Short-cut yarn material raising type drying device

A drying device and chopped yarn technology, applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems of inability to air-dry chopped strands, difficult to collect, and chopped strands are easy to float everywhere, etc., and achieve high efficiency , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

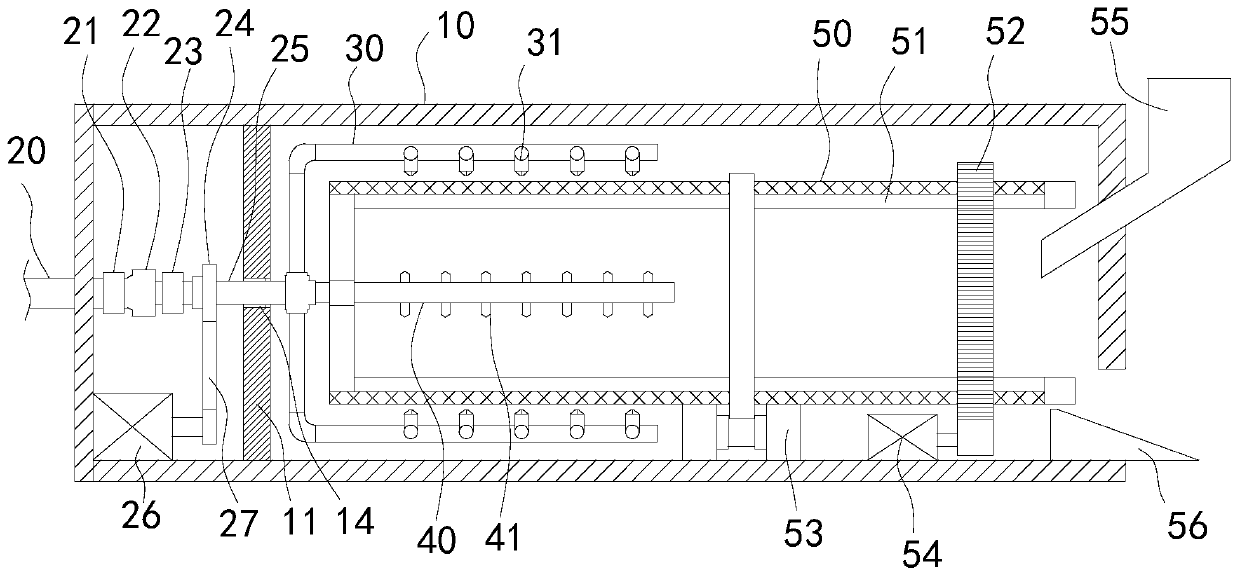

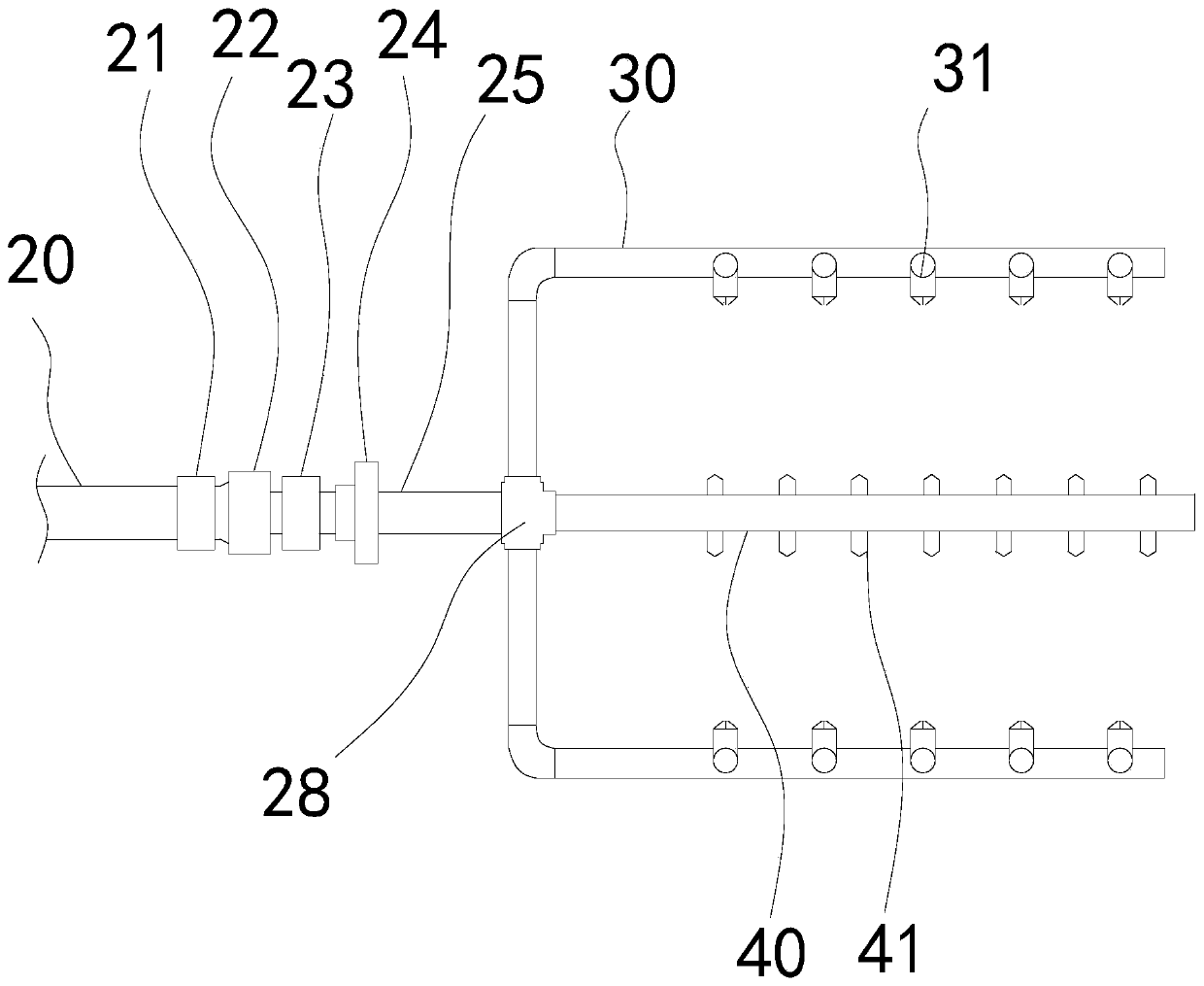

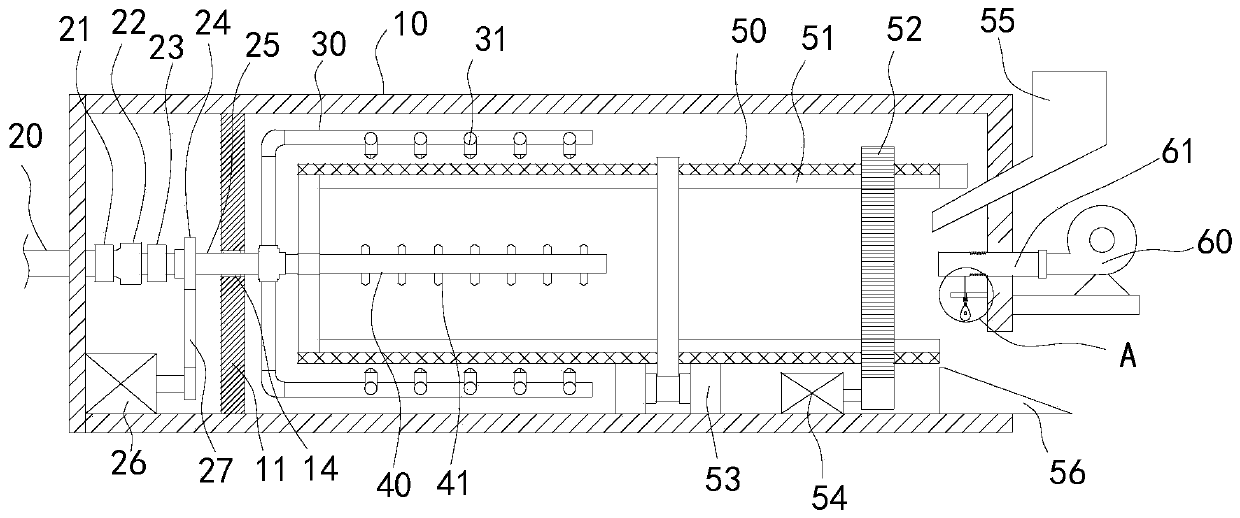

[0023] Such as figure 1 , figure 2 As shown, the present invention provides a kind of chopped yarn raising type drying device, comprising:

[0024] Housing 10, the inside of the left side of the housing 10 is provided with a partition 11, and the bottom right side of the housing 10 is provided with a discharge port;

[0025] A feeding device, the feeding device is arranged in the housing 10 and is located on the right side of the partition 11, wherein the feeding device includes a drum 50, and the left side of the drum 50 is sealed , the left end of the rotating drum 50 can be sealed with a sealing plate, and the right side of the rotating drum 50 can be provided with an opening to facilitate feeding. The bottom end of the opening can extend to the inside of the drum 50, and the bottom of the opening is provided with a discharge plate 56, and the discharge plate 56 can be a plate with a slope. When discharging, the chopped strands will directly fall onto the discharge plat...

Embodiment 2

[0032] Such as figure 1 , figure 2 As shown, the present invention provides a kind of chopped yarn raising type drying device, comprising:

[0033] Housing 10, the inside of the left side of the housing 10 is provided with a partition 11, and the bottom right side of the housing 10 is provided with a discharge port;

[0034]A feeding device, the feeding device is arranged in the housing 10 and is located on the right side of the partition 11, wherein the feeding device includes a drum 50, and the left side of the drum 50 is sealed , the left end of the rotating drum 50 can be sealed with a sealing plate, and the right side of the rotating drum 50 can be provided with an opening to facilitate feeding. The bottom end of the opening can extend to the inside of the drum 50, and the bottom of the opening is provided with a discharge plate 56, and the discharge plate 56 can be a plate with a slope. When discharging, the chopped strands will directly fall onto the discharge plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com