Bendable touch screen

A touch screen and bending technology, which is applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve problems such as fracture and inorganic film cracks, and achieve the goal of improving bending performance and retaining functional performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

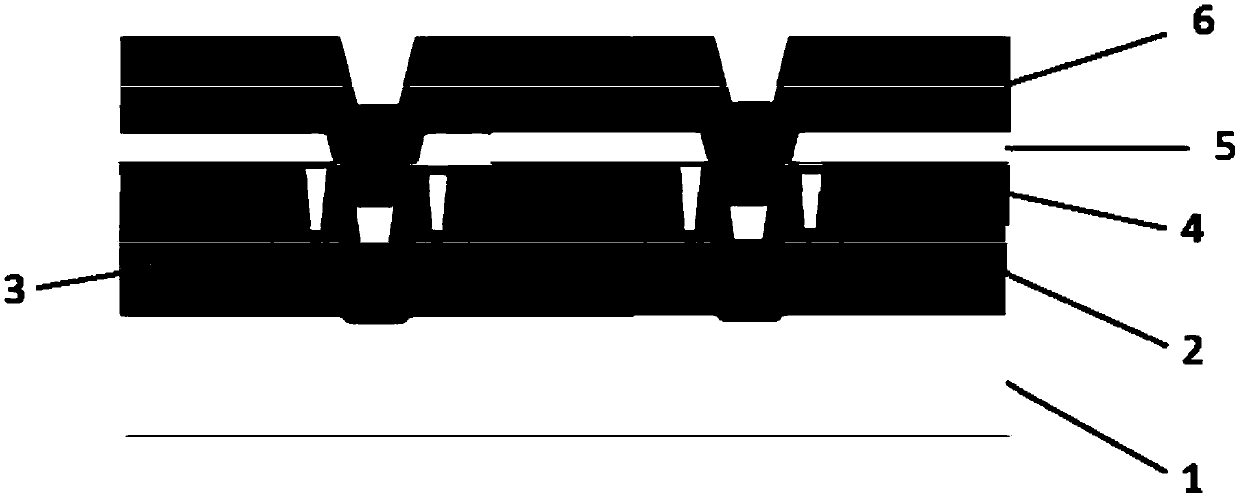

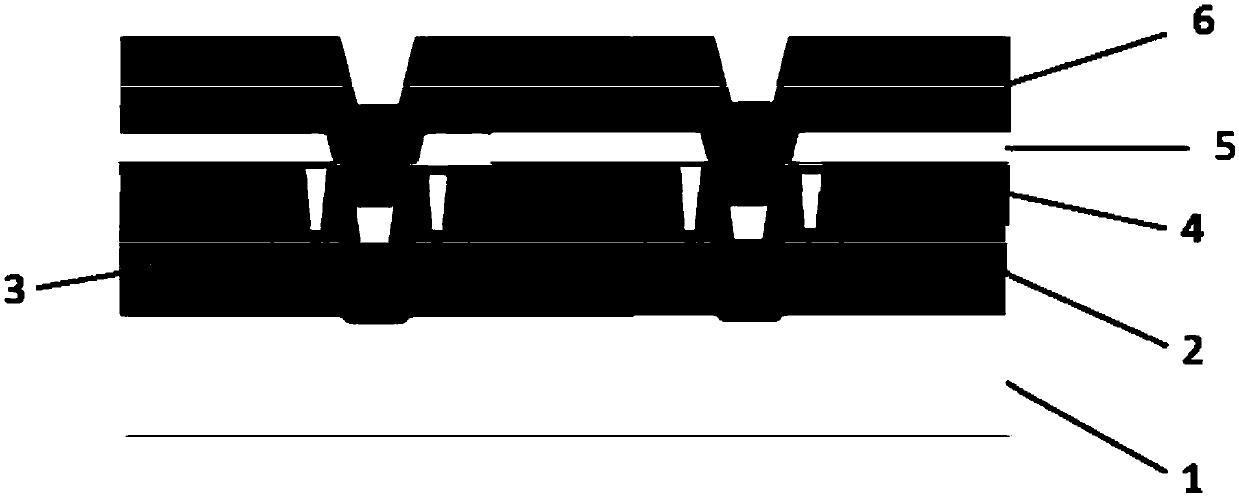

[0028] The preparation method of the wiring area is as follows: coating the insulating material on the surface of the substrate, forming a concave structure on the surface of the insulating material through a yellow light process, forming a first insulating layer, and making the first insulating layer of the functional area and the wiring area at the same time, using The PVD or laser process deposits or coats the conductive material inside the depression of the first insulating layer to form the third metal layer, and then uses the coating process to coat the insulating material on the third metal layer to obtain a protective layer. In the present invention, the substrate of the functional area and the wiring area is the same substrate, and the protective layers of the functional area and the wiring area can be prepared at the same time.

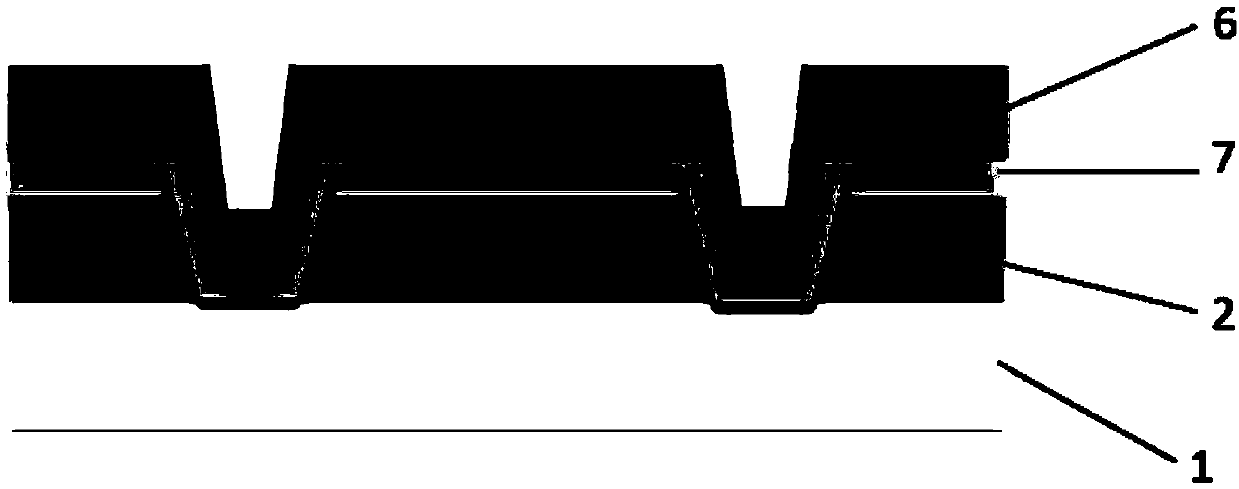

[0029] In the present invention, first, the yellow light process forms a concave structure on the surface of the first insulating layer, and...

Embodiment 1

[0034] When the substrate is CPI (10um), the in-plane conductive material is relatively brittle ITO, and the out-of-plane wiring area uses Ti / Al / Ti, this structure can achieve a bending radius of 2mm and a bending frequency of 200,000 times. , its touch function is still normal.

Embodiment 2

[0036] When the base material is PET (50um), the in-plane conductive material is Metal Mesh, and the out-of-plane wiring area uses Ag, the bending radius of this structure can reach 2mm, and the touch function can still be achieved when the bending times are 200,000 times. normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com