Biomass hot blast stove

A hot blast stove and biomass technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of short heat exchange time, few flue gas return trips, affecting the service life of hot blast stoves, etc. Heat exchange effect, the effect of reducing the dead angle of blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

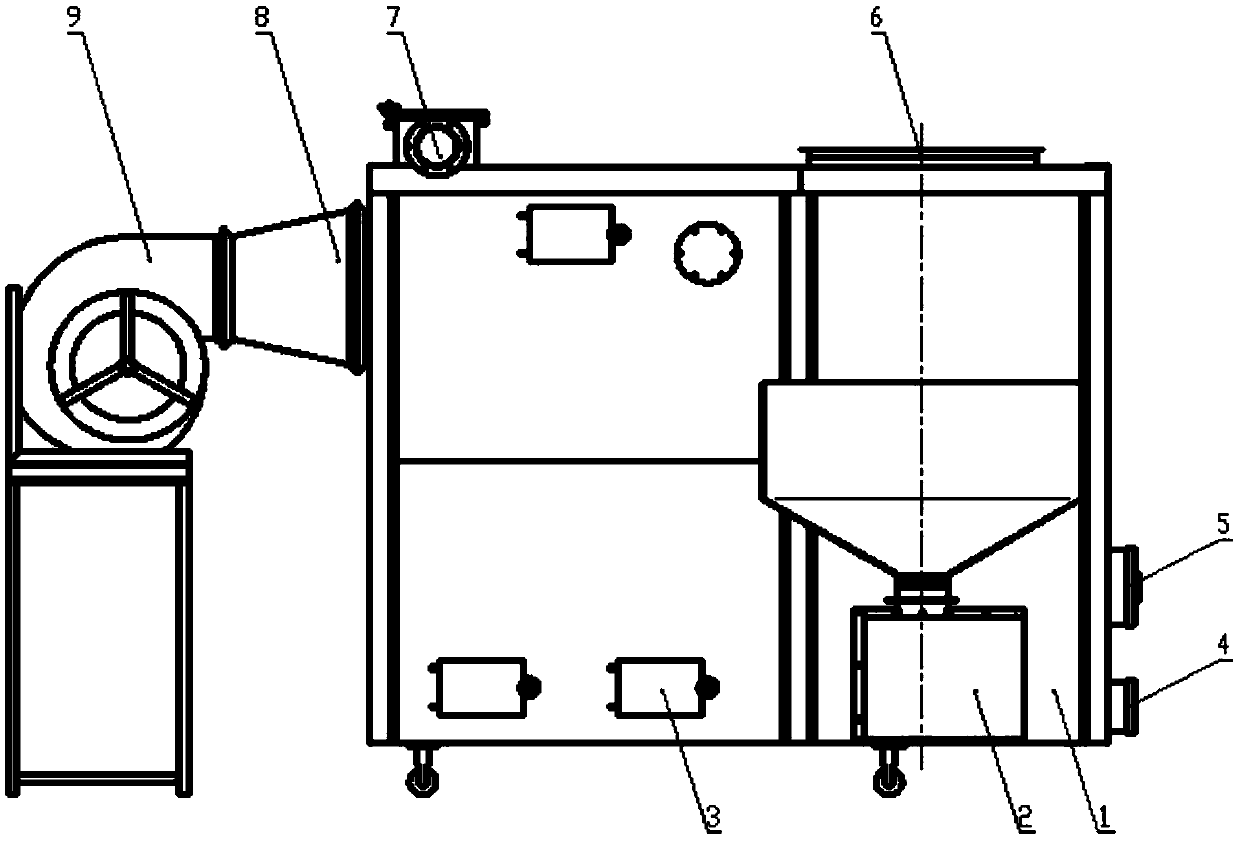

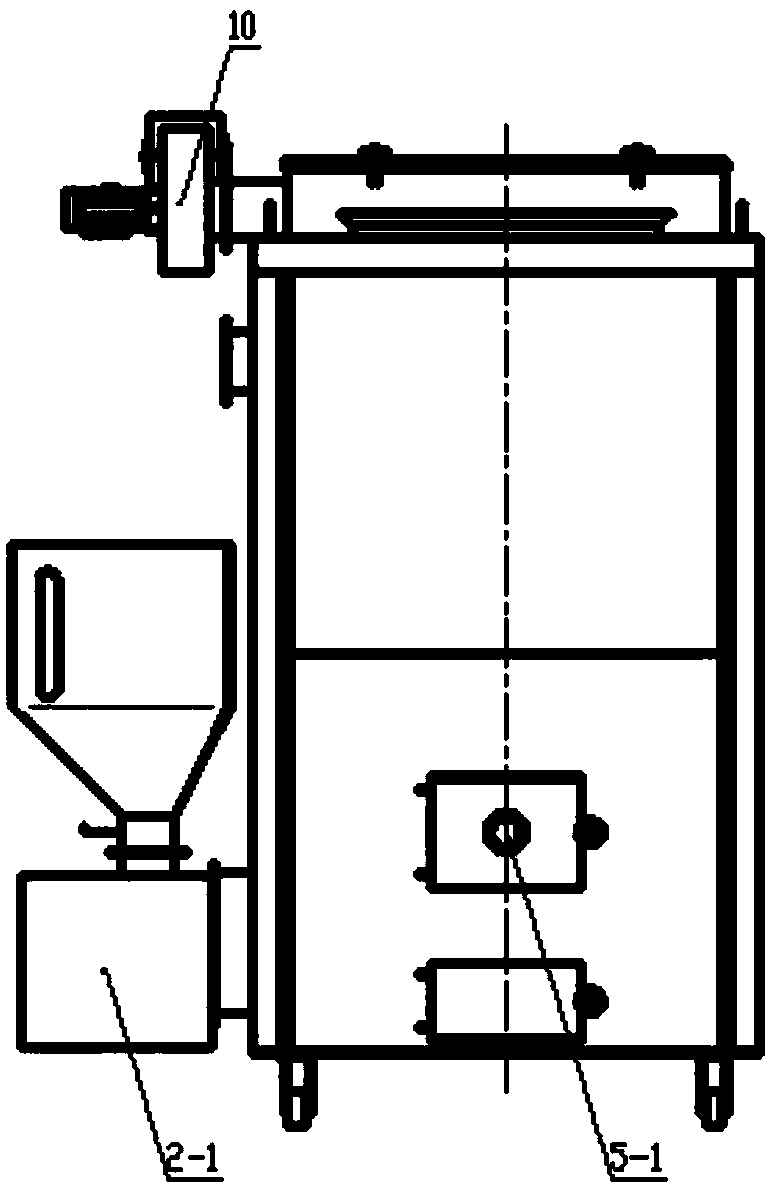

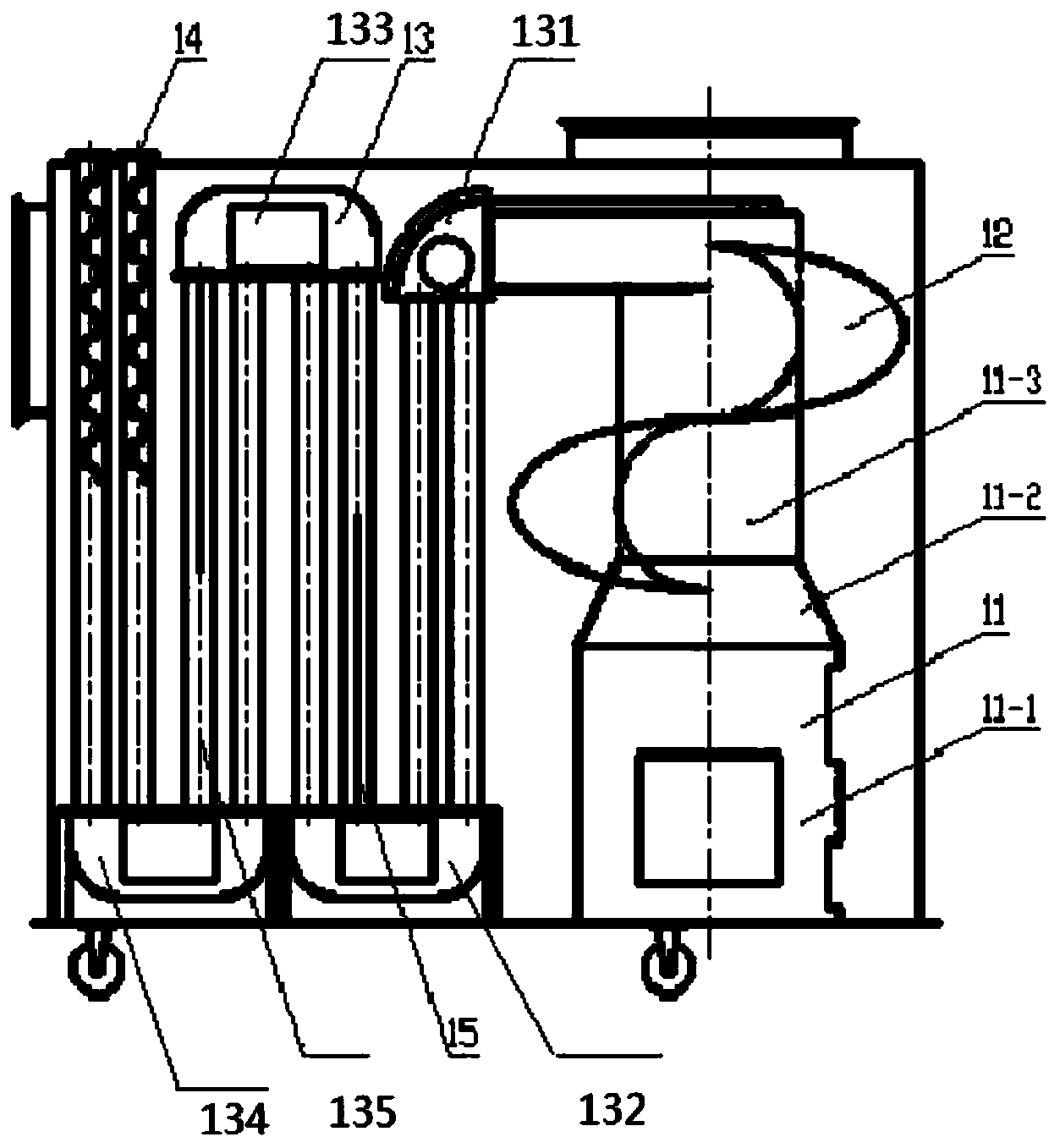

[0016] According to one embodiment, the feeding device 2 is connected to the body 1 through, for example, a flange; the furnace 11 communicates with the upper part of the heat exchanger 13 and is placed inside the body 1; the heat exchanger 13 There is the soot cleaning port 3 on the side; the slag outlet 4 and the fire viewing port 5 are located on the side of the body 1; the fire viewing port 5 has a fire viewing hole 5-1. According to one embodiment, the fire viewing hole 5-1 is circular, high temperature resistant transparent glass. The air outlet 6 is directly above the furnace 11 and is located on the top of the body 1; the smoke outlet 7 is directly above the last return pipe of the heat exchanger 13 and is located on the top of the body 1; A boiler exhaust fan 10 is installed on the smoke outlet 7; the air inlet 8 is located on the left side of the body 1; a blower 9 is installed on the air inlet 8. It should be noted that in the description of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com