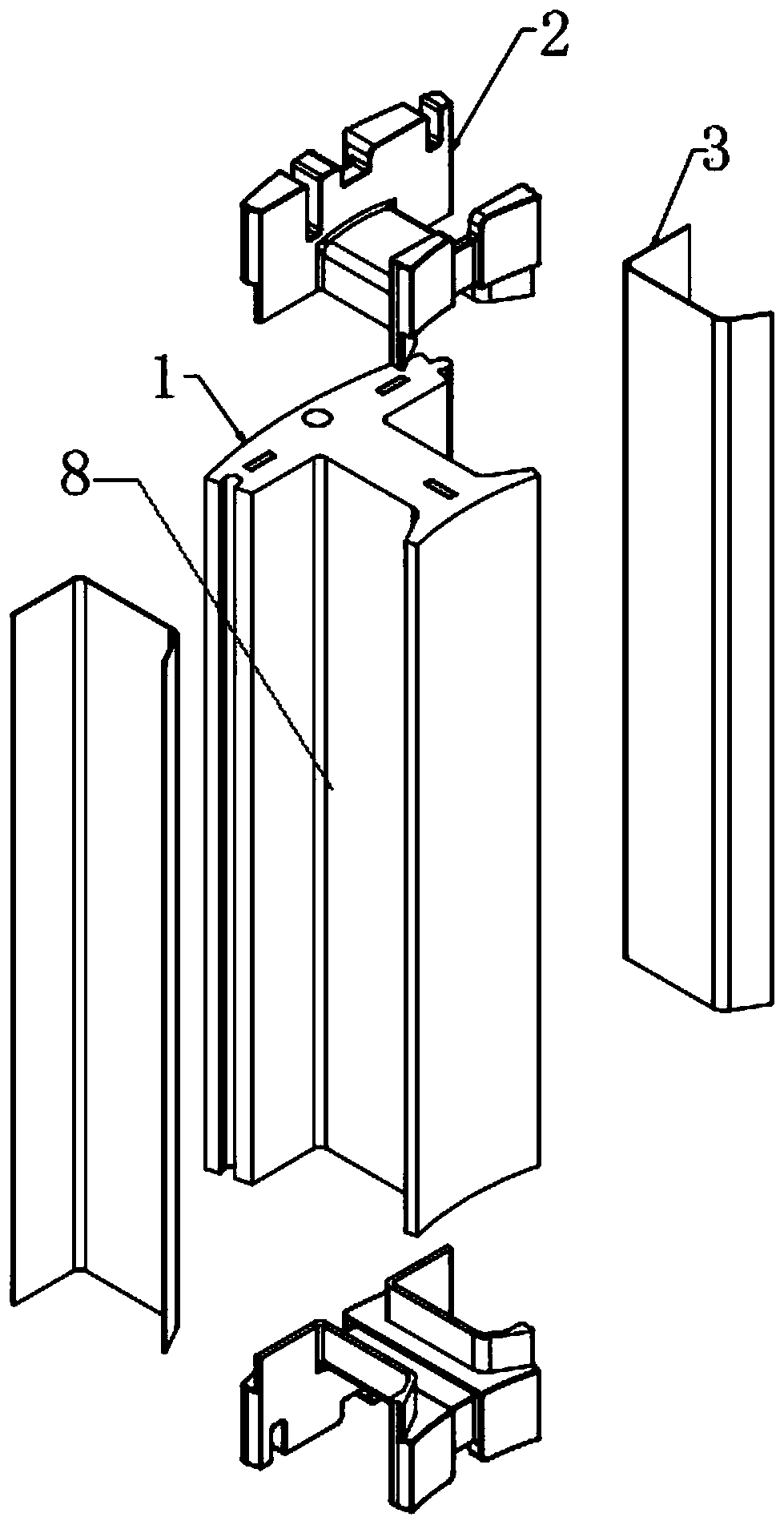

[0029] Such as Figure 1-3 As shown, an assembled centralized winding stator group includes a stator core 1, an insulating film 2 and an insulating paper 3. The stator core 1 is in the shape of a long strip, and the opposite sides of the stator core 1 are sunken inward to form a winding. The slot 8, the insulating film 2 is fixed on both ends of the stator core 1 through the fixing mechanism, and the insulating paper 3 is fixed in the winding slot 8 through the insulating film 2. The insulating paper 3 includes an insulating bottom for covering the bottom of the winding slot 8 and insulating side parts arranged on both sides of the insulating bottom. The fixing mechanism is a buckle 4 arranged along one end of the insulating film 2 along the direction of the stator core 1. The buckle 4 and the insulating film 2 are integrally formed, and the integrally formed structure makes the overall structure more reliable and stable. The buckle 4 is mated and connected with the stator co...

