A kind of ultra-long aluminum alloy beam low-pressure casting mold and casting method thereof

An aluminum alloy beam and low-pressure casting technology, applied in the field of aluminum alloy casting, can solve problems such as difficulty in product manufacturing, inability to adjust molds, product deformation, etc., achieve strong energy saving and environmental protection benefits, reduce weight and processing allowance, The effect of easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

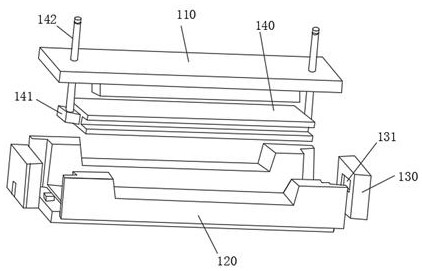

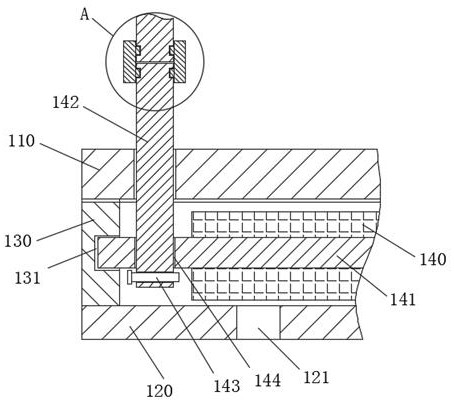

[0032] Embodiment 1 includes the following steps: Step 1. When the mold is closed, first close the two side molds 130 on both ends of the bottom mold 120, and engage the sand core 140 through the limit port 131, and then close the top mold 110 ;

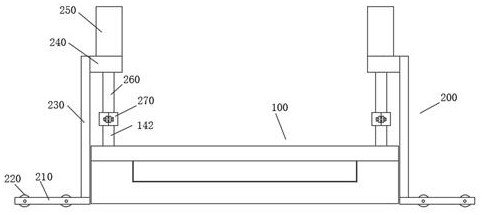

[0033] Step 2, connect the mold support, and fix the tie rod 142 with the piston rod 260 of the hydraulic cylinder 250 through the clamp sleeve 270;

[0034] Step 3, casting, connect the sprue 121 to the liquid outlet of the aluminum alloy liquid outlet equipment, slowly increase the pressure, the aluminum liquid enters the cavity of the mold body 100 through the sprue 121, and slowly increase the pressure so that the aluminum liquid passes through the internal sprue slowly Fill the cavity, then quickly increase the pressure, and release the pressure after maintaining the pressure and cooling for a period of time;

[0035] Step 4: Open the mold, start the hydraulic cylinder 250, and lift the top mold 110 to a suitable height by shri...

Embodiment 2

[0038] Embodiment 2 includes the following steps: Step 1. When the mold is closed, first close the two side molds 130 on both ends of the bottom mold 120, and engage the sand core 140 through the limit port 131, and then close the top mold 110 ;

[0039] Step 2, connect the mold support, and fix the tie rod 142 with the piston rod 260 of the hydraulic cylinder 250 through the clamp sleeve 270;

[0040] Step 3, casting, connect the sprue 121 to the liquid outlet of the aluminum alloy liquid outlet equipment, slowly increase the pressure, the aluminum liquid enters the cavity of the mold body 100 through the sprue 121, and slowly increase the pressure so that the aluminum liquid passes through the internal sprue slowly Fill the cavity, then quickly increase the pressure, and release the pressure after holding and cooling for a period of time;

[0041] Step 4: Open the mold, start the hydraulic cylinder 250, and lift the top mold 110 to a suitable height by shrinking the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com