Horizontal type hot blast stove

A hot blast stove, horizontal technology, applied in the field of horizontal vertical fire tube hot blast stove, can solve the problems of reducing the comfort of the breeding environment, unavoidable heat dissipation wind, unfavorable for cleaning carbon deposits, etc., and achieve the effect of strengthening heat transfer and realizing Automatic furnace sealing function to improve the combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

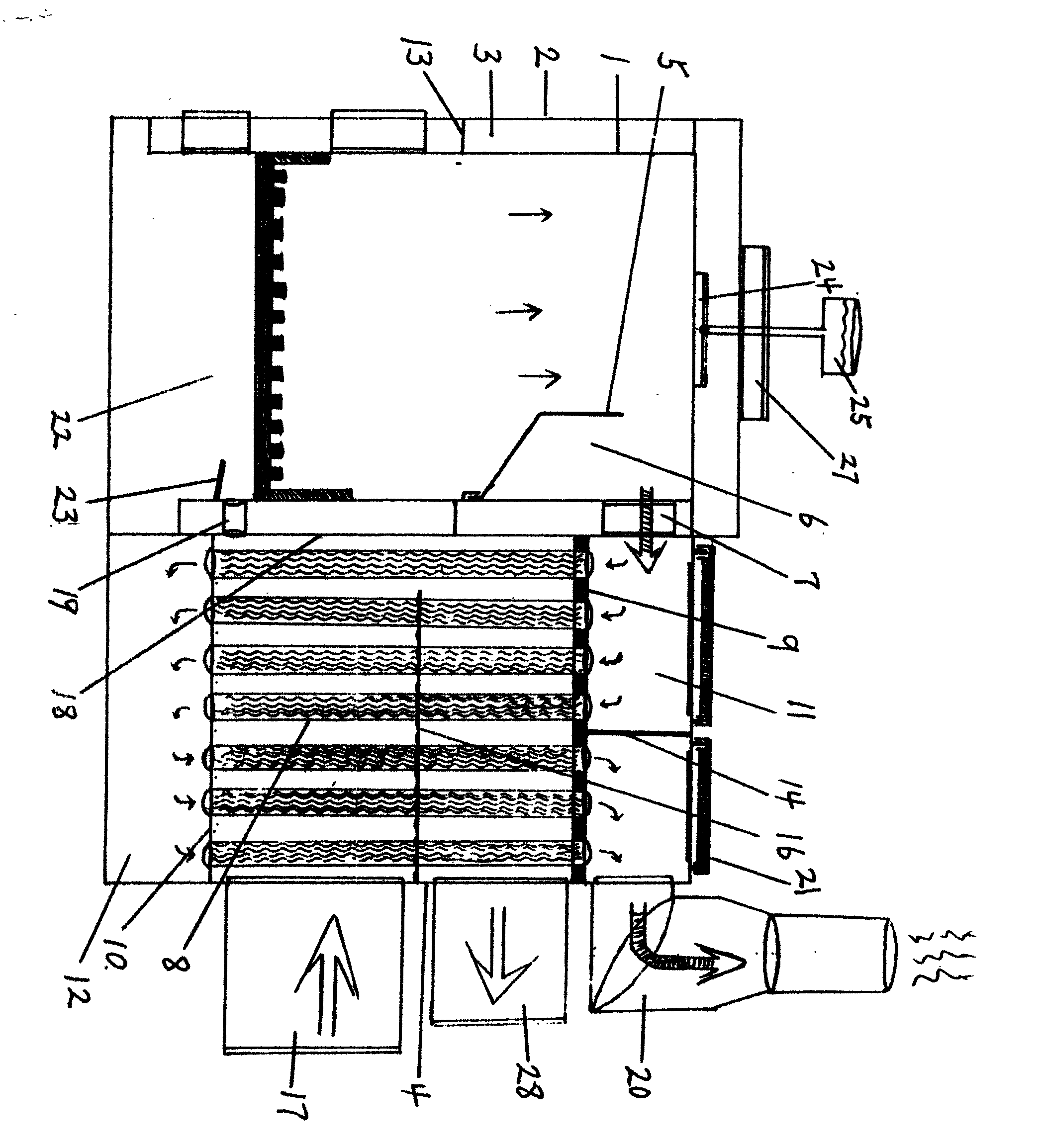

[0021] The hot blast stove is divided into two parts, a relatively independent combustion chamber and a radiator. Above the combustion chamber, there is a buffer plate 5 and a settling chamber 6 formed by the buffer plate. There is a high-temperature flue gas outlet 7 leading to the smoke chamber on the first stroke of the radiator near the radiator.

