Device for cleaning grinding head

A technology of cleaning device and grinding head, which is applied in the direction of grinding/polishing safety device, grinding/polishing equipment, surface polishing machine tool, etc., which can solve the problem of reduced cleaning efficiency and effect, long cleaning time, and inability to ensure cleanness and other problems, to achieve flexible and convenient installation, enhance local cleaning capabilities, and achieve the effect of focused cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

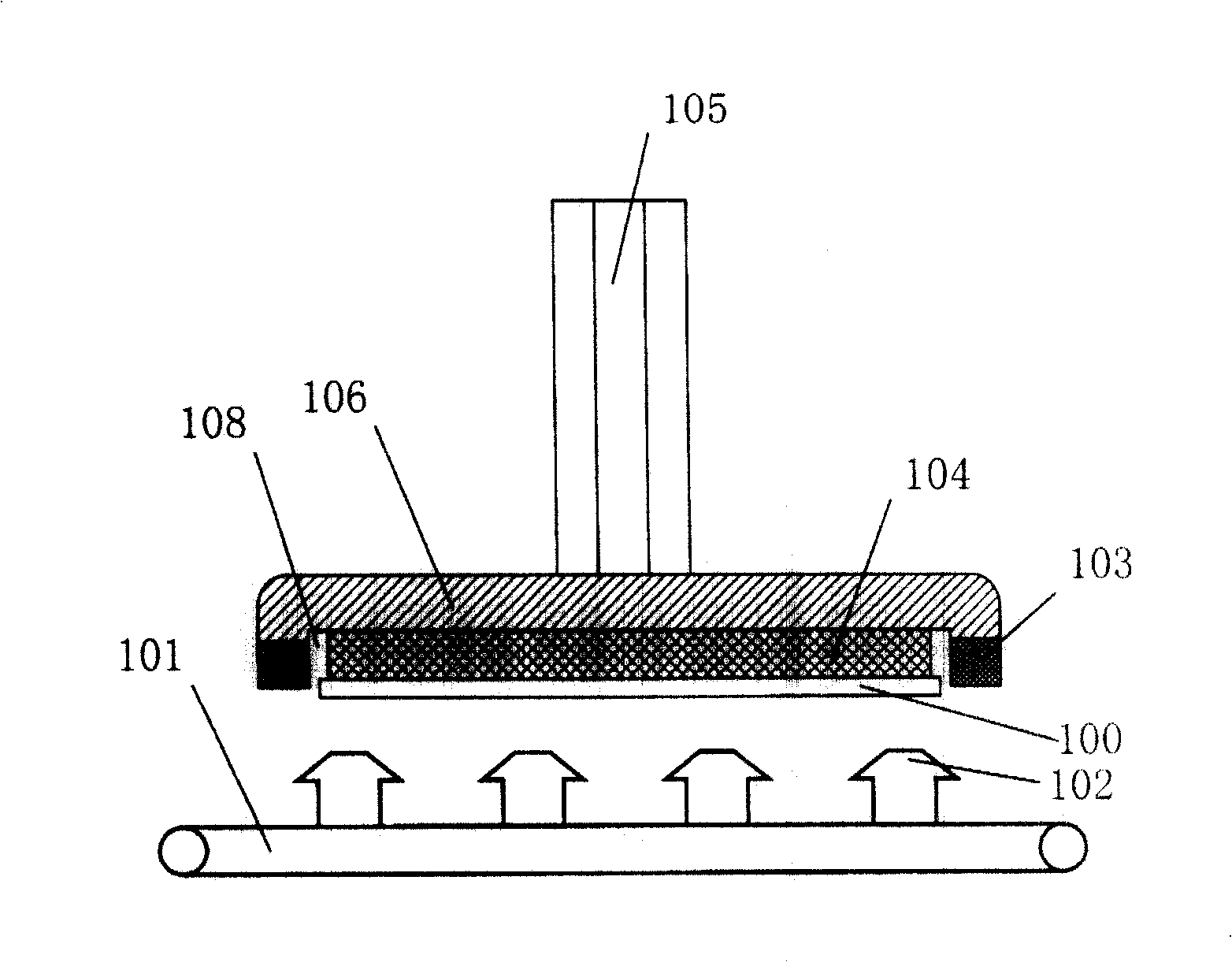

