A fan blade structure for an oven

A technology of fan blades and ovens, applied in the field of ovens, can solve the problems of spatial streamline disorder, temperature uniformity not as good as forward rotation temperature uniformity, fan blades not suitable for forward and reverse rotation needs, etc., to achieve consistent flow field streamlines , the effect of keeping the air volume consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

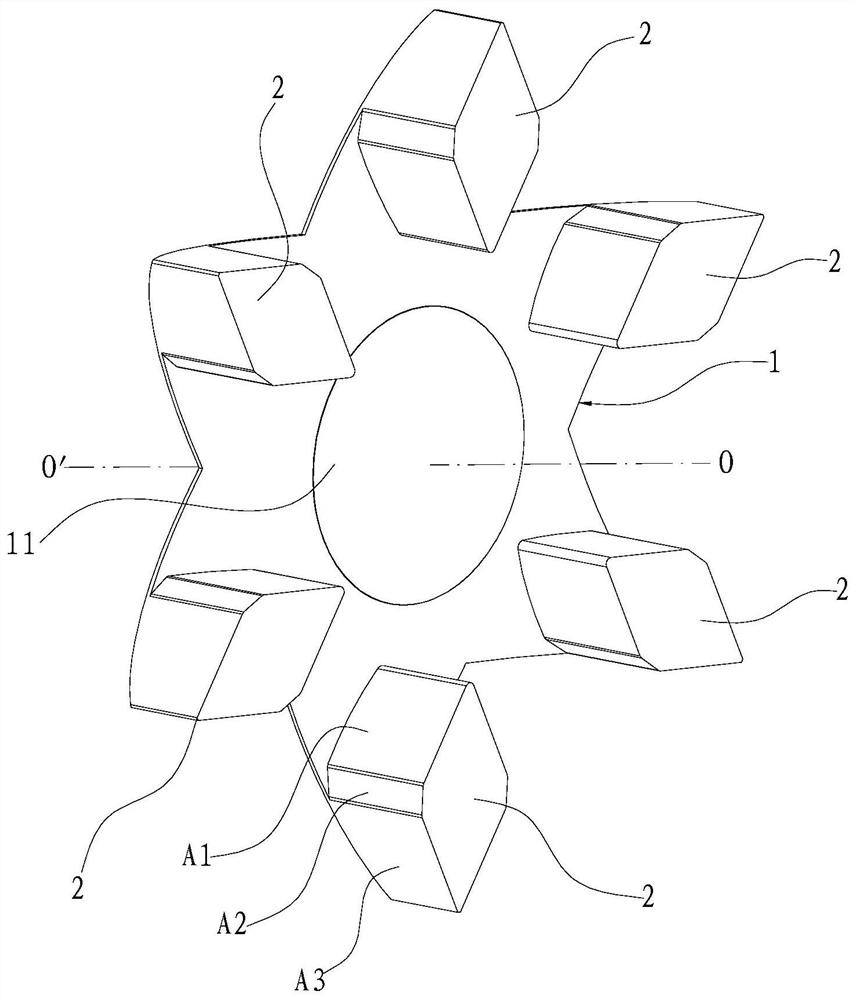

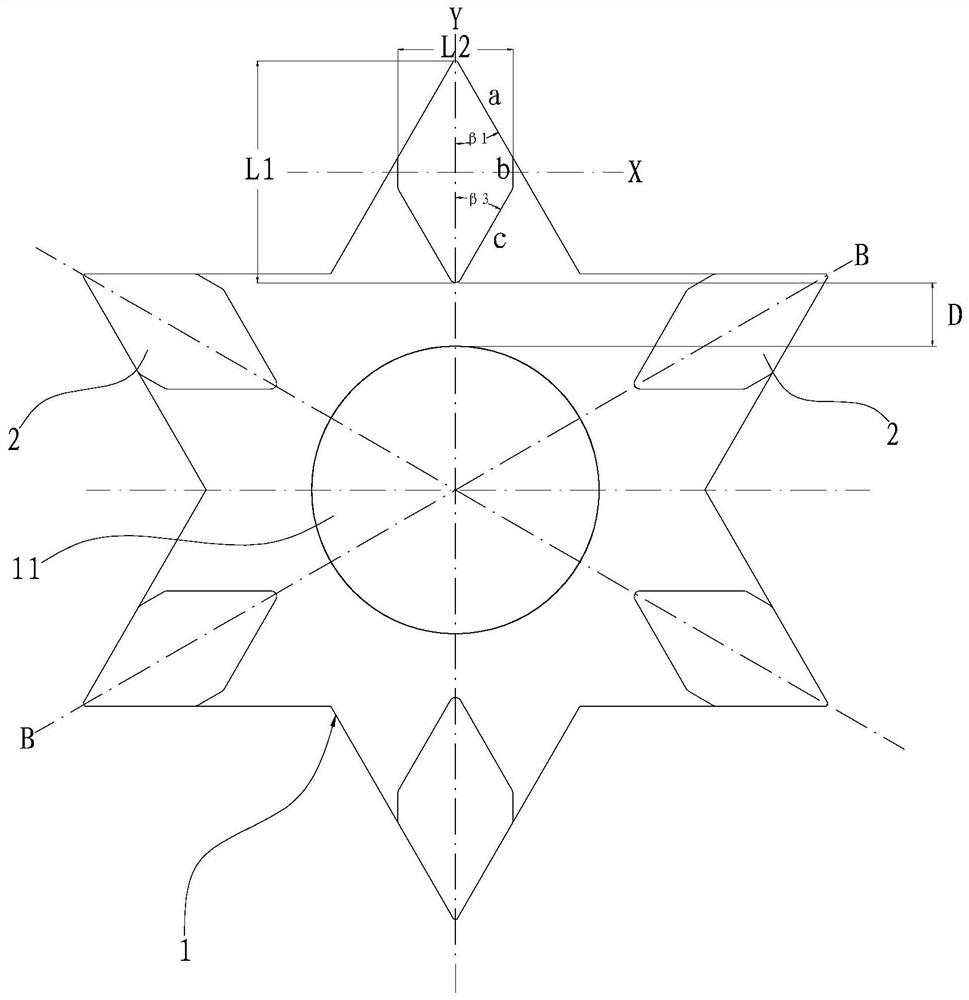

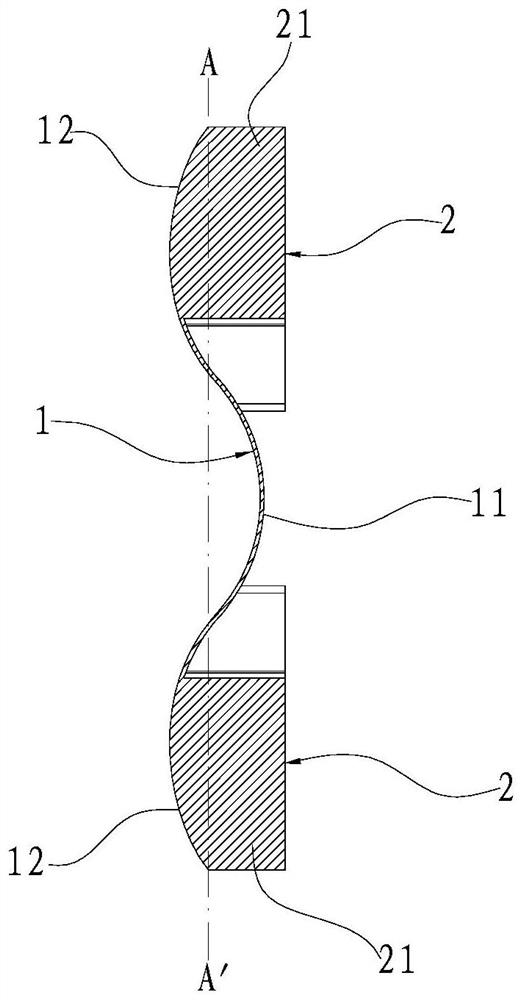

[0032] Such as Figure 1~4 As shown, a fan blade structure for an oven includes a support plate 1 and guide vanes 2 arranged on the support plate 1 . In this embodiment, the shape of any transverse section of the above-mentioned support plate 1 is centrally symmetrical, and the above-mentioned guide vanes 2 are evenly distributed on the surface of the support plate 1 at intervals in the circumferential direction around the central axis OO' of the support plate 1, The outermost end of each guide vane 2 all overlaps with the outermost end of the support plate 1 plate surface where it is located, and each guide vane 2 is arranged along the radial direction of the support plate 1 plate surface where it is located, and each guide vane 2 Any transverse section has a first axis of symmetry Y extending radially along the surface of the support plate 1 where it is located.

[0033] In this embodiment, when the fan blade structure is placed horizontally, the horizontal projection of th...

Embodiment 2

[0041] Such as Figure 5 As shown, the difference from the embodiment is that in this embodiment, the size of each sharp angle of the horizontal projection of the support plate 2 is 90°, and each guide vane 2 is located at the outermost surface of the support plate 1 where it is located. The part 21 above the transverse section AA' of the support plate 1 where the end is located, any transverse section of this part 21 is square as a whole, and β 1 and beta 3 are 45 degrees, and β 2 is 0 degrees.

Embodiment 3

[0043] Such as Figure 6 and 7 As shown, the difference from Embodiment 1 is that the shape of each guide vane 2 in this embodiment is plate-shaped. At this time, from the above formula, the entire outer surface of the guide vane 2 is the effective windward area, and the positive and negative Maximum air flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com