A kind of preparation method of elastic chiffon fabric

A fabric and elastic technology, applied in the field of elastic chiffon fabric preparation, can solve the problems of elastic chiffon product quality and complex processing process, and achieve the effects of easy control of processing technology, durable and stable elasticity, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Method for preparing elastic chiffon fabric, the process is as follows:

[0038] (1) PET (characteristic viscosity of 0.63 dl / g) and PBT (characteristic viscosity of 1.19 dl / g) by mass ratio of 50:50, it is obtained by preparing FDY wire in the process of FDY process and circular composite fiber. The low elastic polyester fiber is specifically:

[0039] The FDY process is: the spinning temperature of 277 ° C, the temperature of the spinning case corresponding to the PET is 283 ° C, the temperature of the spinning box corresponding to the PBT is 272 ° C, the cooling temperature is 23 ° C, one roller speed 2170m / min, one roller The temperature is 83 ° C, the two-roll speed is 3460 m / min, the two-roll temperature is 200 ° C, the winding speed is 3390 m / min;

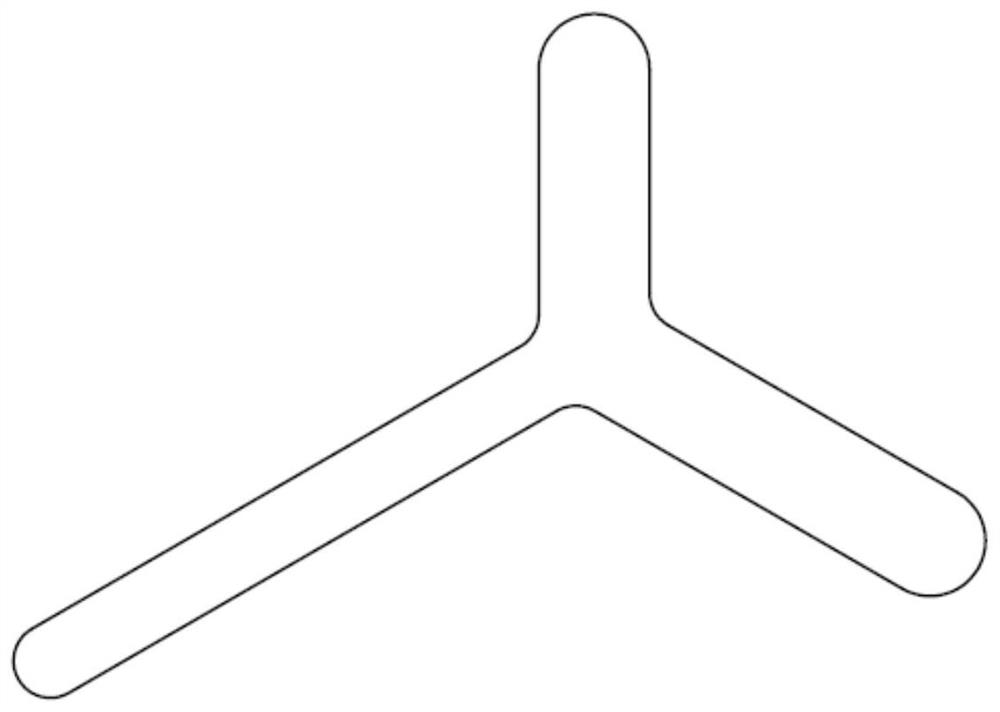

[0040] The proportion of the spinneret on the spinneret is changed from a circular shape to a trio shape, the ratio of the three-leaf length of the same three leafless spray hole is 1.0: 1.1: 2.0, the ratio of th...

Embodiment 2

[0046] Method for preparing elastic chiffon fabric, the process is as follows:

[0047] (1) PET (characteristic viscosity is 0.62 dl / g) and PBT (characteristic viscosity of 0.62 dl / g) and PBT (characteristic viscosity is 1 dl / g) by mass ratio of PET (characteristic viscosity is 1 dl / g) to prepare FDY wire, ie Popolyester fiber, specifically:

[0048] The FDY process is: spinning temperature 278 ° C, the temperature of the spinning case corresponding to the PET is 283 ° C, the temperature of the spinning case corresponding to the PBT is 270 ° C, the cooling temperature is 24 ° C, a roller speed 2180 m / min, one roll Temperature 83 ° C, two-roller speed 3470 m / min, the two-roll temperature is 208 ° C, winding speed 3400 m / min;

[0049] The proportion of the spinneret on the spinneret is changed from a circular shape to a trio shape, the ratio of the three-leaf length of the same three leaf spine is 1.0: 1.4: 2.0, the ratio of the corresponding three-leaf width is 1.5: 1...

Embodiment 3

[0055] Method for preparing elastic chiffon fabric, the process is as follows:

[0056] (1) PET (characteristic viscosity is 0.62 dl / g) and PBT (characteristic viscosity of 0.2 dl / g) by mass ratio of 50:50, the FDY wire is prepared according to the process of FDY process and circular and circular composite fibers. The low elastic polyester fiber is specifically:

[0057] The FDY process is: the temperature of the spinning temperature of 278 ° C, the temperature of the spinning case corresponding to the PET is 281 ° C, the temperature of the spinning case corresponding to the PBT is 275 ° C, the cooling temperature is 25 ° C, one roller speed 2200m / min, one roller The temperature is 85 ° C, the second roll speed is 3500 m / min, the two-roll temperature is 206 ° C, the winding speed is 3410 m / min;

[0058] The proportion of the spinneret on the spinneret is changed from a circular shape to a trio shape, the ratio of the three-leaf length of the same three leaf spinning hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com