Seal ring and centrifugal wheel sealing structure suitable for low-temperature environment

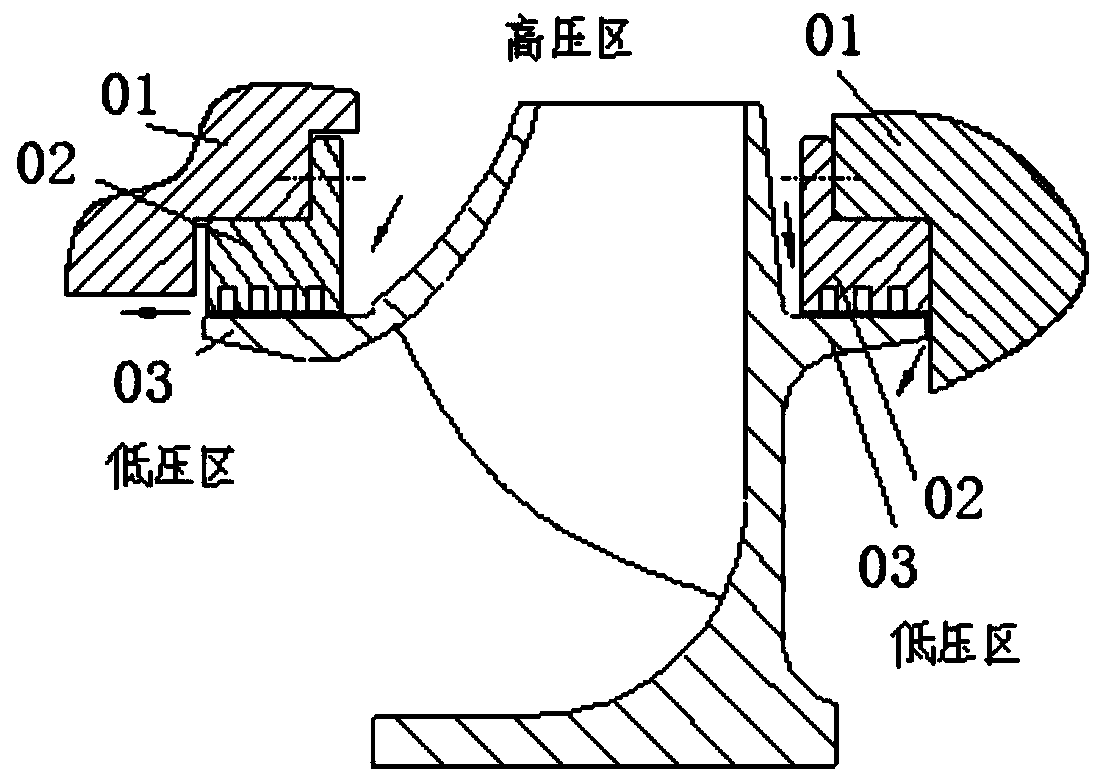

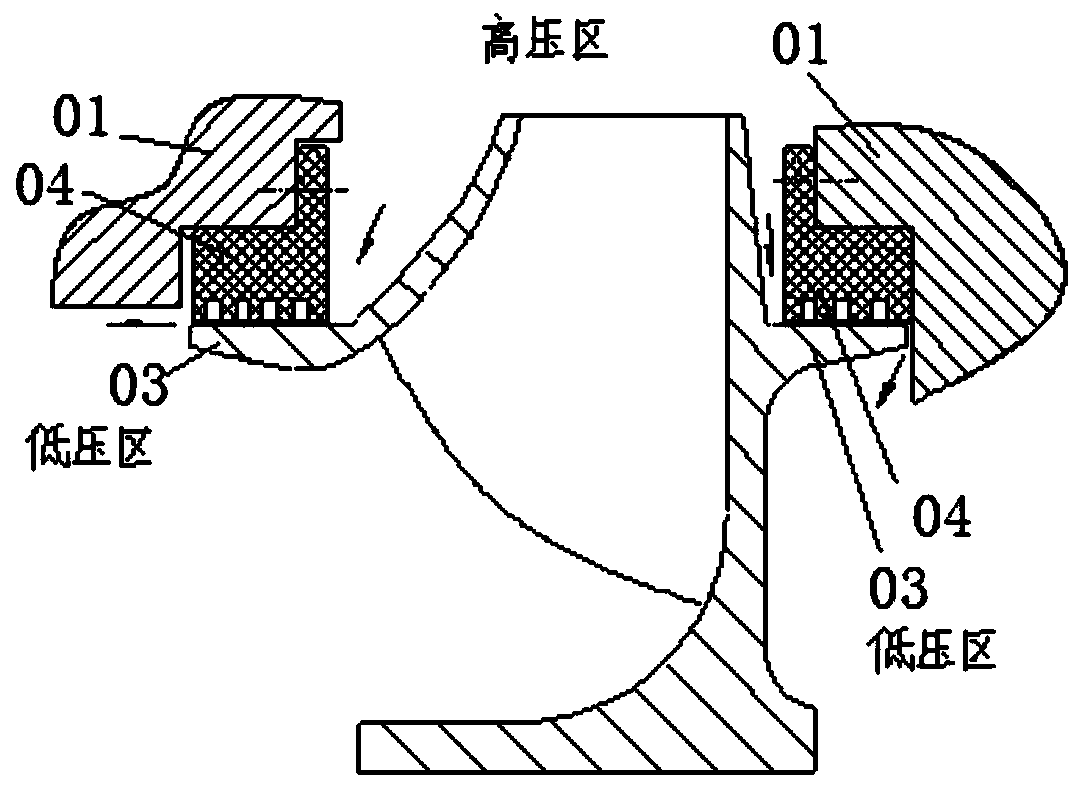

A technology of sealing structure and low-temperature environment, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve the variability of the overall stiffness of non-metallic sealing rings, centrifugal wheel seals Problems such as convex edge eccentric wear and reduced sealing effect can be achieved to achieve the effect of good sealing structure stability, enhanced overall rigidity and small gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

