Automatic hydraulic augmented injection pump

A hydraulic automatic and motion technology, applied in the direction of pumps, piston pumps, machines/engines, etc., can solve the problems of not being able to discharge and increase injection at the same time, affecting the service life of the injection pump, and the incoming water pressure cannot be fine-tuned, etc., to achieve light weight , small size, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

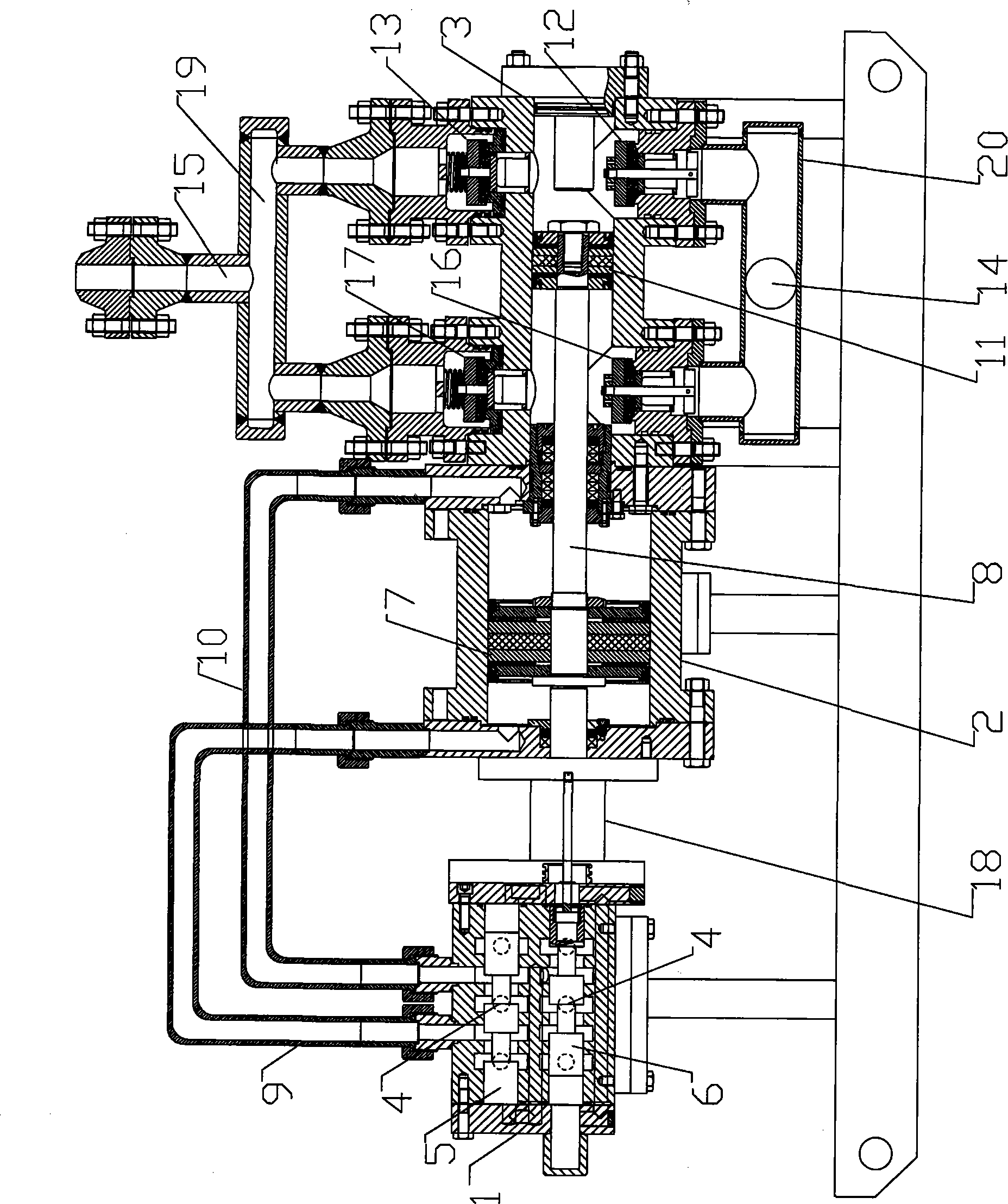

[0031] A hydraulic automatic injection pump, comprising a reversing valve 1, a power cylinder 2 and a booster cylinder 3, the valve chamber of the reversing valve 1 includes an upper chamber and a lower chamber, the upper chamber and the lower chamber are respectively provided with a water inlet 4, and the upper The chamber is provided with an upper chamber reversing valve core 5 moving in the upper chamber, and the lower chamber is provided with a lower chamber reversing valve core 6 moving in the lower chamber. The bonnet of the reversing valve 1 is provided with a front cover passage and The rear cover channel, the upper cavity and the lower cavity are communicated through the front cover channel and the rear cover channel respectively.

[0032] The power cylinder 2 is provided with a power piston 7 and a piston rod 8 that drives the power piston 7 to move. The first manifold 9 and the second manifold 10 communicate with the water outlet of the reversing valve 1 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com