Heat exchanger for air conditioning system

A technology for heat exchangers and air-conditioning systems, applied in the field of operating the heat exchangers and motor vehicles, can solve problems such as uneven heating of air, and achieve the effects of small installation space, simple technical methods, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

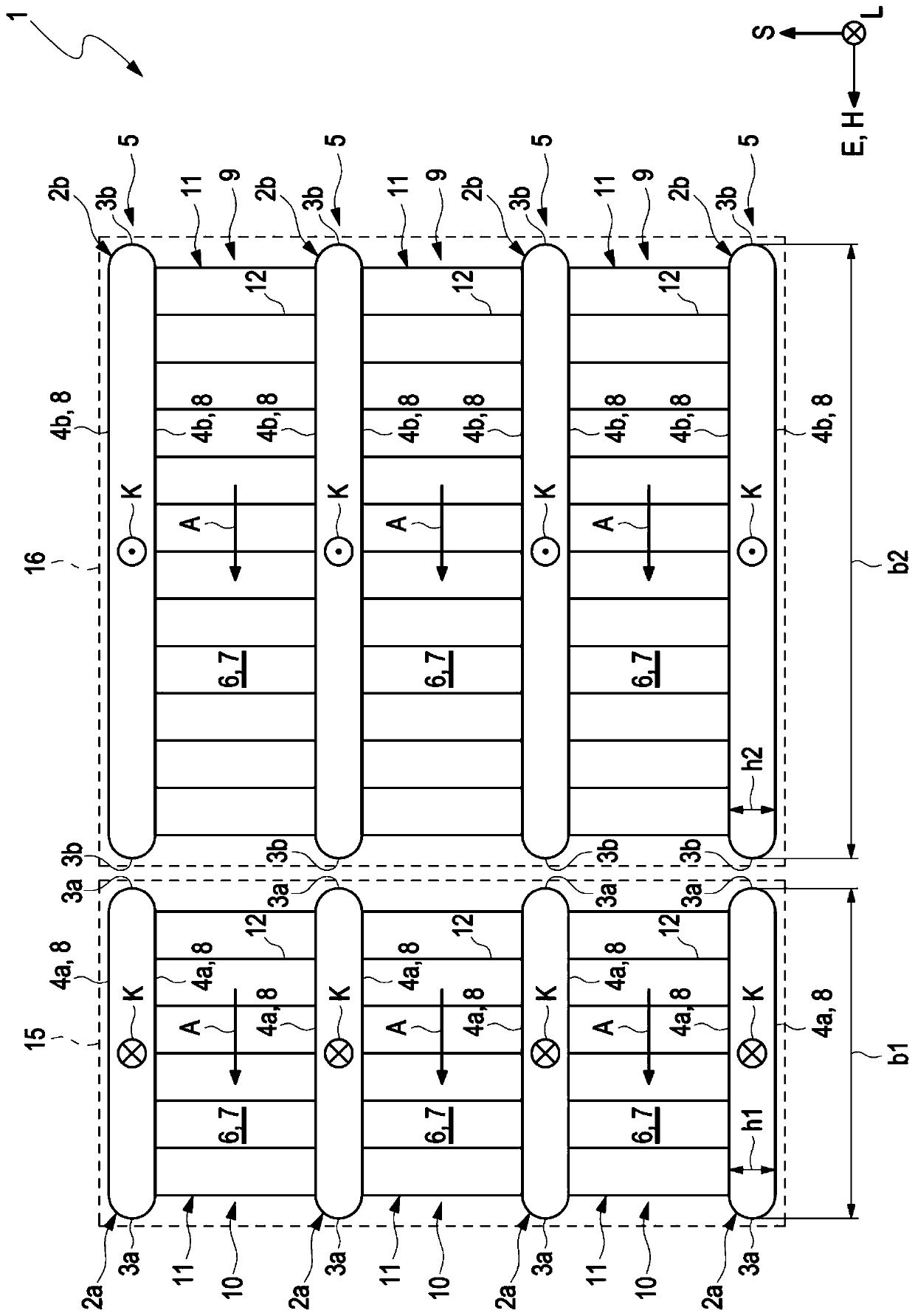

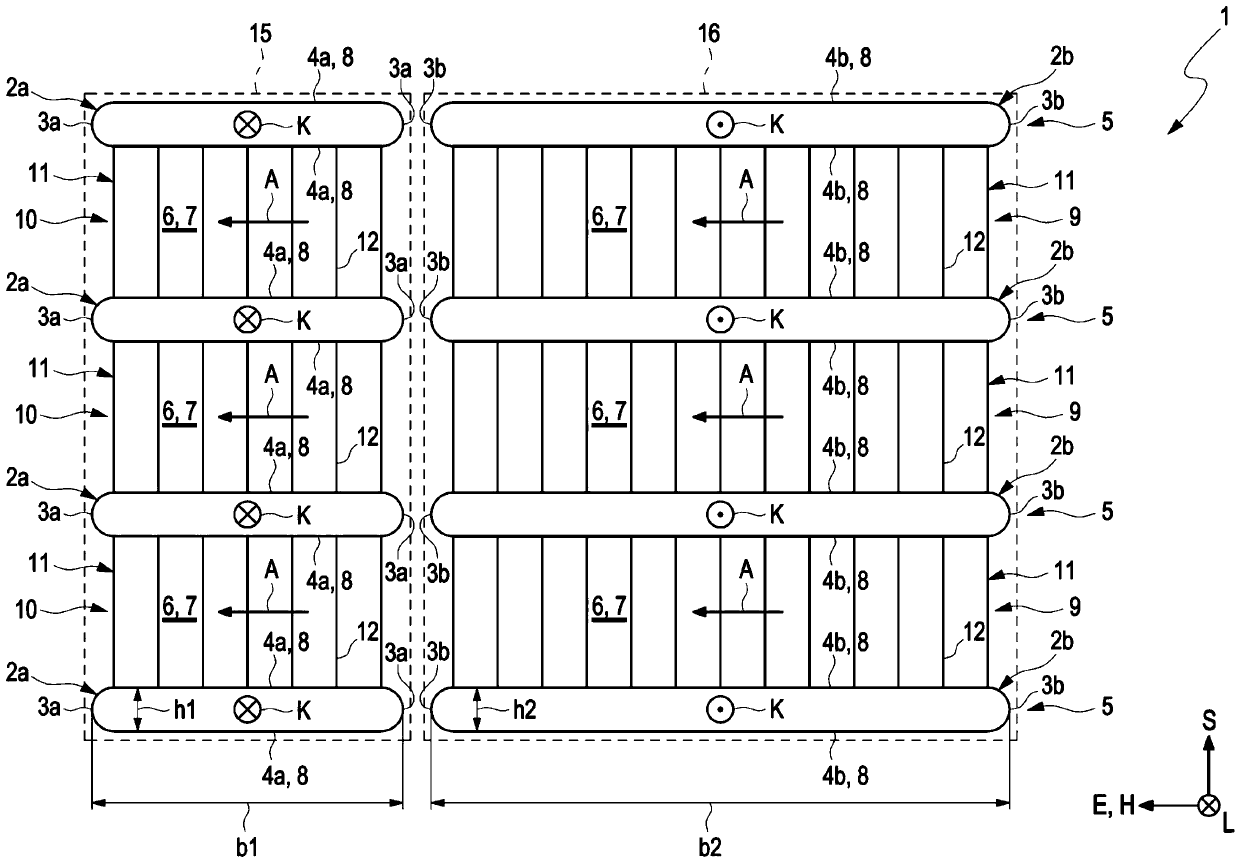

[0028] according to figure 1 , the heat exchanger 1 comprises a plurality of first flat tubes 2a, which are stacked on top of each other along the stacking direction S and thus arranged at a distance from each other and which each extend along a longitudinal direction L, the longitudinal direction L The direction L extends perpendicularly to the stacking direction S. The first flat tube 2 a is configured for the refrigerant K to flow therethrough.

[0029] In a cross-section perpendicular to the longitudinal direction L—this cross-section is in figure 1 As explained in , the first flat tubes each have two narrow sides 3a and two broad sides 4a. The heat exchanger 1 further comprises a plurality of second flat tubes 2b which are stacked on top of each other in the same manner as the first flat tubes 2a along the stacking direction S and are arranged at a distance from one another and also along The longitudinal direction L extends and is configured for refrigerant K to flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com