[0022] There is an air-cooled interlayer 3 between the combustion chamber liner 1 and the shell 2, and an air-cooled interlayer at the top of the combustion chamber. The radiator shell 4 and the combustion chamber shell are essentially integral structures.

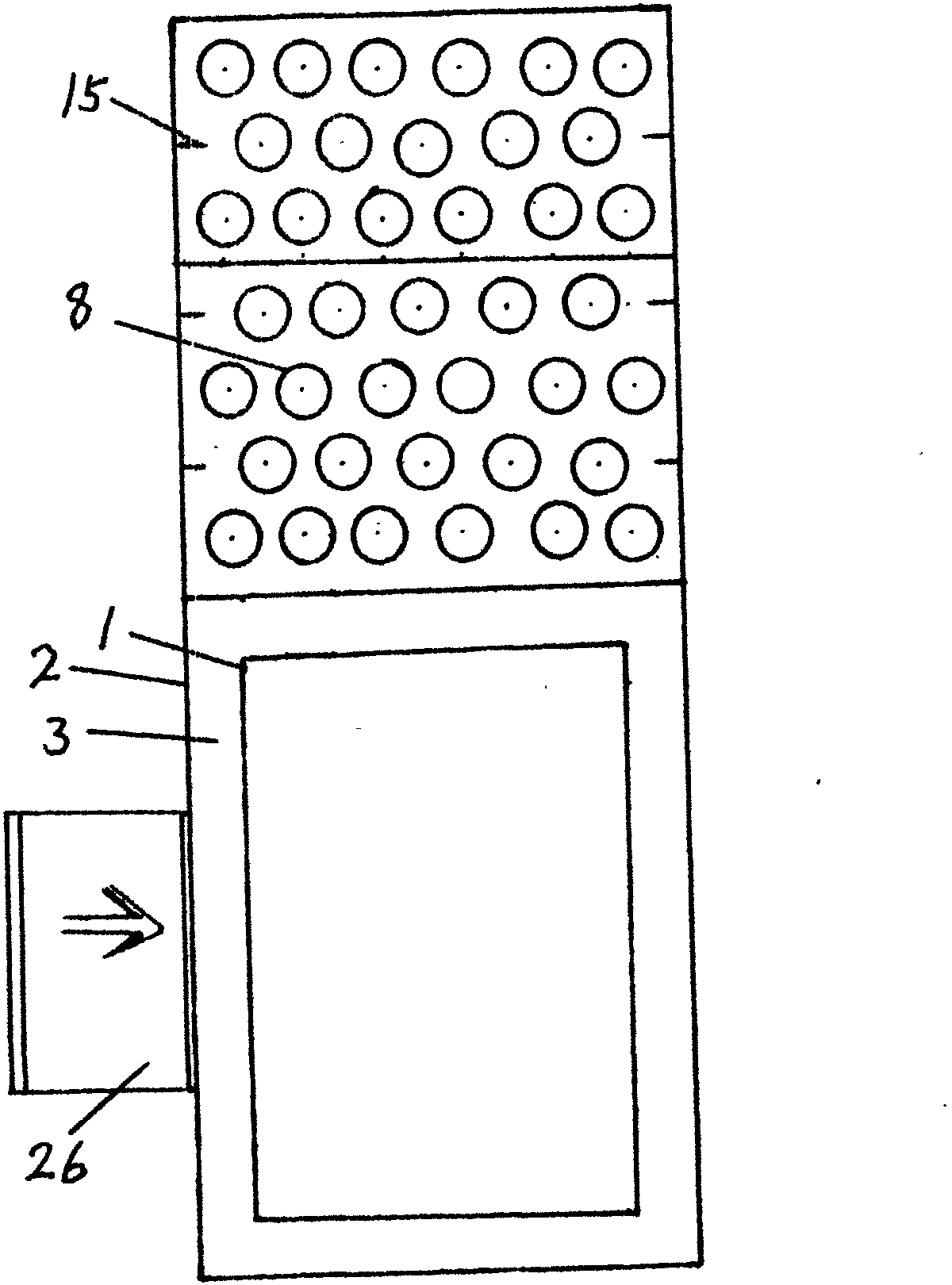

[0023] The pyrotechnic tube bundle composed of pyrotechnic tubes 8 is between the upper tube plate 9 and the lower tube plate 10, the upper tube plate is the upper smoke chamber 11, and the lower tube plate is the lower smoke chamber 12.

[0024] A transverse partition 13 is arranged between the interlayer of the combustion chamber and the outer casing. The transverse partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com