Environment-friendly cable dehumidifying and drying equipment

A technology for drying equipment and cables, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of not saving labor, affecting the rotation of the fan blades, and having a lot of dust on the fan blades, achieving efficient, fast drying and dehumidification, and strong energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

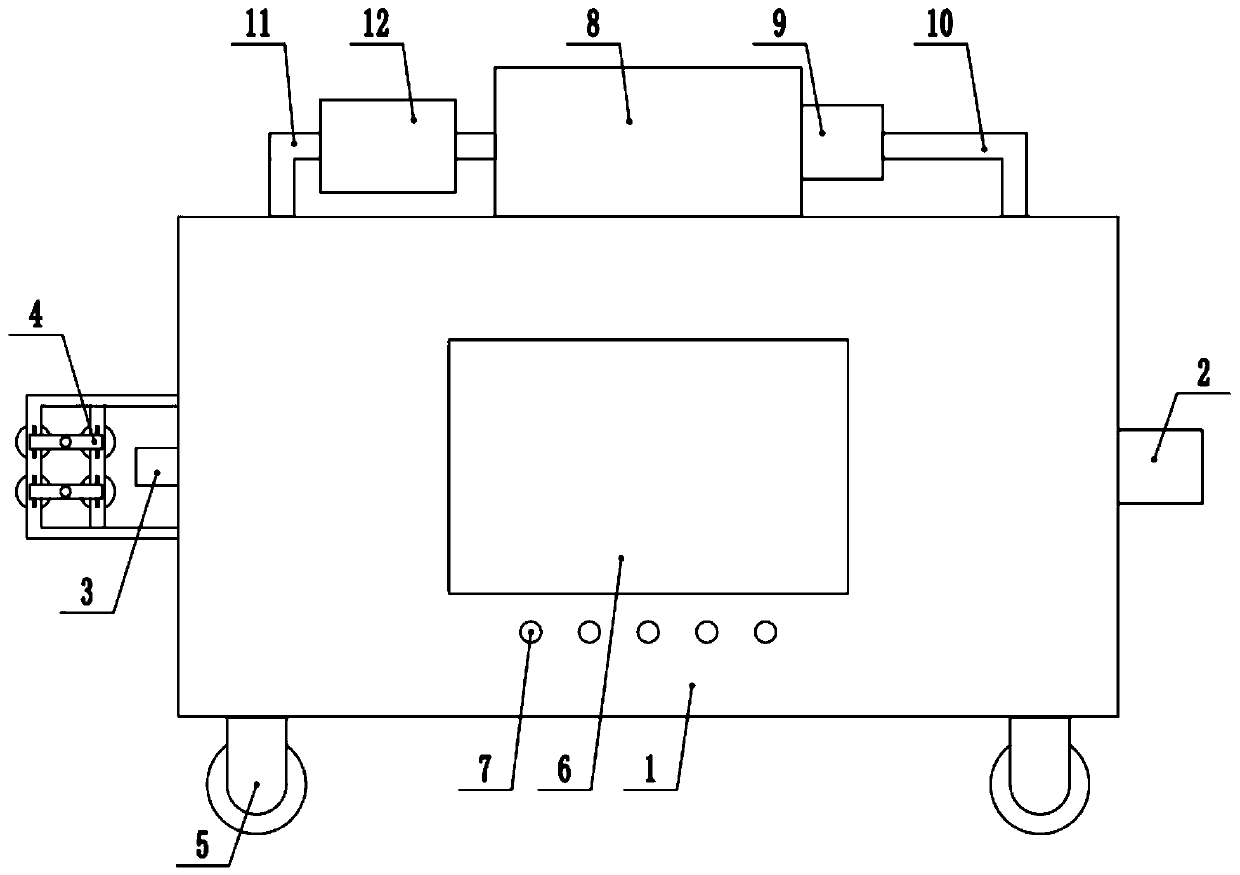

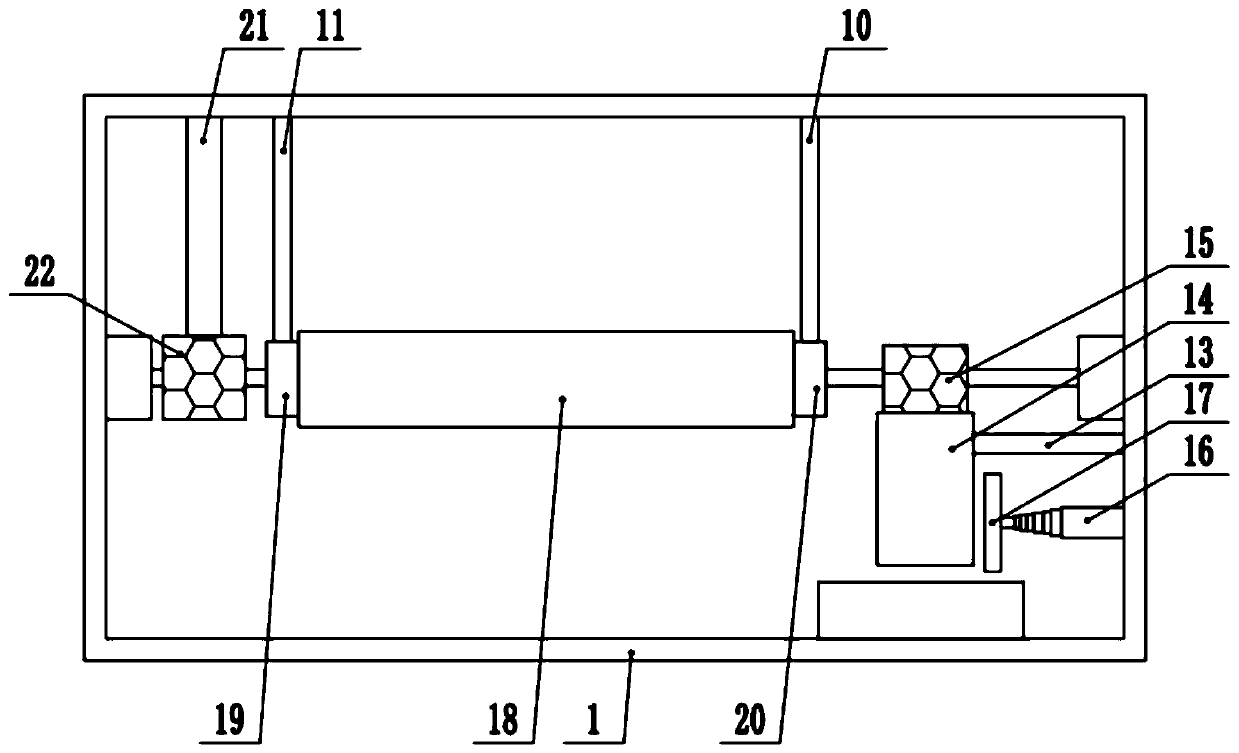

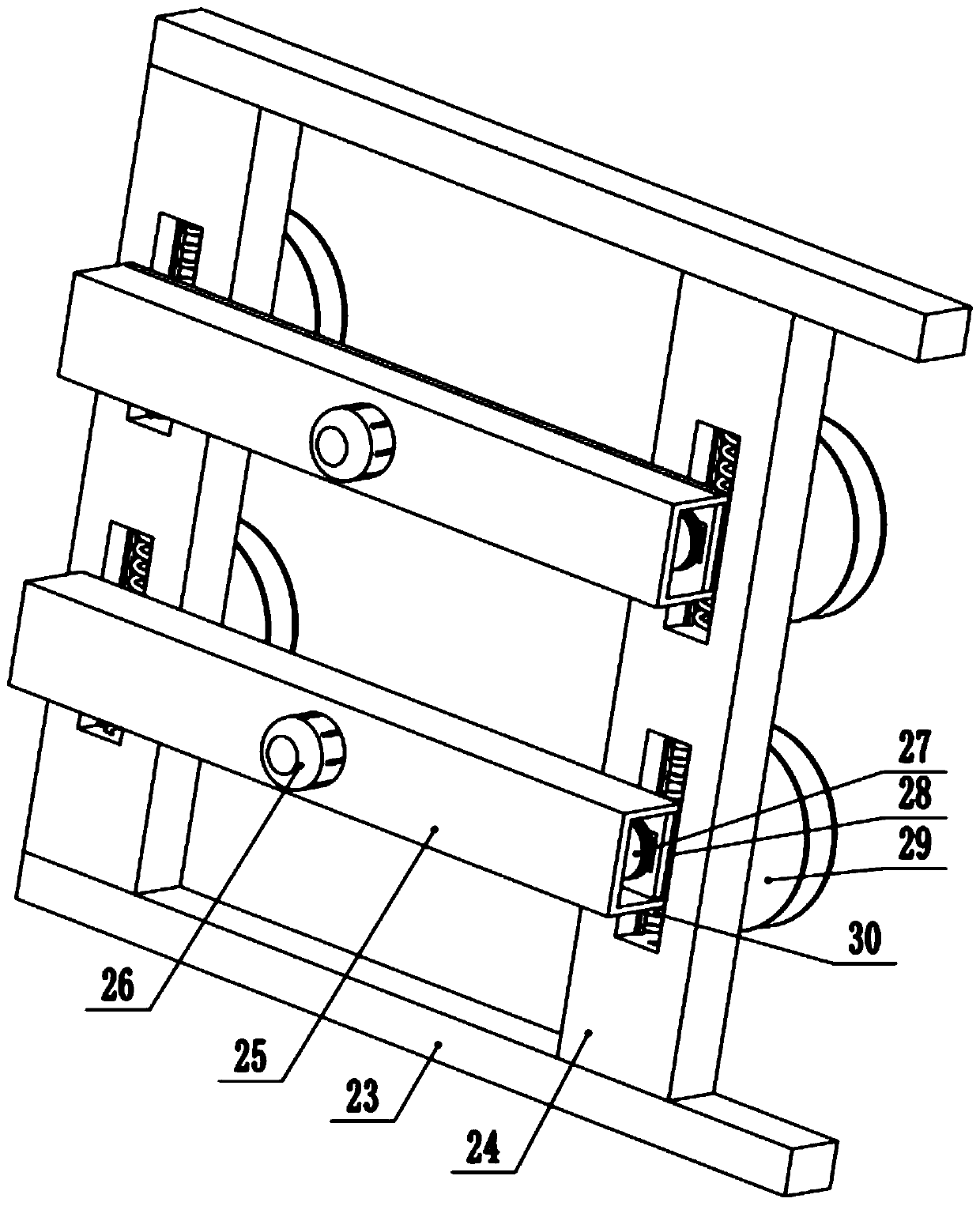

[0025] see Figure 1-3 , an environment-friendly cable dehumidification and drying equipment, including a dehumidification box 1, one end of the dehumidification box 1 is fixed with a conveying device 4, and the dehumidification box 1 is provided with a drying and dehumidification mechanism, and the drying and dehumidification mechanism