Fire extinguishing agent releasing method and non-stored-pressure fire extinguishing device

A fire extinguishing device and fire extinguishing agent technology, applied in the field of fire extinguishing agent release method and non-storage pressure fire extinguishing device, can solve the problems of bulky, small fire extinguishing range, high cost, etc., to improve fire extinguishing efficiency, reduce production cost, and low processing requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

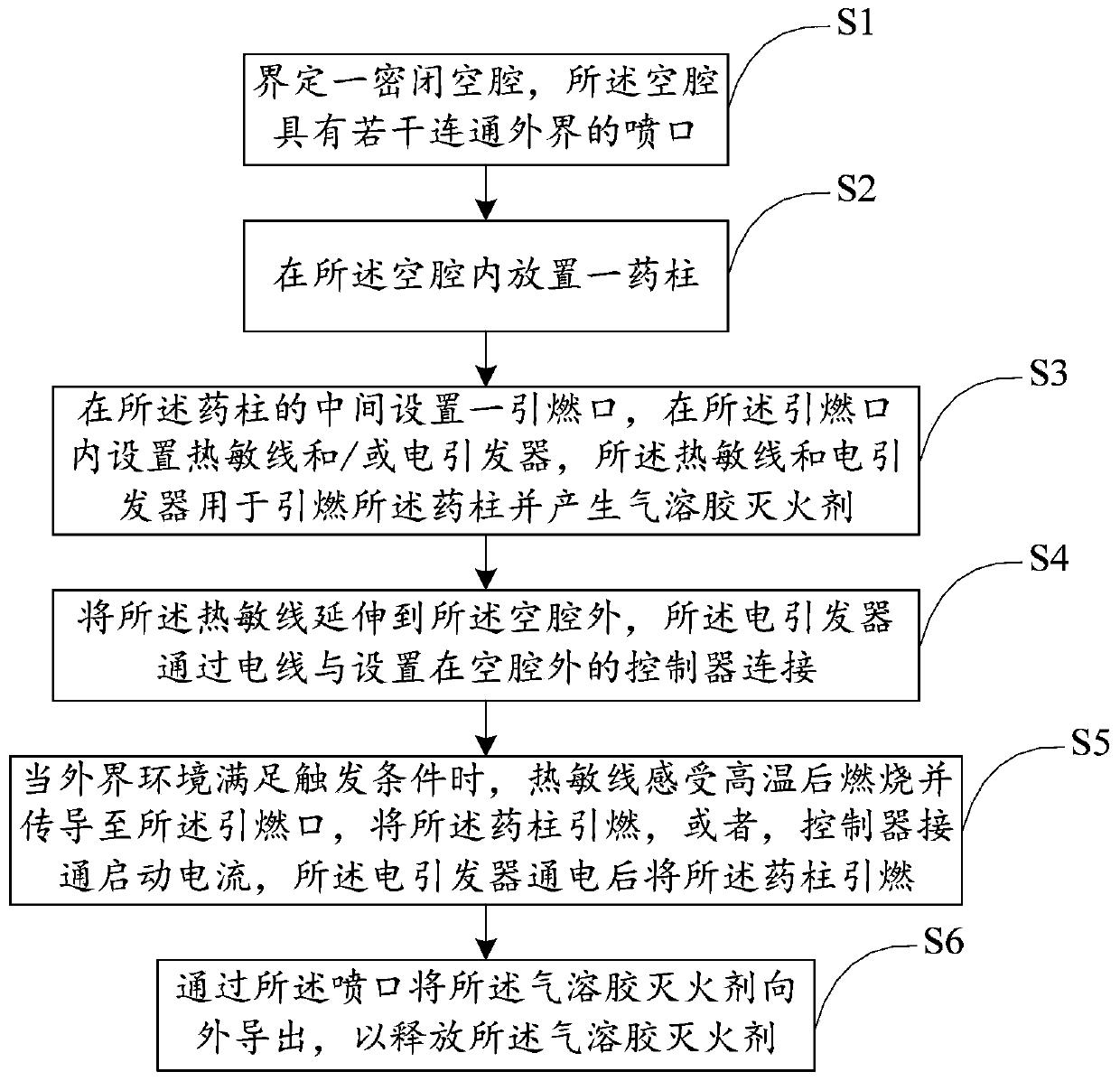

[0032] Such as figure 1 As shown, this embodiment provides a fire extinguishing agent release method for spraying the fire extinguishing agent outward when the trigger condition is met. The method mainly includes the following steps:

