Determination method of firing process performance of cement rotary kiln based on fractional lqg benchmark

A technology of cement rotary kiln and determination method, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve the problems of control system control accuracy decline, controller performance decline, resource waste, etc. The effect of low energy consumption control and good input performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Take the firing process of cement rotary kiln as an example:

[0047] In the cement production process, the cement rotary kiln firing process is an important part of cement production. After the cement raw meal is prepared, the cement raw meal continues to enter the cement rotary kiln. At this time, the coal injection kiln head of the rotary kiln starts to inject coal into the rotary kiln. The rotary kiln is heated, and the cement clinker reacts. Rising to a certain level, the cement raw meal is gradually transformed into cement clinker.

[0048] Step 1. Establish the fractional order model of the controlled object in the cement rotary kiln firing process. The specific steps are:

[0049] 1-1. First collect the real-time operation data of the cement rotary kiln firing process, and establish the fractional-order discrete-time model of the cement rotary kiln firing process under uncertain disturbance in the following form:

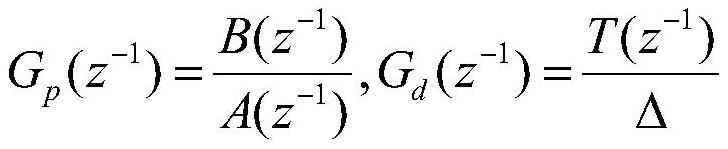

[0050] Y k =G p (z -1 )U k +G d (z -1 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com