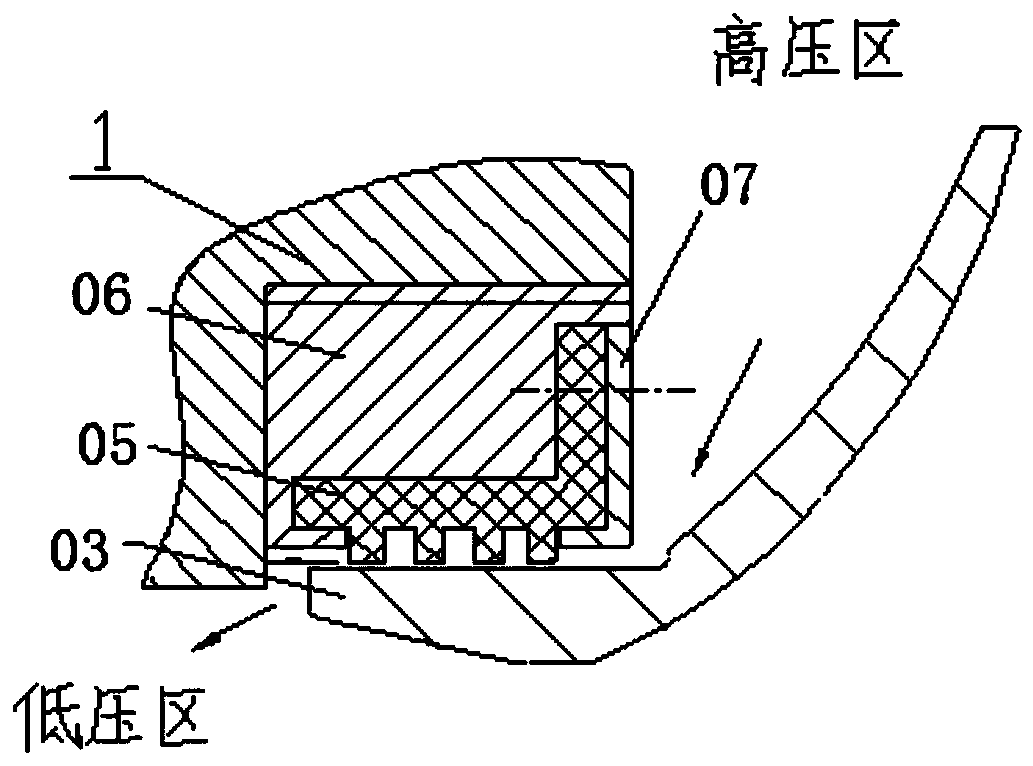

Embodiment 1

[0037] Such as Figure 4 to Figure 6 , a centrifugal wheel sealing structure suitable for low temperature environments, including a sealing ring; the sealing ring is sleeved outside the sealing flange 7 of the centrifugal wheel with a diameter of φ180mm, and the base 101 of the sealing shell 1 is fixed on the pump shell 6; wherein , the sealing ring includes a sealing shell 1, a metal annular plate 2 made of forged aluminum, a polytrifluoroethylene annular plate 3 and a pressure plate 4, and the sealing shell 1 is made of stainless steel with high rigidity; the sealing shell 1 includes a circular ring A shaped base 101 and a hollow cylindrical shell 102, the shell 102 is vertically fixed on the base 101. A plurality of polytrifluoroethylene annular plates 3 and a plurality of metal annular plates 2 are alternately placed in the housing 102, the number of polytrifluoroethylene annular plates 3 is 4, and the number of metal annular plates 2 is 3; the polytrifluoroethylene annula...

Embodiment 2

[0039] Such as Figure 4 to Figure 6 , a centrifugal wheel sealing structure suitable for low temperature environments, including a sealing ring; the sealing ring is sleeved outside the sealing flange 7 of the centrifugal wheel with a diameter of φ180mm, and the base 101 of the sealing shell 1 is fixed on the pump shell 6; wherein , the sealing ring includes a sealing shell 1, a metal annular plate 2 made of forged aluminum, a polytrifluoroethylene annular plate 3 and a pressure plate 4, and the sealing shell 1 is made of stainless steel with high rigidity; the sealing shell 1 includes a circular ring A shaped base 101 and a hollow cylindrical shell 102, the shell 102 is vertically fixed on the base 101. A plurality of polytrifluoroethylene annular plates 3 and a plurality of metal annular plates 2 are alternately placed in the housing 102, the number of polytrifluoroethylene annular plates 3 is 6, and the number of metal annular plates 2 is 5; the polytrifluoroethylene annula...

Embodiment 3

[0041] Such as Figure 4 to Figure 6, a centrifugal wheel sealing structure suitable for low temperature environments, including a sealing ring; the sealing ring is sleeved outside the sealing flange 7 of the centrifugal wheel, and the base 101 of the sealing casing 1 is fixed on the pump casing 6; wherein, the sealing ring includes The sealing case 1, the metal annular plate 2 made of forged aluminum, the polytrifluoroethylene annular plate 3 and the pressure plate 4, the sealing case 1 is made of stainless steel with high rigidity; the sealing case 1 includes a circular base 101 and a hollow cylindrical casing 102, the casing 102 is vertically fixed on the base 101. A plurality of polytrifluoroethylene annular plates 3 and a plurality of metal annular plates 2 are alternately placed in the housing 102, the number of polytrifluoroethylene annular plates 3 is 9, and the number of metal annular plates 2 is 8; the polytrifluoroethylene annular plates 3 is placed on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com