Embodiment 2

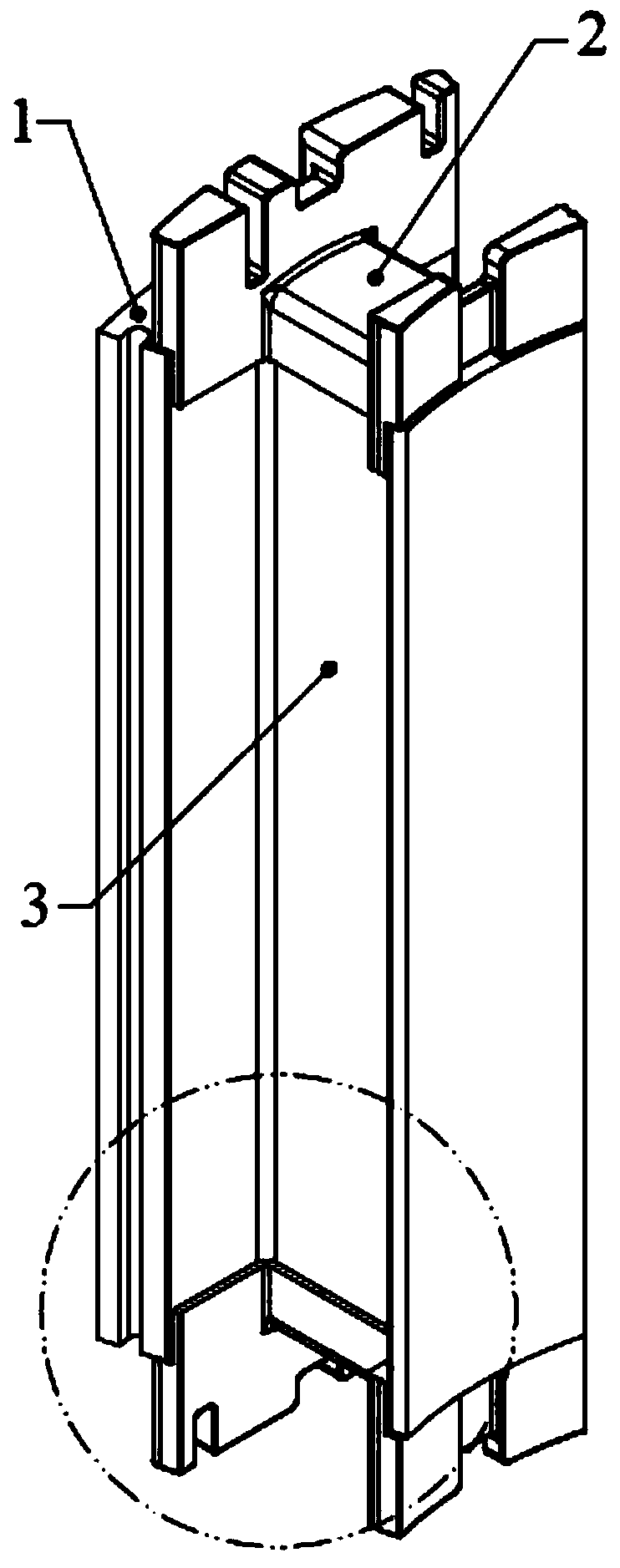

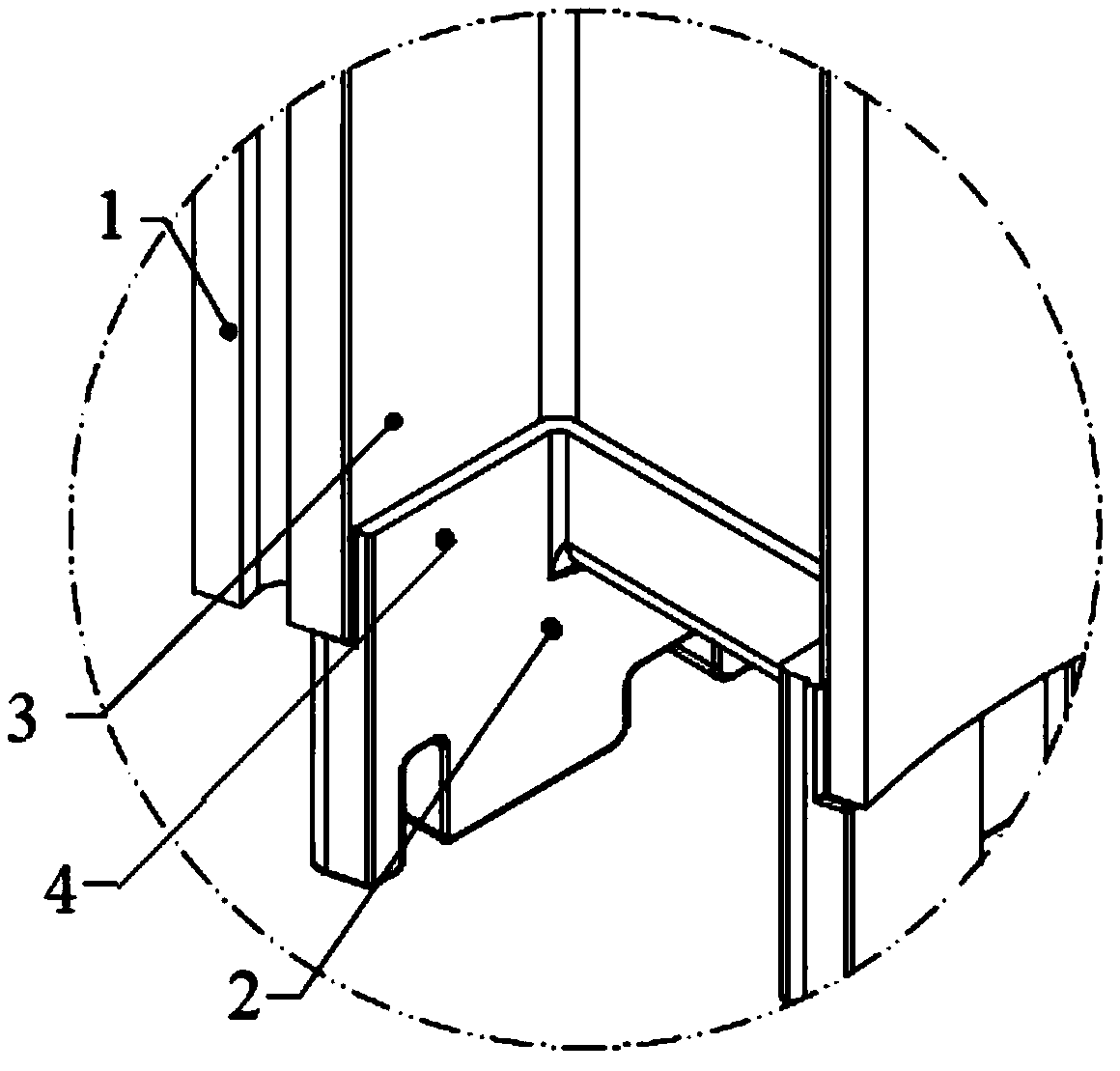

[0031] Such as Figure 4-6 As shown, an assembled centralized winding stator group includes a stator core 1, an insulating film 2 and an insulating paper 3. The stator core 1 is in the shape of a long strip, and the opposite sides of the stator core 1 are sunken inward to form a winding. The slot 8, the insulating film 2 is fixed on both ends of the stator core 1 through the fixing mechanism, and the insulating paper 3 is fixed in the winding slot 8 through the insulating film 2. The insulating paper 3 includes an insulating bottom for covering the bottom of the winding slot 8 and insulating side parts arranged on both sides of the insulating bottom. The fixing mechanism includes a fixing groove 6 arranged on the top of the stator core 1 and a fixing column 7 arranged on the bottom of the insulating film 2. The two ends of the insulating paper 3 are extended with a fixing piece 5, and the fixing piece 5 is arranged on the insulating film 2 and the stator iron. Between the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com