A thermal protection installation structure of a pressure sensor in a narrow space

A pressure sensor and installation structure technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as inaccurate measurement of pressure sensors, harsh measurement environments, and limited installation space, and achieve good thermal stability. Protective effect, extend the heat transfer path, and improve the effect of anti-vibration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following Examples and drawings of the present invention, the technical solutions of the present invention are clearly and completely described, obviously, not to limit the described embodiment of the present invention.

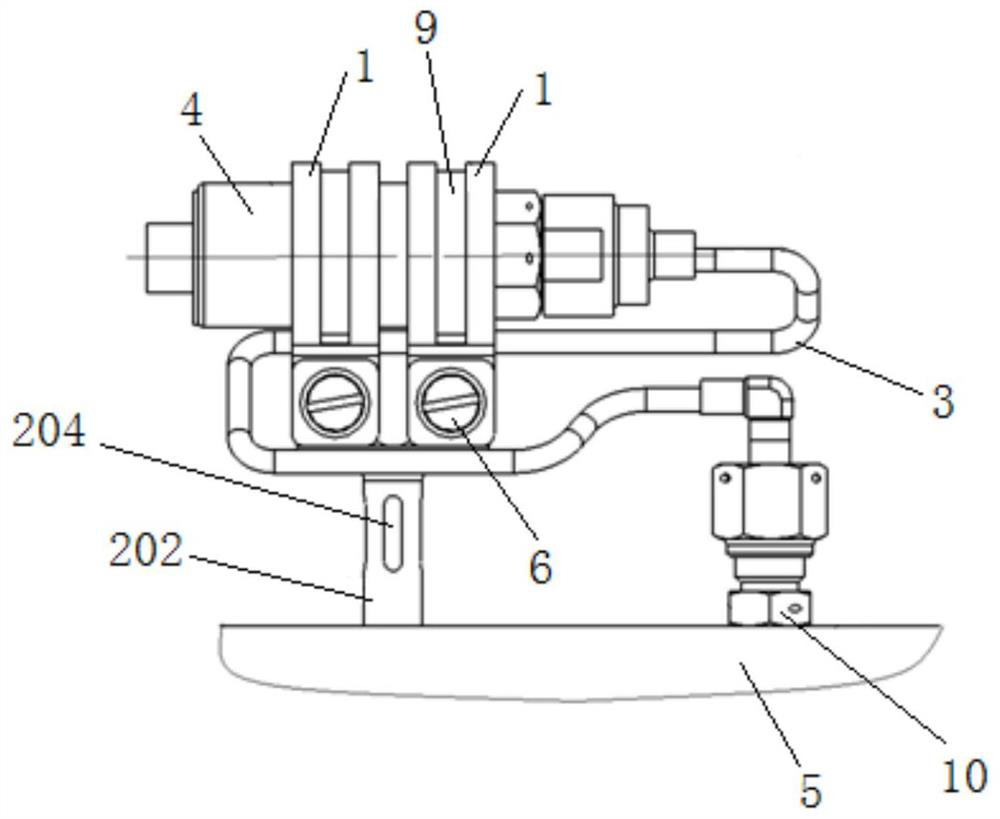

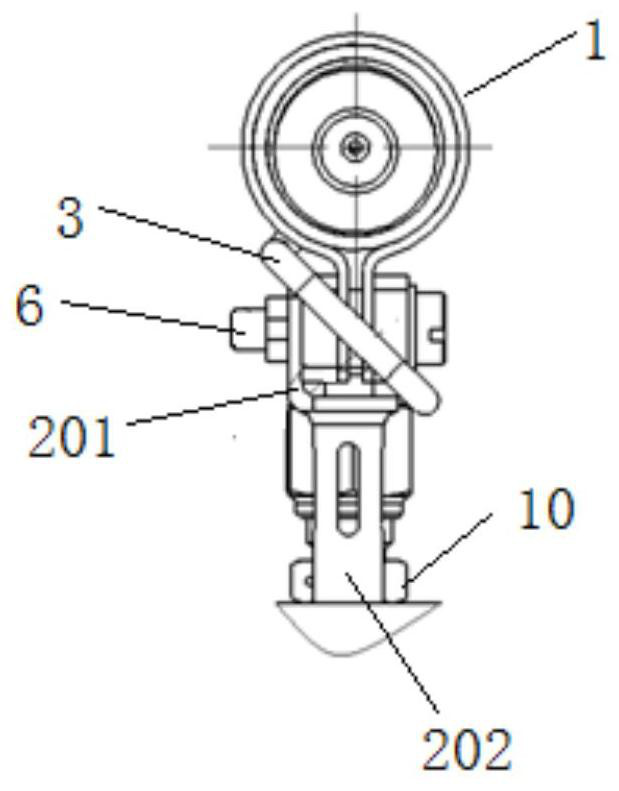

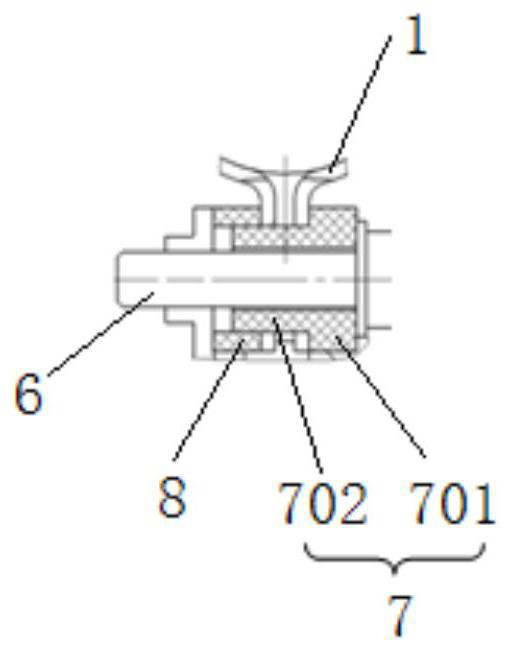

[0034] like Figures 1 to 7 A load cell narrow space heat shield mounting structure comprising a support base 2, pressure conduit 3 and two clamp 1. like Figure 4 with Figure 5 , The upper supporting base 2 is L-shaped fixing plate 201 for fixing the clamp 1, the lower part of the support base 202, support base 202 connected to the bottom end of the fixing plate 201, and the other end fixed to the wall surface of the combustion chamber 5, play a role in supporting and fixing. The clamp 1 may be the number of a plurality or greater than two, if a stability of the mounting structure may be reduced, by increasing the width of the clamp can be used as make up 1; 1 may be a plurality of clamp, fixing the support more reliable. Number and form a clamp can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com