Multifunctional labeling machine capable of pasting three labels

A multi-functional, labeling machine technology, applied in the direction of labeling, labeling machines, labels, etc., can solve the problems of low production efficiency, pasting multiple labels, cumbersome production steps, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments of the drawings.

[0027] Preferably, in the label tape 19 of the present invention, the label papers on it are evenly arranged on the bottom paper separated by a certain distance from each other. Therefore, when the label paper is attached to the packaging bottle 3, there is no need to perform the label tape 19 Cutting.

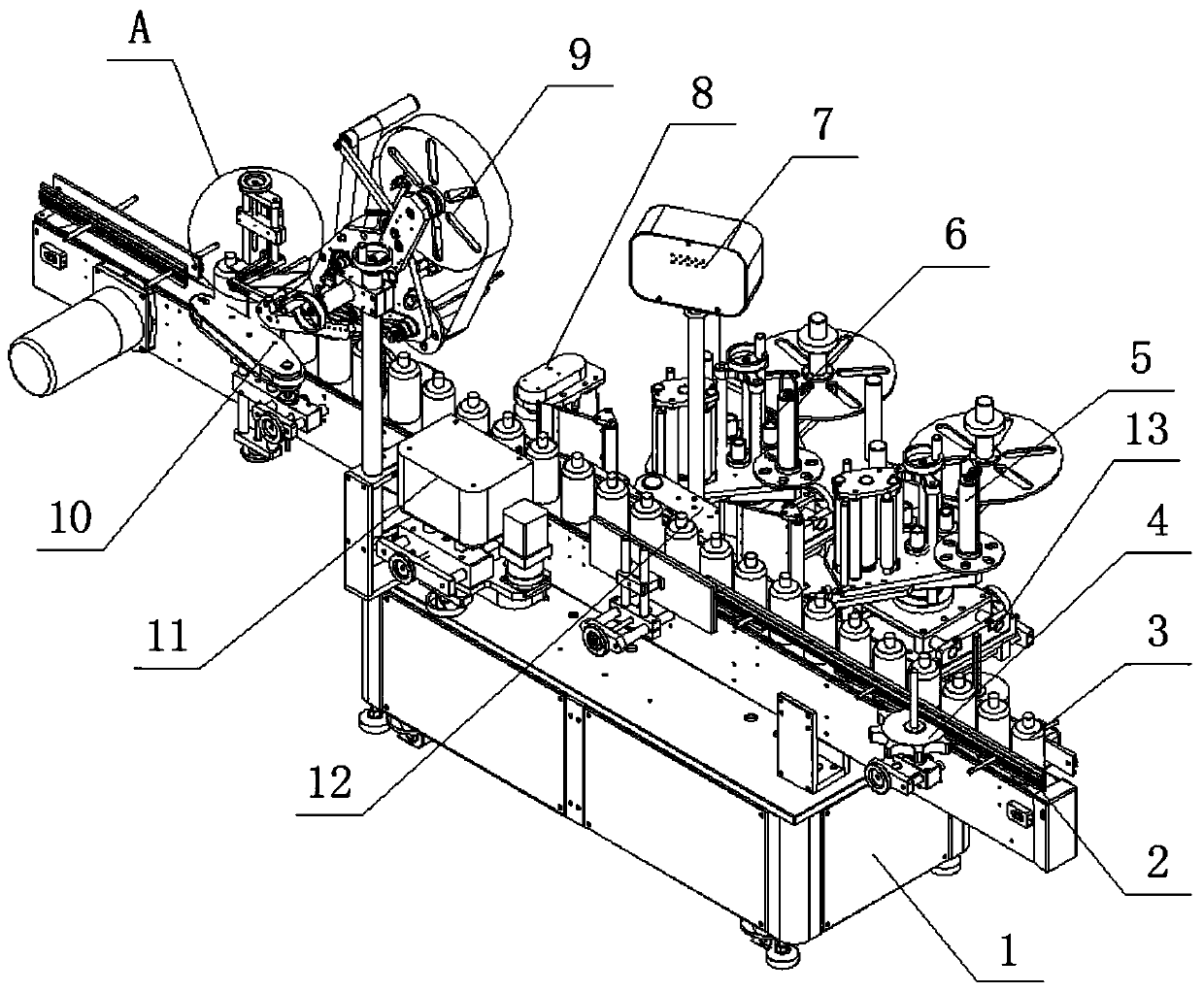

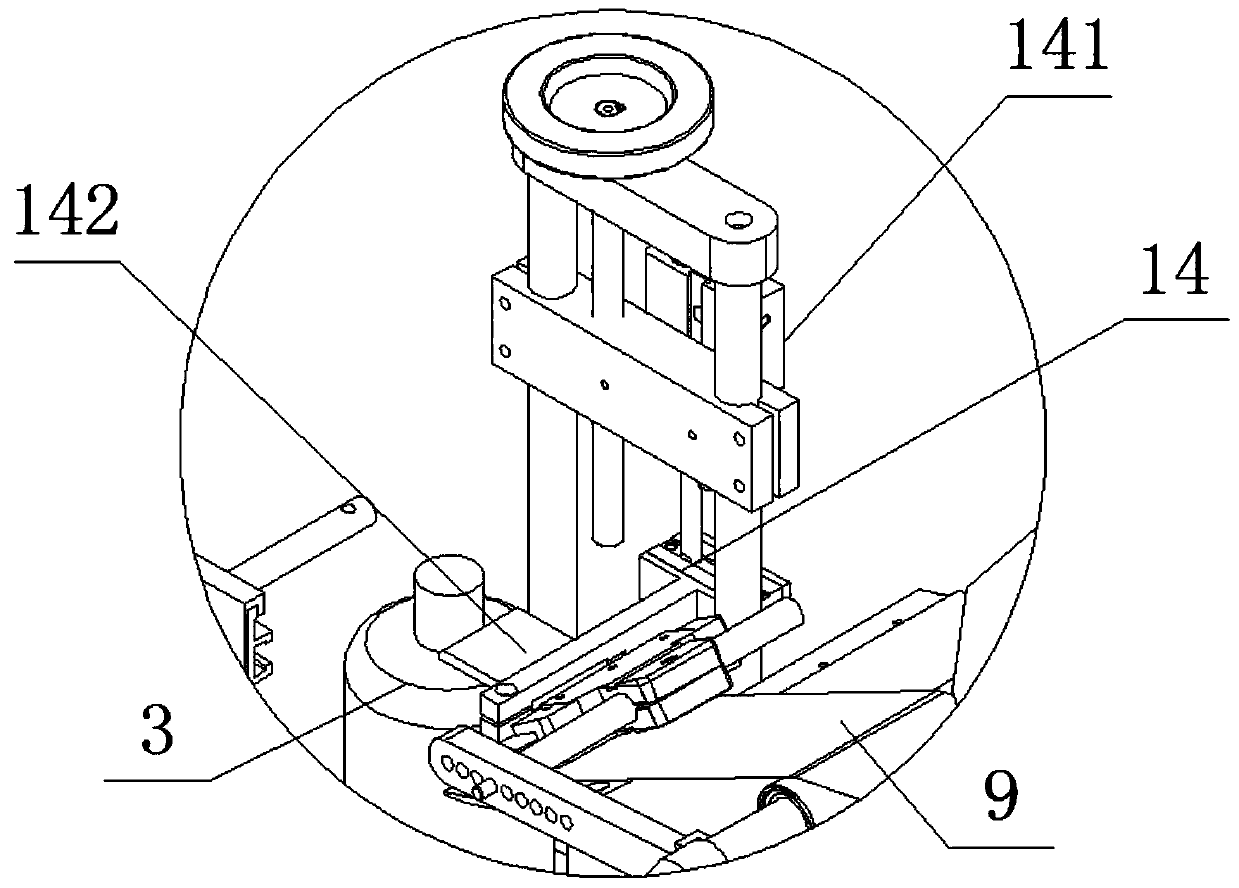

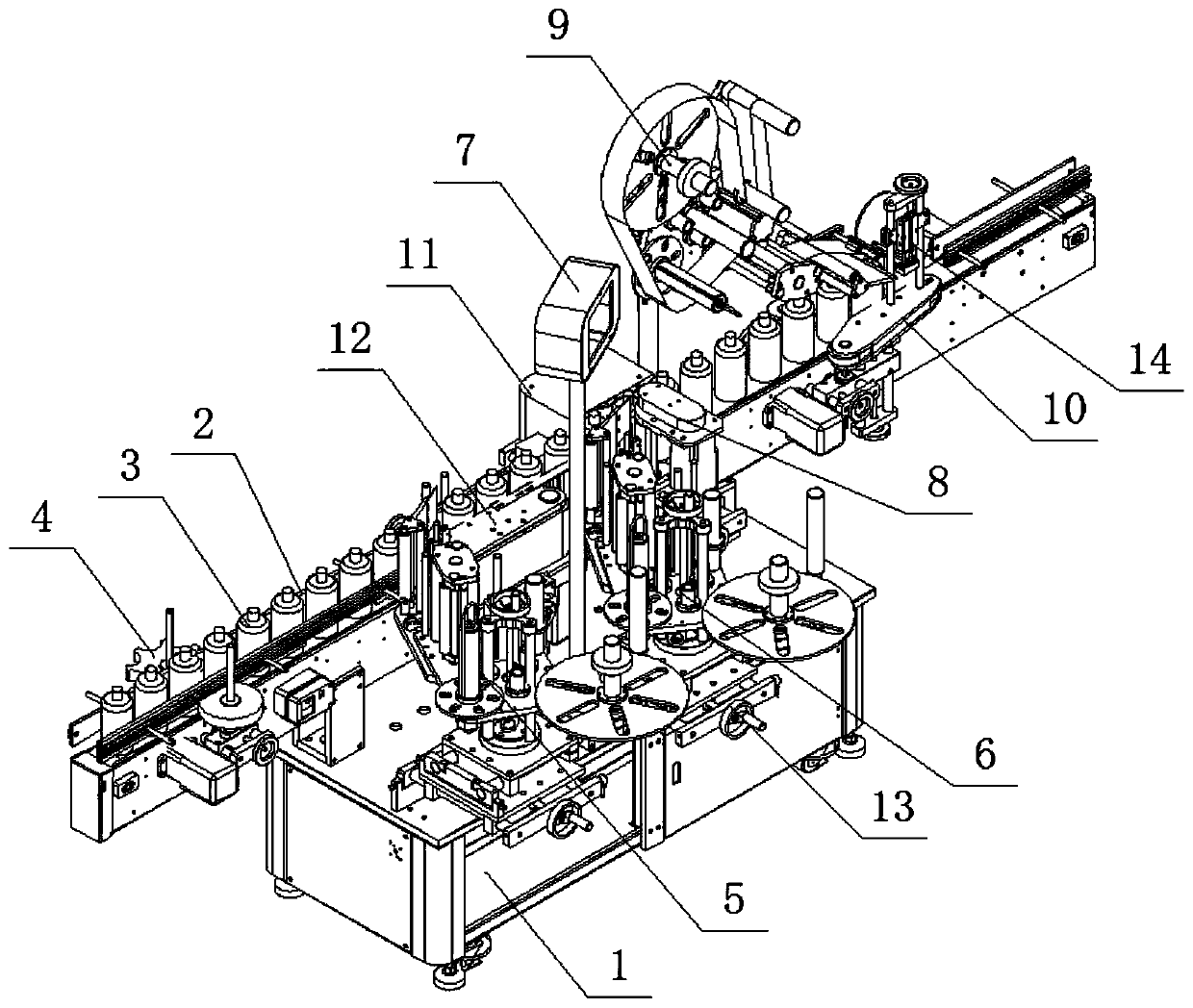

[0028] Such as figure 1 , image 3 As shown, a multifunctional labeling machine capable of sticking three labels is installed on a frame 1, and includes a conveyor belt set on a prescribed path, a bottle separating assembly 4, a first labeling mechanism 5, and a first labeling assembly 12. The feed assembly 11, the second labeling mechanism 6, the auxiliary labeling assembly 8, the third labeling mechanism 9, the clamping assembly 10, and the second pressing assembly 14.

[0029] Wherein, the bottle separating assembly 4 is arranged at the feeding end of the conveyor b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap