Graphene cleaning device

A cleaning device and graphene technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of wasting manpower and material resources, low graphene cleaning efficiency, etc., and reduce cleaning costs. , novel structure, high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below Figure 1-10 The specific implementation manner of the present invention will be described in further detail.

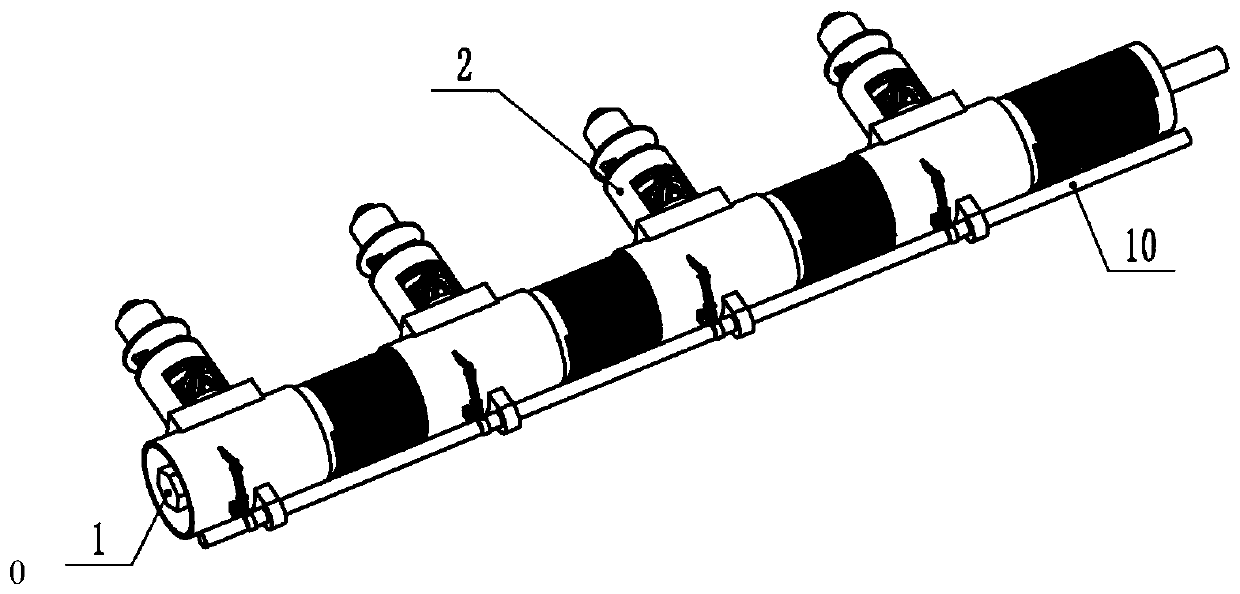

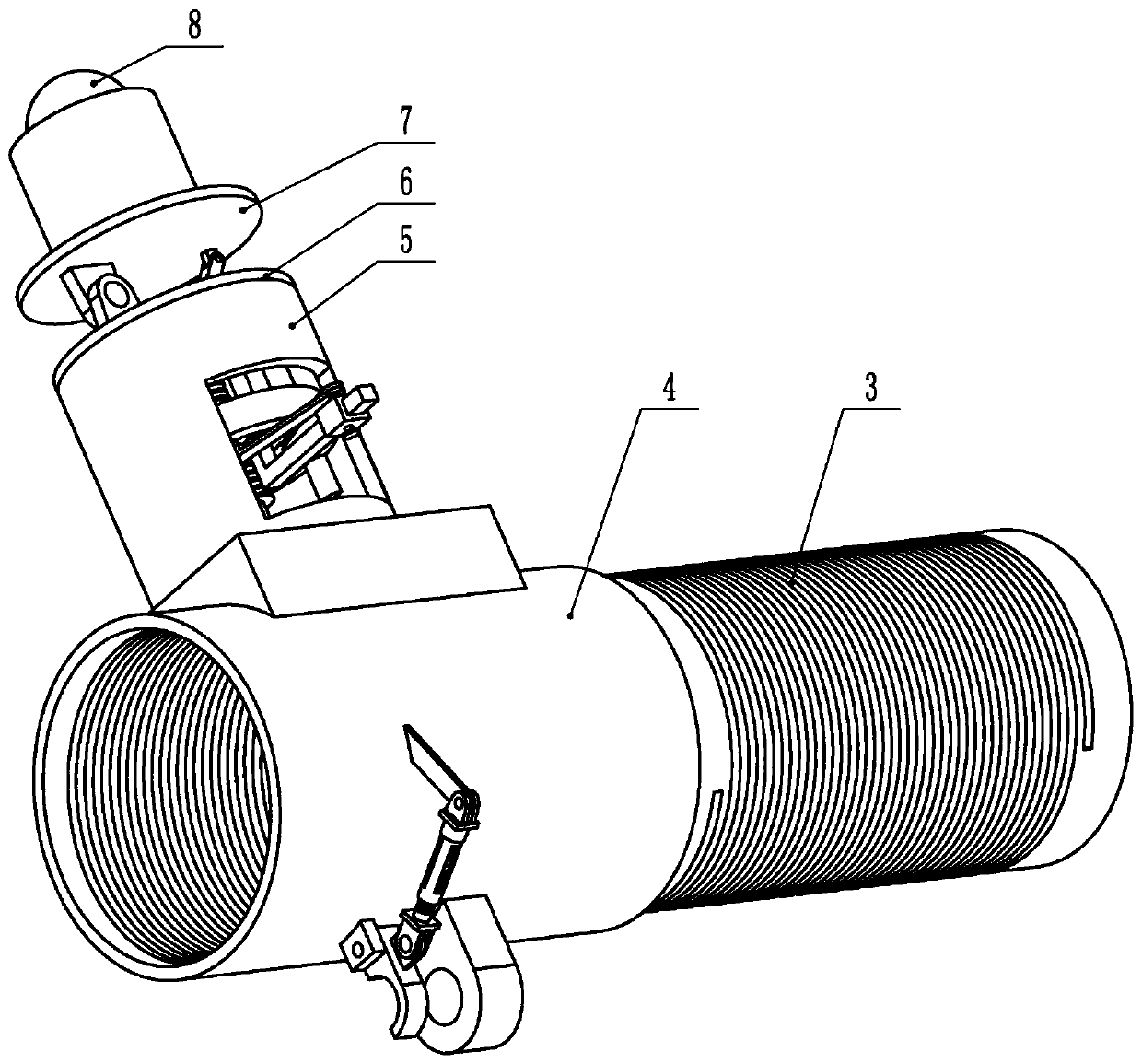

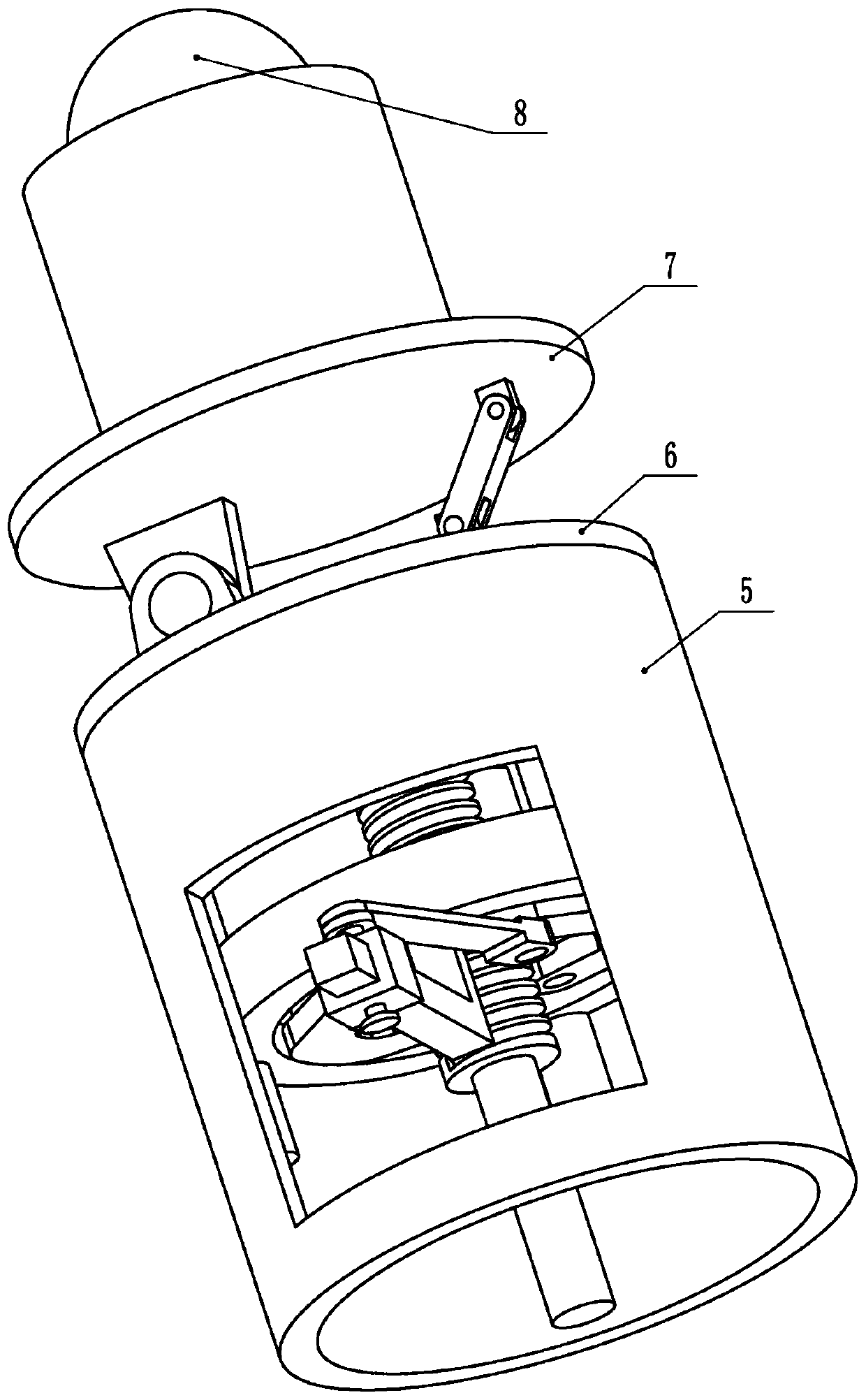

[0034] Depend on Figure 1-10 Given, the present invention includes a prismatic shaft 1, on which the prismatic shaft 1 is fitted with spray washing units 2 connected end to end;

[0035] The prismatic shaft 1 is the power input unit, and the prismatic shaft 1 is driven to rotate through external motors and other components. The rotation of the prismatic shaft 1 will drive the spraying unit 2 to perform corresponding actions, so that the spraying unit 2 will Clean the graphene to improve the cleaning efficiency.

[0036] The spraying unit 2 includes a sliding column 3, which is provided with a horizontal prismatic groove inside the sliding column 3, and the prismatic shaft 1 can slide through the prismatic groove, and the sliding column 3 can slide along the prismatic shaft 1 and follow the The structure in which the prismatic shaft 1 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com