[0033] S1: define a closed cavity, the cavity has a number of spouts connected to the outside world;

[0034] S2: placing a grain in the cavity;

[0035] S3: An ignition port is provided in the middle of the grain, and a thermosensitive line and / or an electric initiator is arranged in the ignition port, and the thermosensitive line and the electric initiator are used to ignite the grain and generate Aerosol fire extinguishing agent;

[0036] S4: extending the thermal wire to the outside of the cavity, and the electric trigger is connected to a controller arranged outside the cavity through a wire;

[0037] S5: When the external environment satisfies the triggering conditions, the heat-sensitive wire will burn after feeling the high temperatur...

Embodiment 2

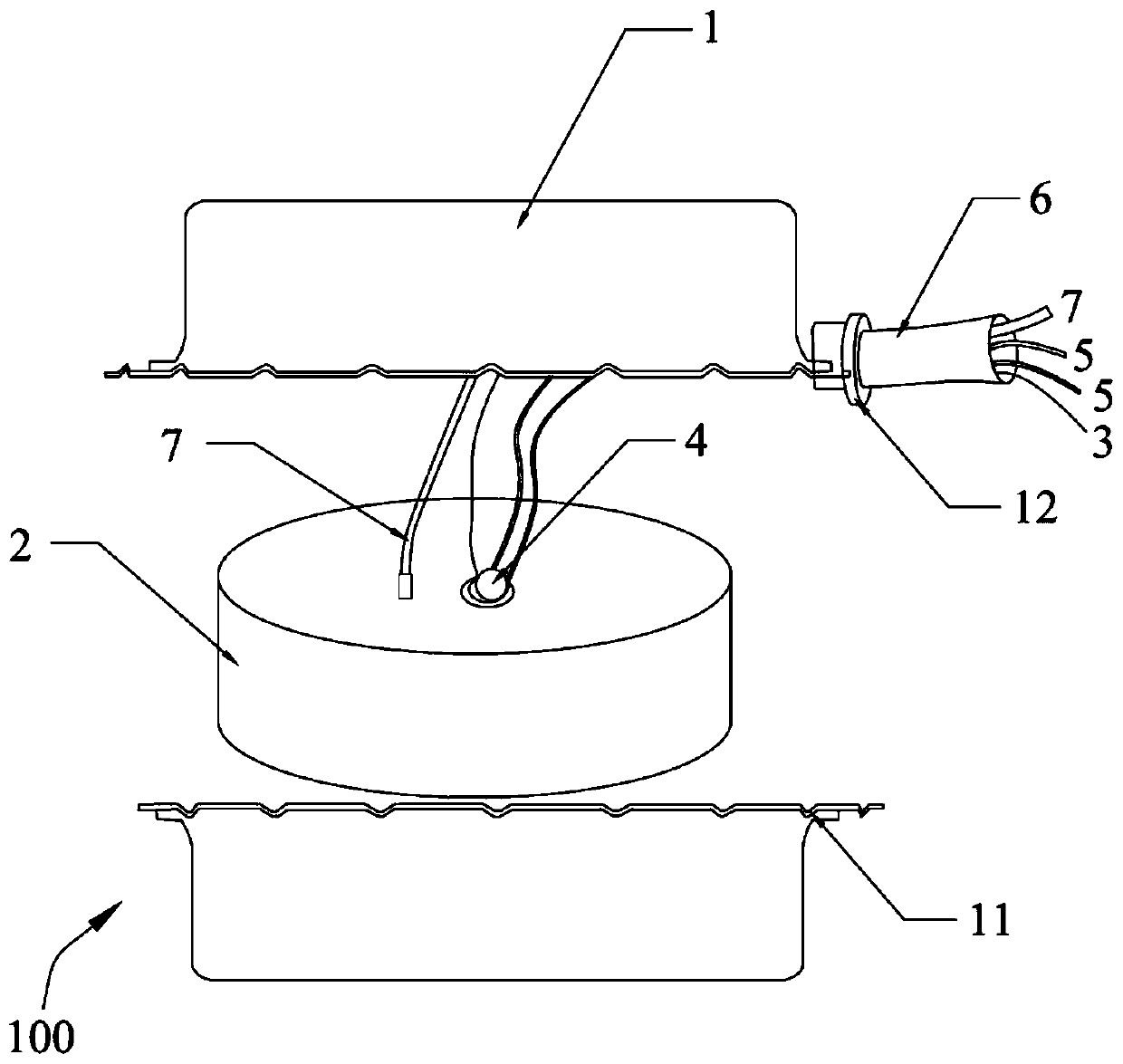

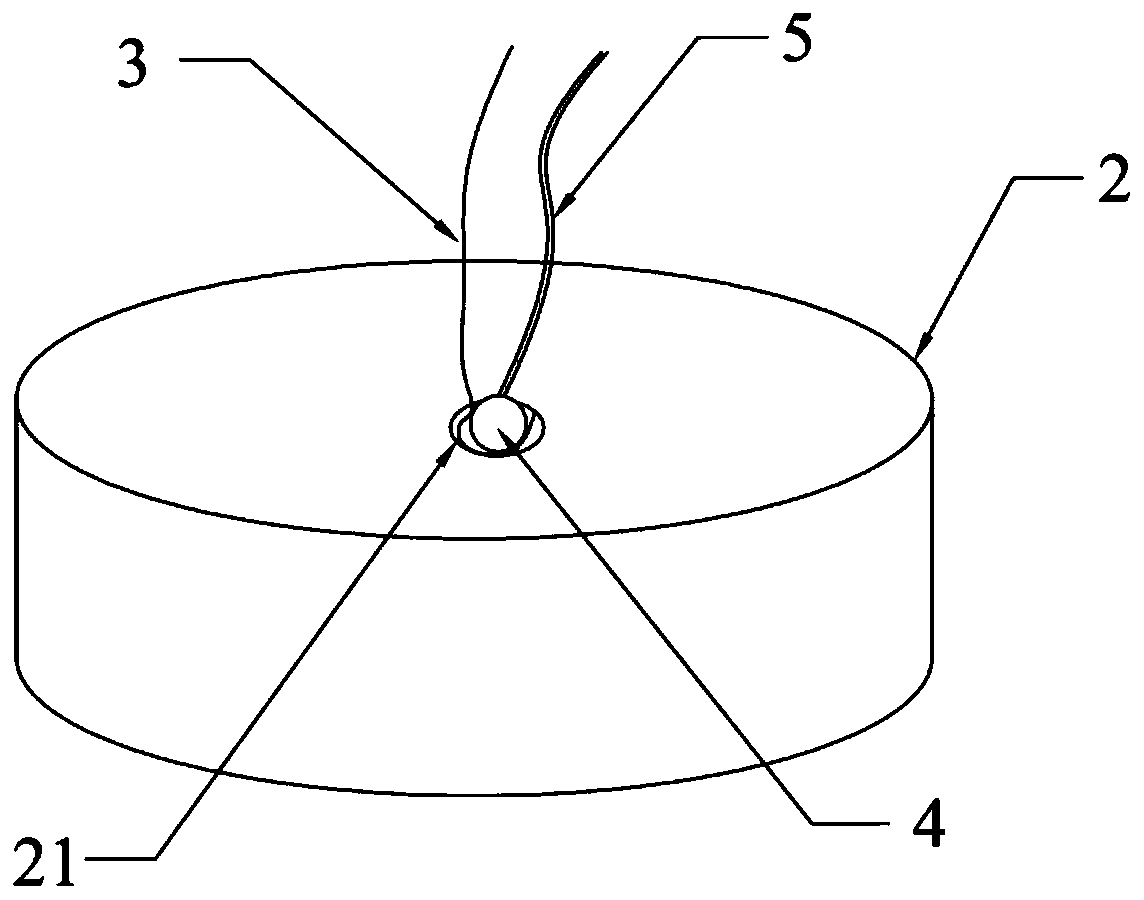

[0050] refer to figure 2 and image 3 As shown, this embodiment provides a non-storage pressure fire extinguishing device 100, including a closed tank body 1, a powder column 2 arranged in the tank body 1, and a thermal sensor for igniting the powder column 2 to generate a fire extinguishing agent. Wire 3 and Electric Initiator 4. There is an ignition port 21 in the middle of the powder column 2, and the thermal sensitive wire 3 and the electric initiator 4 are located in the ignition port 21. The thermosensitive line 3 extends out of the tank body 1 , and when the heated temperature reaches a certain value (for example, 170° C.), it can spontaneously ignite and quickly conduct along the line to the ignition port 21 to ignite the powder column 1 . The electric initiator 4 is connected to a controller (not shown) arranged outside the tank body 1 through an electric wire 5, and when the current output from the controller to the electric initiator 4 reaches a predetermined val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com