A device and method for rapid production of laminated boards

A laminated plate, rapid technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of poor pouring quality, difficulty in mass production, and low efficiency of concrete use, so as to improve stability, improve production efficiency, and improve The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

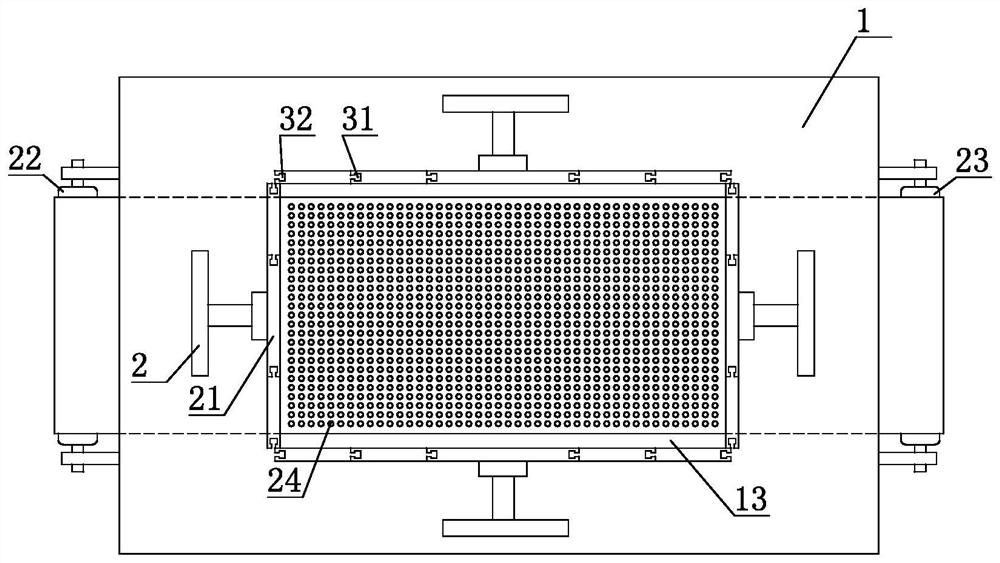

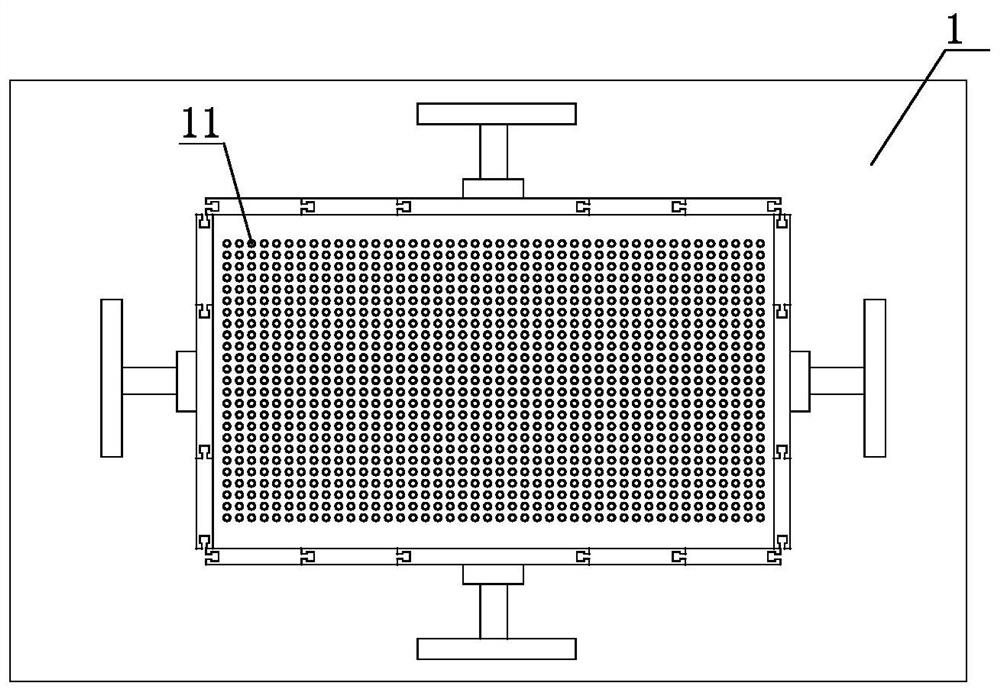

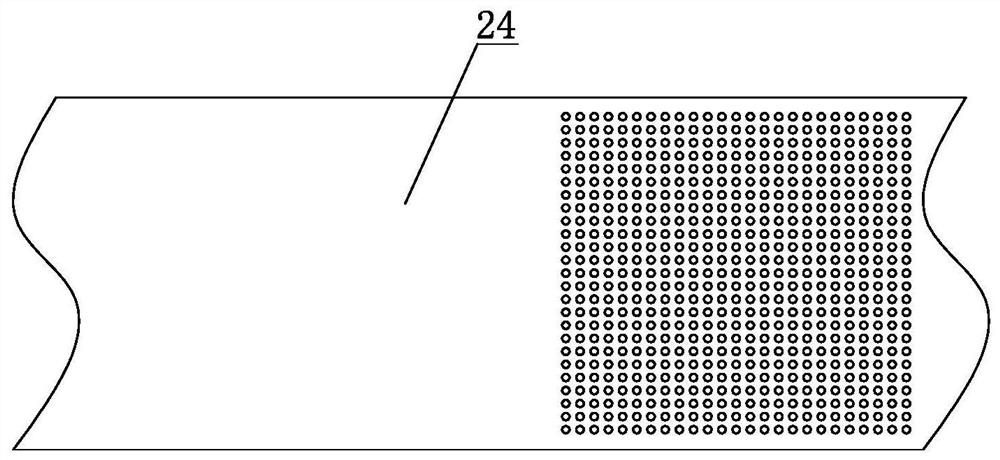

[0042] The present invention is a kind of equipment for rapid production of laminated boards, including a bearing base 1, the lower part of the bearing base 1 is provided with a leakage hole 11, and the leakage hole 11 is used for the outflow of excess water in the process of making the laminated board, The lower part of the bearing base 1 is provided with a placing seat 12, and the placing base 12 is fixed on the ground or other relatively stable bases. The bearing base 1 is provided with a forming area 13, and the forming area 13 includes four Electric cylinder 2, the electric cylinder 2 is distributed in a rectangular shape, the output end of the electric cylinder 2 is provided with a baffle 21, and the baffle 21 contacts to form a closed space, which is used for forming laminated plates, and the bearing One side of the base 1 is provided with a driving roller 22, and the other side is provided with a driven roller 23, and a filter screen 24 is arranged between the driving r...

Embodiment 2

[0055] The present invention is a kind of equipment and method for rapid production of laminated boards. On the basis of Embodiment 1, in order to speed up the rapid prototyping of laminated boards, a docking hole 61 is provided on the bearing base 1, and the bearing base 1 The upper part is provided with a heating plate 62. The heating plate 62 is provided with a heating wire 63. The heating wire 63 corresponds to the molding area 13. The heating plate 62 is provided with a docking column 64, and the docking column 64 is connected to the butt joint. The holes 61 are connected, and the heating plate 62 can heat the molding area 13 to speed up the water loss in the molding area 13 and speed up the rapid molding of the laminated board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com