Breaking head structure for cement silo cleaning

A crushing head and cement technology, which is applied in the field of cement cleaning and crushing equipment, can solve the problems of unsatisfactory crushing effect, inconvenient replacement of crushing saw blades, and low crushing efficiency, so as to increase the utilization rate of equipment, facilitate installation and disassembly, and reduce maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

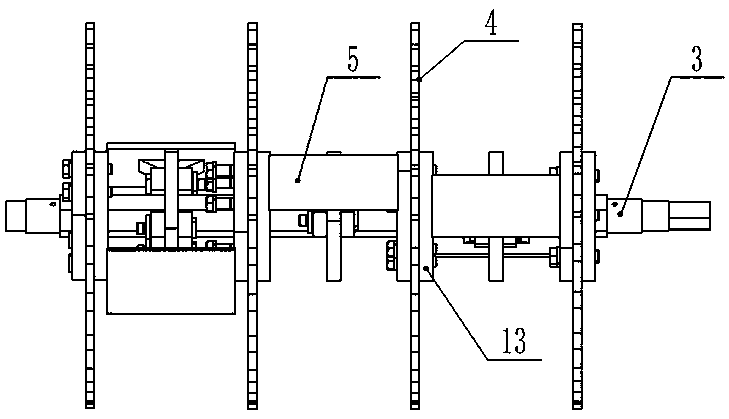

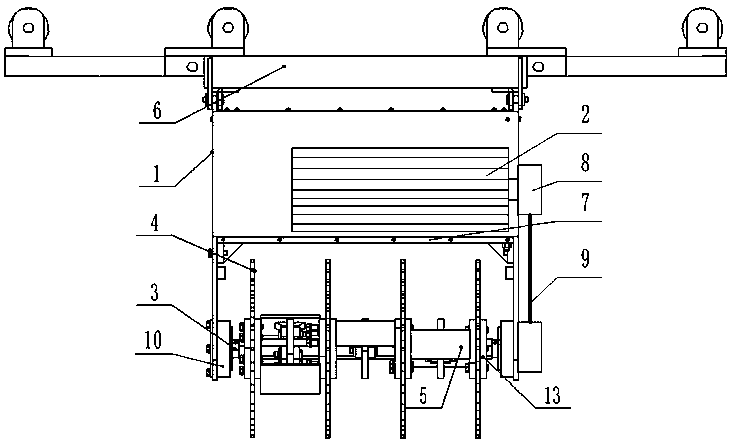

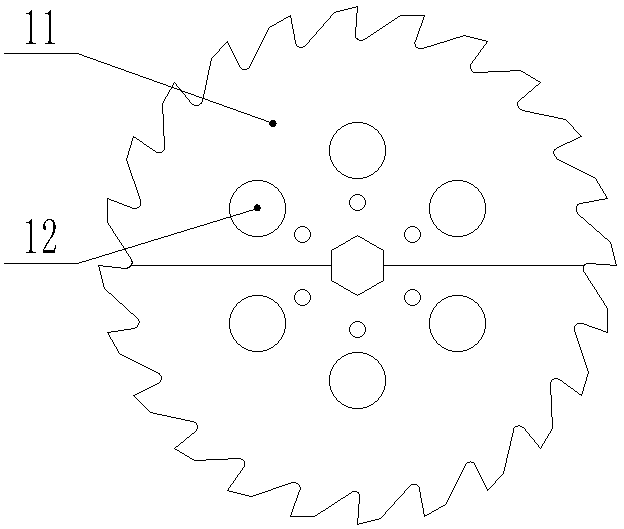

[0026] Such as Figure 1-4 As shown, the structure of a crushing head for cement clearing in the present invention includes a crusher shaft 3, a cutting saw blade 4 and a crushing hammer head 5, and a plurality of cutting saw blades 4 are fixed on the crusher shaft 3. This implementation Four saw blades are selected, and a plurality of crushing hammer heads 5 are arranged around the crusher rotating shaft 3 between two adjacent cutting saw blades 4, which are three sets of crushing hammer head devices. A set of crushing hammer head devices generally includes two crushing hammer head devices. One or three broken hammer heads 5; each cutting saw blade 4 is a combination of two semicircular structure saw blades 11, and a mounting hole 12 is provided on the semicircular structure saw blade 11, and the mounting hole 12 is used for placing bolts. It will be used in conjunction with the splint 13 later.

[0027] The cutting saw blade is a vulnerable part of the crushing device of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com