A hydrothermal lithium supplementation-spray remodeling regeneration method for waste ternary cathode materials

A technology for positive electrode materials and ternary lithium batteries, which is applied in the direction of electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of long process flow of ternary positive electrode materials, increase the difficulty of waste liquid treatment, and complicated process flow, and achieve good results. Electrochemical performance, realization of direct regeneration and high-value utilization, and simple operation of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

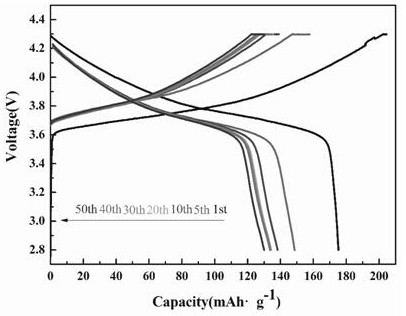

Embodiment 1

[0035] A hydrothermal lithium supplementation-spray remodeling regeneration method for waste ternary positive electrode materials, the specific steps are as follows:

[0036] (1) Replace the waste NCM622 (LiNi 0.6 co 0.2 mn 0.22 o 2 ) The ternary lithium battery is placed in a sodium chloride solution with a concentration of 2mol / L, placed for 36 hours, deeply discharged, and the battery is manually disassembled to separate the positive aluminum foil, negative copper foil, shell, diaphragm, tabs, etc.;

[0037] (2) Put the positive electrode aluminum foil in a sodium hydroxide solution with a concentration of 1mol / L, then peel off the positive electrode material, and wash the peeled positive electrode material with a sodium hydroxide solution with a concentration of 1mol / L;

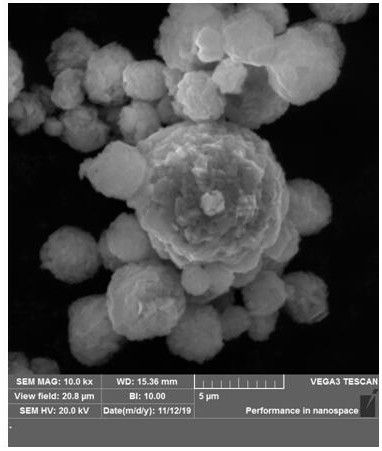

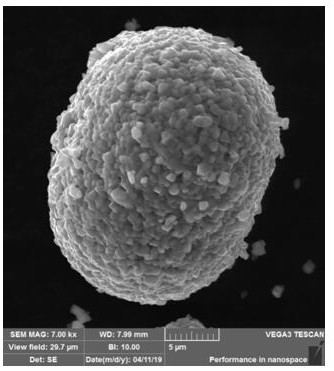

[0038] (3) Put the waste ternary lithium battery positive electrode material obtained in step (2) into a drying oven at 120°C and dry for 12 hours; then put it into a box furnace for calcination at 650...

Embodiment 2

[0047] A hydrothermal lithium supplementation-spray remodeling regeneration method for waste ternary positive electrode materials, the specific steps are as follows:

[0048] (1) Replace the used NCM523 (LiNi 0.5 co 0.2 mn 0.3 o 2 ) The ternary lithium battery is placed in a sodium chloride solution with a concentration of 2mol / L, placed for 36 hours, deeply discharged, and the battery is manually disassembled to separate the positive aluminum foil, negative copper foil, shell, diaphragm, tabs, etc.;

[0049] (2) Put the positive electrode aluminum foil in a sodium hydroxide solution with a concentration of 2mol / L, then peel off the positive electrode material, and wash the peeled positive electrode material with a sodium hydroxide solution with a concentration of 2mol / L;

[0050] (3) Put the waste ternary lithium battery positive electrode material obtained in step (2) into a drying oven at 150°C and dry for 10 hours; then put it into a box furnace for calcination at 600°C...

Embodiment 3

[0059] A hydrothermal lithium supplementation-spray remodeling regeneration technology for waste ternary cathode materials, the specific steps are as follows:

[0060] (1) Replace the used NCM811 (LiNi 0.8 co 0.1 mn 0.1 o 2 ) The ternary lithium battery is placed in a sodium chloride solution with a concentration of 2mol / L, placed for 36 hours, deeply discharged, and the battery is manually disassembled to separate the positive aluminum foil, negative copper foil, shell, diaphragm, tabs, etc.;

[0061] (2) Put the positive electrode aluminum foil in a sodium hydroxide solution with a concentration of 1.5mol / L, then peel off the positive electrode material, and wash the peeled positive electrode material with a sodium hydroxide solution with a concentration of 1.5mol / L;

[0062] (3) Put the waste ternary lithium battery positive electrode material obtained in step (2) into a drying oven at 135°C and dry for 16 hours; then put it into a box furnace for calcination at 700°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com