includes a The hot air cover 18 in the middle part of the dehumidification box 1, the two ends of the hot air cover 18 are respectively fixedly connected to the air inlet cover 19 and the return air cover 20, and the tops of the air inlet cover 19 and the return air cover 20 are respectively fixedly connected to the exhaust pipe 11 and the return air Pipe 10, the top of the dehumidification box 1 is fixedly connected to the drying box 8, one end of the drying box 8 is fixedly connected to the blower 9, the input end of the blower 9 is fixedly connected to the return air pipe 10, and the exhaust pipe 11 passes through the dehumidification box 1 ...

Embodiment 2

[0029] see Figure 1-3 , including a dehumidification box 1, one end outside the dehumidification box 1 is fixedly provided with a conveying device 4, and a dry dehumidification mechanism is arranged inside the dehumidification box 1, and the dry dehumidification mechanism includes a hot air jacket 18 arranged in the middle of the dehumidification box 1 , the two ends of the hot air cover 18 are respectively fixedly connected to the air inlet cover 19 and the return air cover 20, and the tops of the air inlet cover 19 and the return air cover 20 are respectively fixedly connected to the exhaust pipe 11 and the return air pipe 10, the dehumidification box 1 The top is fixedly connected to the drying box 8, one end of the drying box 8 is fixedly connected to the blower 9, the input end of the blower 9 is fixedly connected to the return air pipe 10, and the exhaust pipe 11 passes through the dehumidification box 1 and is fixedly connected to the drying box 8. The exhaust pipe 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com