An anti-warping star wheel of a single-screw compressor and its manufacturing process and installation process

A single-screw compressor and production process technology, applied in the field of power machinery, can solve the problems of difficult to achieve flatness, deformation and warpage of the star wheel, and leakage of compressed gas, and achieve the effect of reducing the reserved gap and reducing the amount of medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

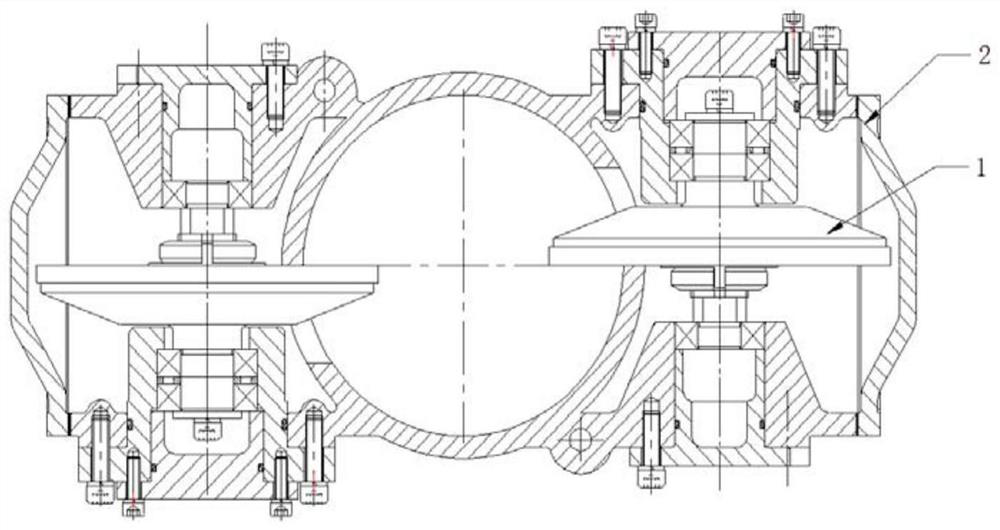

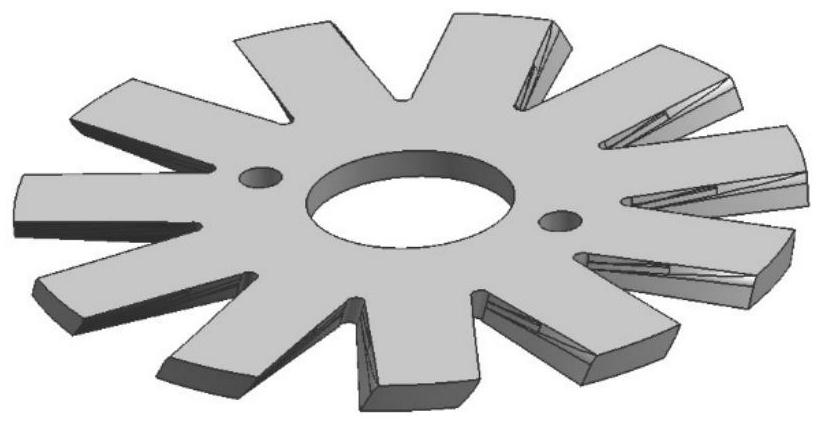

[0031] see Figure 2 to Figure 5 As shown, a manufacturing process of an anti-warping star wheel of a single-screw compressor, including:

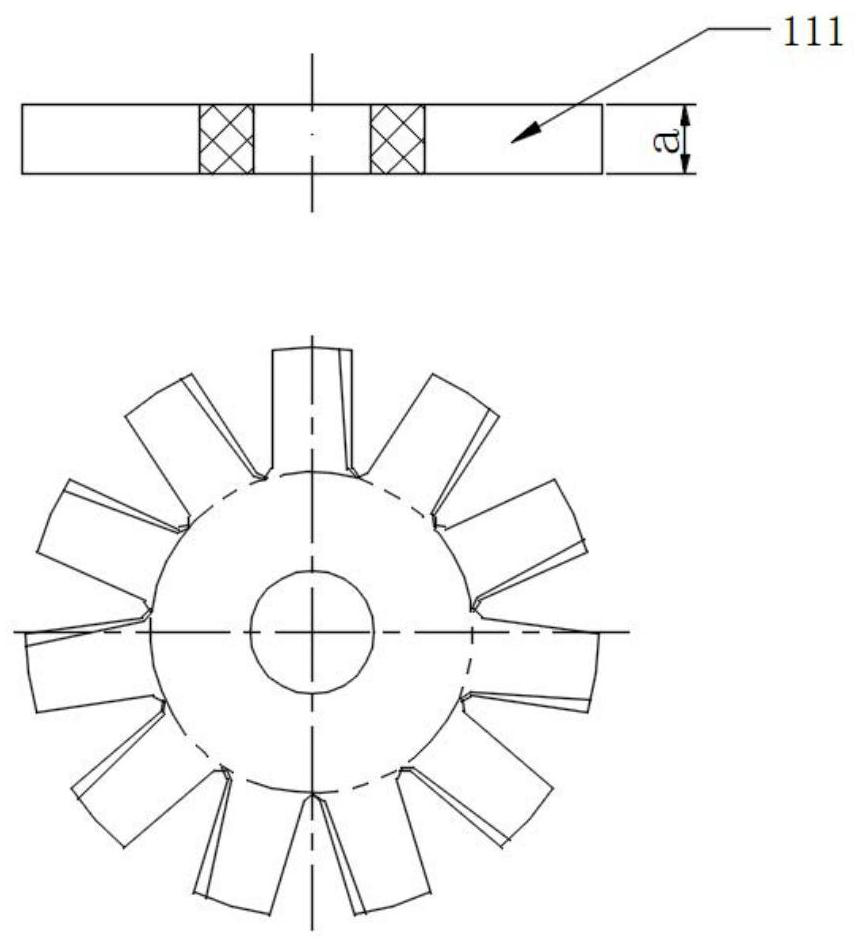

[0032] Make a plastic star wheel blank 111 according to the commonly used single-screw compressor star wheel manufacturing process. The thickness of the commonly used star wheel blank is generally a = 6 ~ 12mm, and the meshing tooth surface of the star wheel also leaves sufficient space Machining allowance. The star wheel blank is subjected to artificial aging treatment or natural aging treatment to make it deform freely. Then process a star wheel blank with good parallelism and flatness of both ends in a free state, and the parallelism and flatness of both ends should meet the requirements of free tolerance, such as image 3 shown.

[0033] The middle part of one end face of the star wheel blank 111 is processed into a plane by turning or milling, and the processing amount c is 1-2 mm; the processing depth of the small diameter star wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com