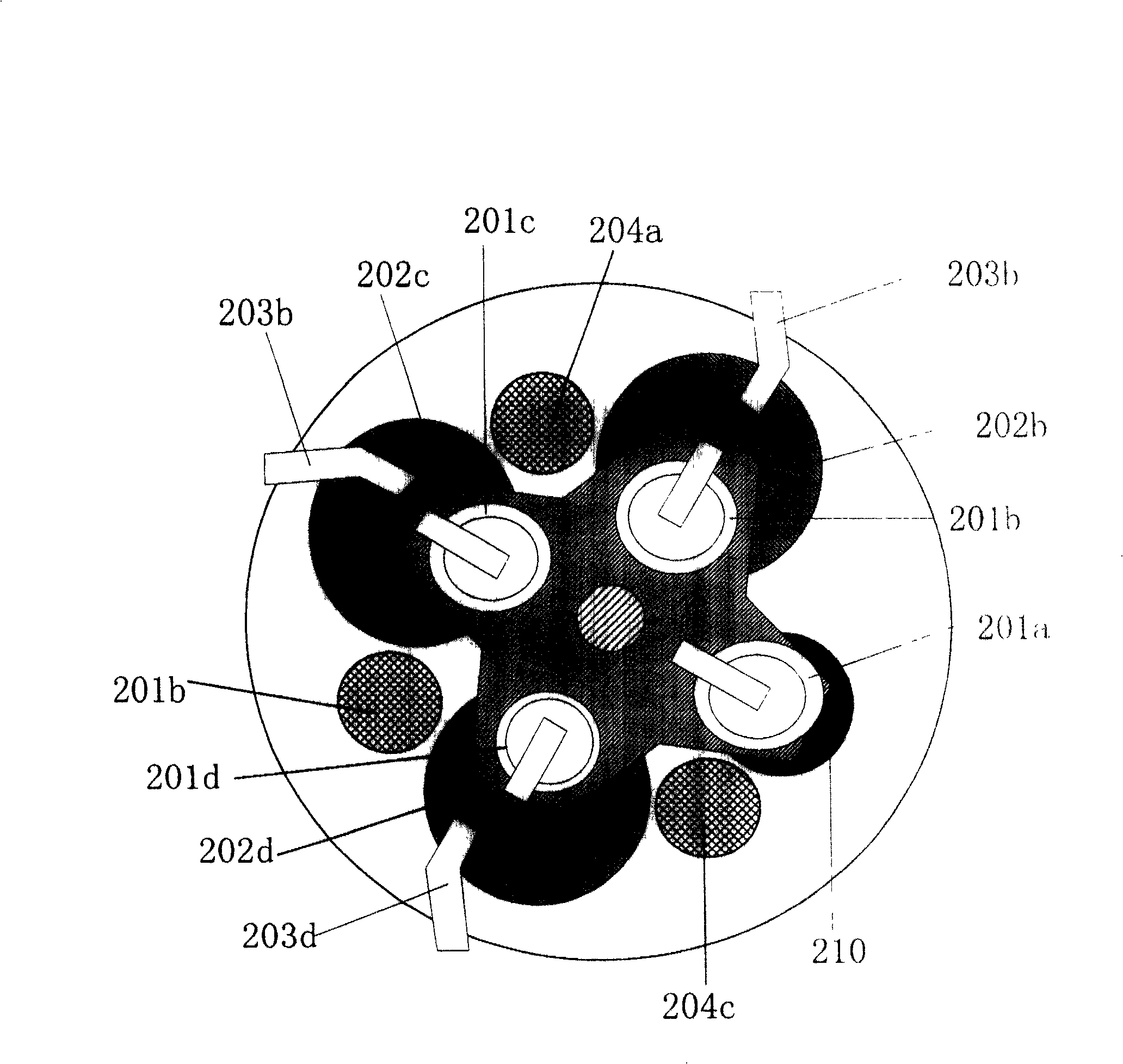

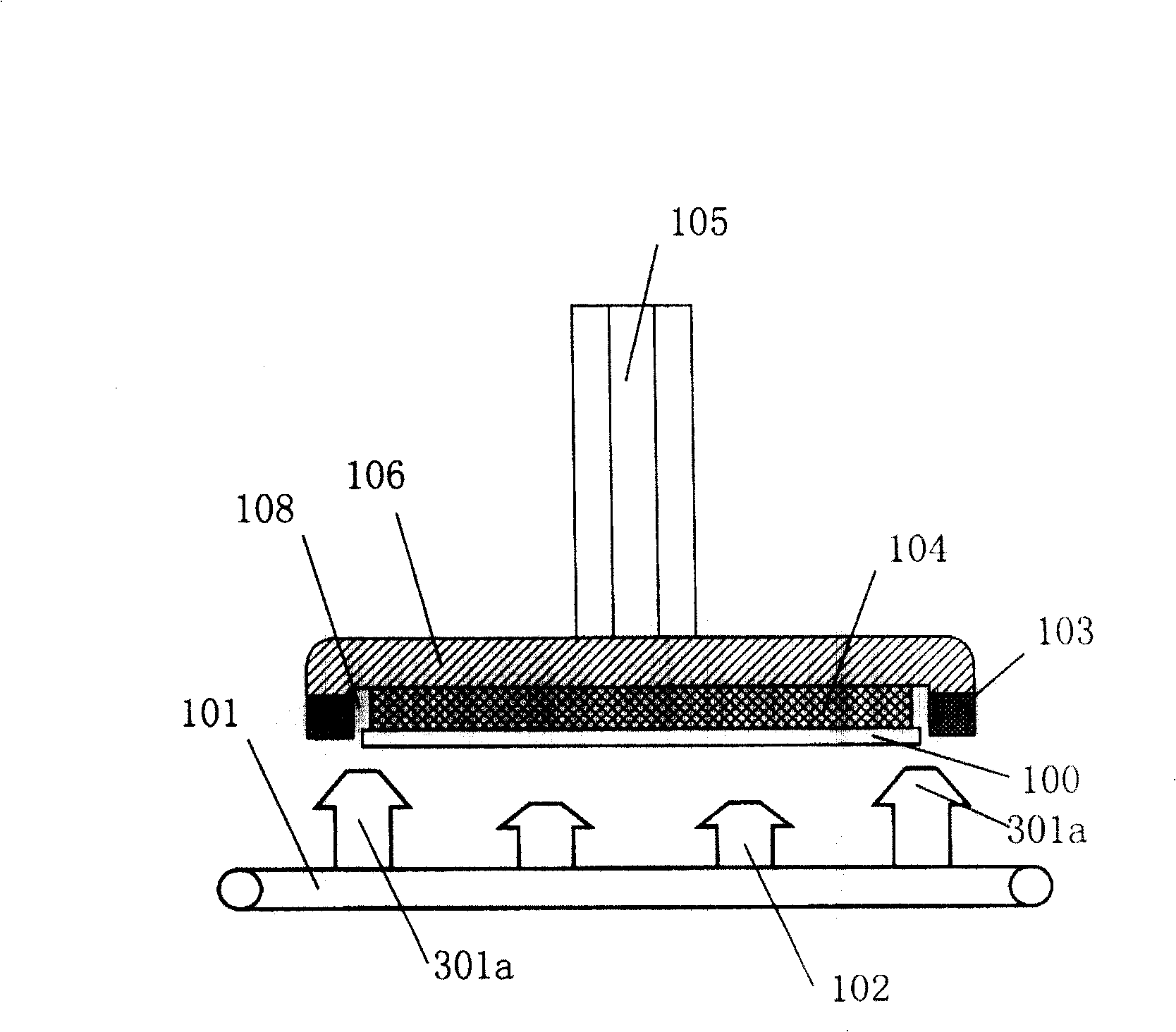

[0026] For the grinding of the same wafer, the grinding process can be divided into three stages: coarse grinding, fine grinding and fine grinding, and each stage has different requirements for polishing pad and slurry. stage, because of its lower grinding rate and higher flatness requirements, the used grinding pad will be denser and the particles of the grinding liquid will be finer. That is, in different grinding phases, different grinding pads and grinding fluids need to be used, so in the grinding process of wafers, the grinding head (head) holding the wafers needs to be moved between the grinding pads used in different grinding phases , for different stages of grinding, and at the same time, it is necessary to replace different grinding fluids at each stage. figure 2 It is a schematic diagram of grinding equipment adopting the cleaning device of the present invention, as figure 2 As shown, the equipment has four grinding heads 201a to 201d in total, three different gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com