Zinc oxide volatilization kiln hybrid modeling method based on mechanism and support vector machine

A technology of support vector machine and mechanism modeling, which is applied in the field of hybrid modeling of zinc oxide volatilization kilns, can solve the problems of few variables and production factors, and cannot reflect the chemical reaction process and production mechanism of materials in the volatilization kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

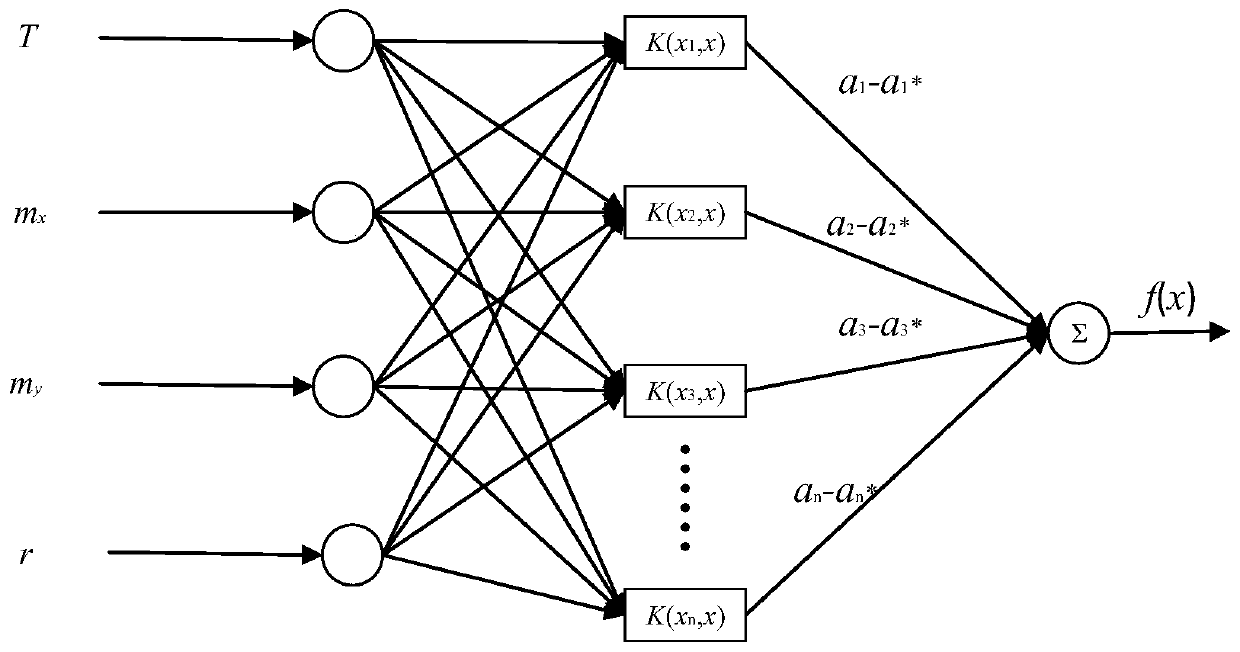

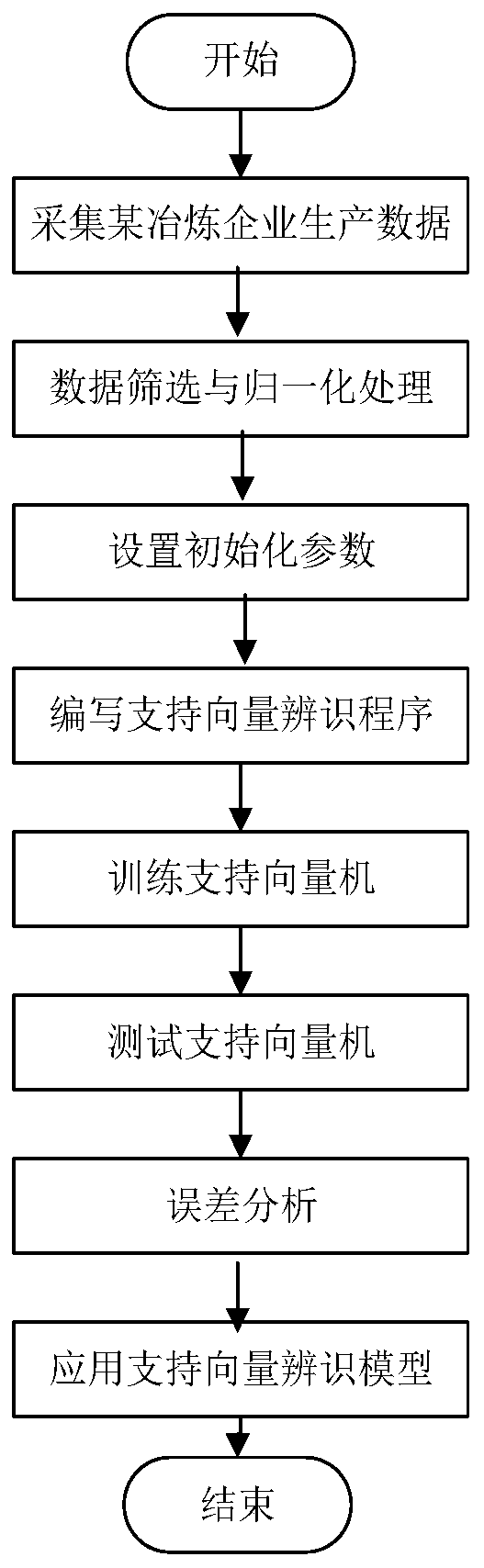

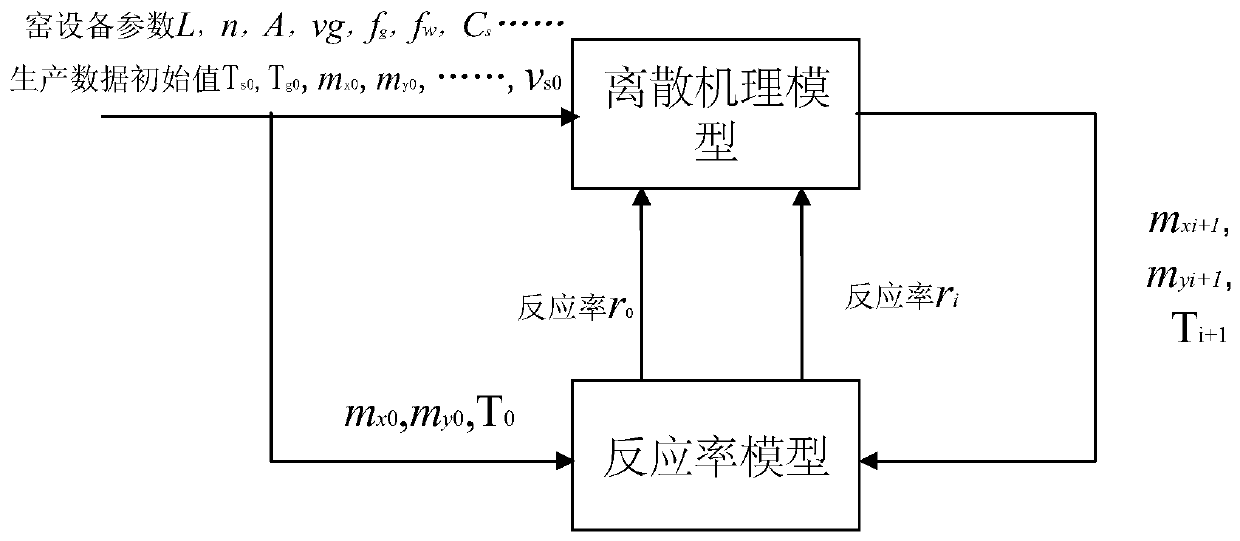

[0053] According to the production characteristics of the zinc oxide volatilization kiln and the problem that the existing volatilization kiln modeling method is difficult to accurately characterize the production conditions and reaction mechanism of the kiln object, the present invention proposes a mixed modeling method for the zinc oxide volatilization kiln. Through in-depth research on the structure, production process, internal physical and chemical reaction process and heat and mass transfer mechanism of the zinc oxide volatilization kiln, the chemical reaction equation in the zinc oxide volatilization kiln was obtained, and according to the thermodynamics and the obtained on-site production data, the formula The activation energy and heat absorption and heat release of each reaction equation, according to the conservation law, the partial differential equations of the quality and energy of the zinc oxide volatilization kiln with respect to the kiln length and time are esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com