Skeleton parts for automobiles

A component and skeleton technology, applied in the field of automobile skeleton parts, can solve problems such as difficult repair, light weight, low rigidity of foamed resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Since an experiment was conducted to verify the effect of improving the rigidity and reducing the weight of the automobile frame member according to the present invention, it will be described below.

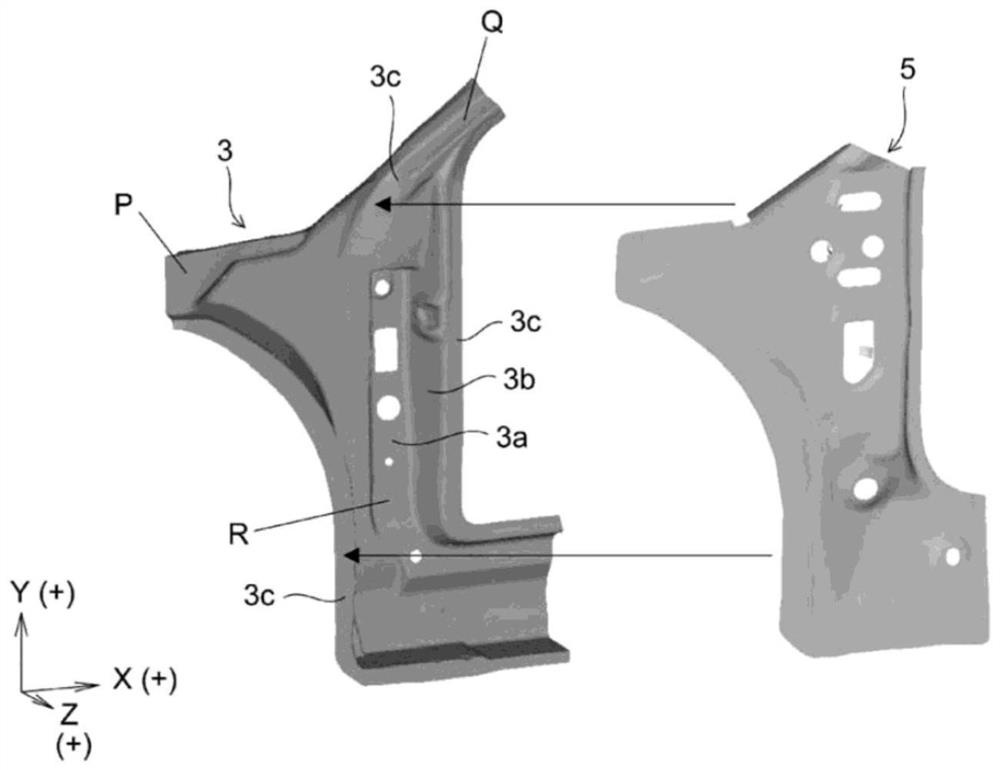

[0102] In Example 1, as a skeleton part for an automobile, the Figure 7 as well as Figure 8 The optimal shape of the reinforced component model shown in 9 to set figure 1 as well as figure 2 The A-pillar lower side 1 of the reinforcement member 7 shown is an example of the invention, and the rigidity and weight reduction of the A-pillar lower side 1 were evaluated.

[0103] The A-pillar underside 1 according to Invention Example 1 is formed by joining the outer panel 3 and the inner panel 5, and the outer panel 3 and the inner panel 5 are alloys with a tensile strength of 440 MPa and a thickness of 1.0 mm. Manufactured by stamping hot-dipgalvannealed steel sheet.

[0104] Reinforcement part 7 ( figure 2 ) is based on the shape optimization analysis method describ...

Embodiment 2

[0131] Similar to the above-mentioned Example 1, an experiment was conducted to verify the effect of improving the rigidity and reducing the weight of the automobile frame member according to the present invention, and therefore it will be described below.

[0132] In this second embodiment, based on the analysis results of the shape optimization analysis, it is set Figure 15 as well as Figure 16 The shape and arrangement of the reinforcing member 33 shown were used to evaluate the rigidity and weight reduction of the A-pillar lower side 31 where the reinforcing member 33 was set.

[0133] First, setting of the shape and arrangement of the reinforcing member 33 by the shape optimization analysis method will be described.

[0134] exist Figure 18 An optimization analysis model 51 in the shape optimization analysis is shown in . The optimization analysis model 51 sets a design space in the space formed by the outer panel 3 and the inner panel 5 , and sets a reinforcement m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com