A recyclable centering system for steel cages and construction method thereof

A construction method and steel cage technology, applied in infrastructure engineering, caissons, buildings, etc., can solve problems such as poor ability to respond to changes, complex construction operations, and low fineness, and achieve high alignment fineness and simple connection relationships , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

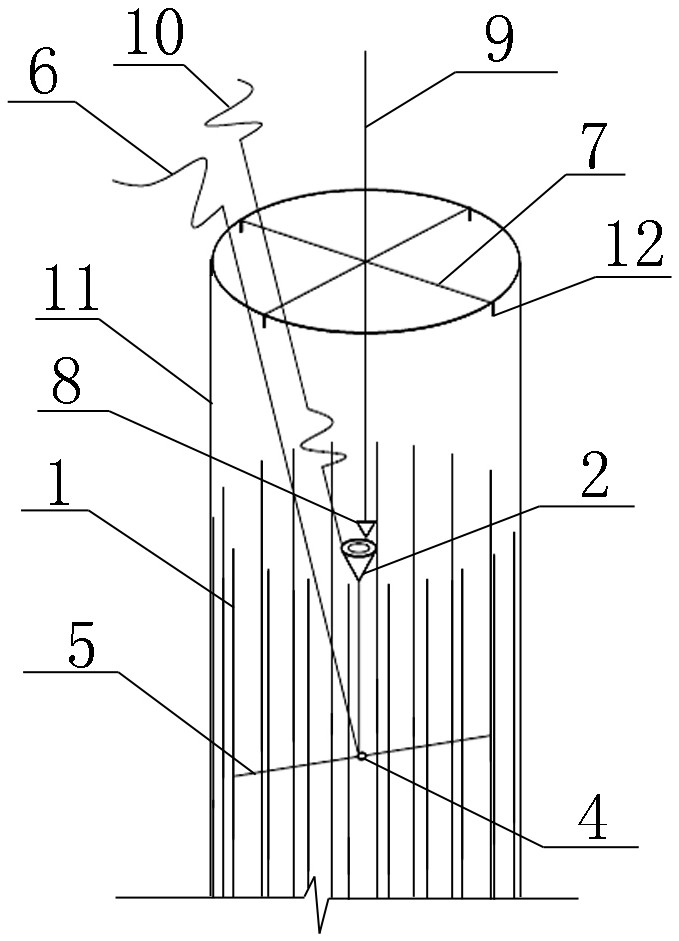

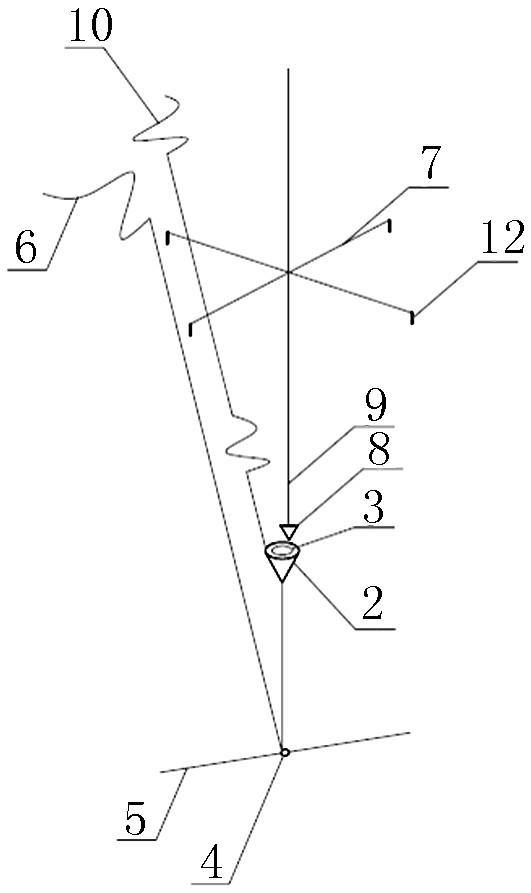

[0031] Such as Figure 1-3 As shown, the centering system of this recyclable reinforcement cage is used to locate the reinforcement cage 1 in the pile foundation; it includes a buoy 2, a buoy positioning device and a reinforcement cage positioning device; the top surface of the buoy 2 The middle part is provided with a positioning ring 3; the buoy positioning device is arranged below the buoy 2, including a positioning ring 4, a positioning rope 5 and a buoy control rope 6; the positioning ring 4 is arranged in the reinforcement cage 1 to be positioned, and The center of the locating ring 4 coincides with the central axis of the reinforcing cage 1; the locating rope 5 has at least two, which are connected to the locating ring 4 at intervals, and the locating rope 5 binds the locating ring 4 and the reinforcing cage 1; the buoy One end of the control rope 6 is connected to the center of the bottom of the buoy 2, and the other end of the buoy control rope 6 passes through the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com