Wheel replacing and adjusting method for large crane

An adjustment method and crane technology, which are applied to cranes, traveling mechanisms, load suspending elements, etc., can solve problems such as the influence of the life of wheels and rails, increase costs, and gnaw the rails of wheels, so as to avoid long-term downtime accidents and prolong service life. Longevity, guarantee the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention can quickly replace the wheel without re-adjusting the horizontal combination form of the wheel, can ensure that the wheel reaches the original installation size, and prolong the service life of the wheel.

[0027] The present invention adopts the following steps:

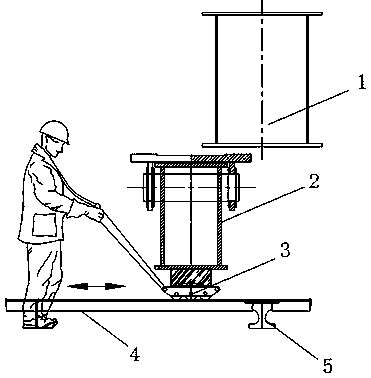

[0028] The first step is to disassemble the balance trolley.

[0029] a. Detect the horizontal combination form and horizontal deviation value of the original sets of wheels on one side to provide the original basis for replacing the balance beam on the other side;

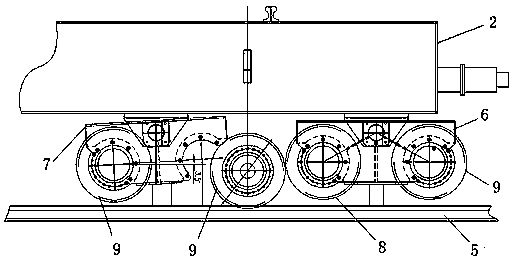

[0030] b. Disassemble the connecting bolts of several groups of balance beams 2 at the same time, and disassemble the connecting bolts of the two driving wheel 8 couplings at the same time. Each group of balance beams has 8 groups of fixing bolts. After all are loosened, only 6 groups are removed, inside and outside. 1 set for each;

[0031] c. Start to lift the balance beam with a hydraulic jack, and stop when the bottom surface of all whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com