AVG conveying device

A conveying device and a technology for installing components, which is applied in the field of AGV conveying devices, can solve the problems of drivers or passengers being affected, difficult to dismantle and repair, and many civil works, and achieve the effects of high safety, good stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

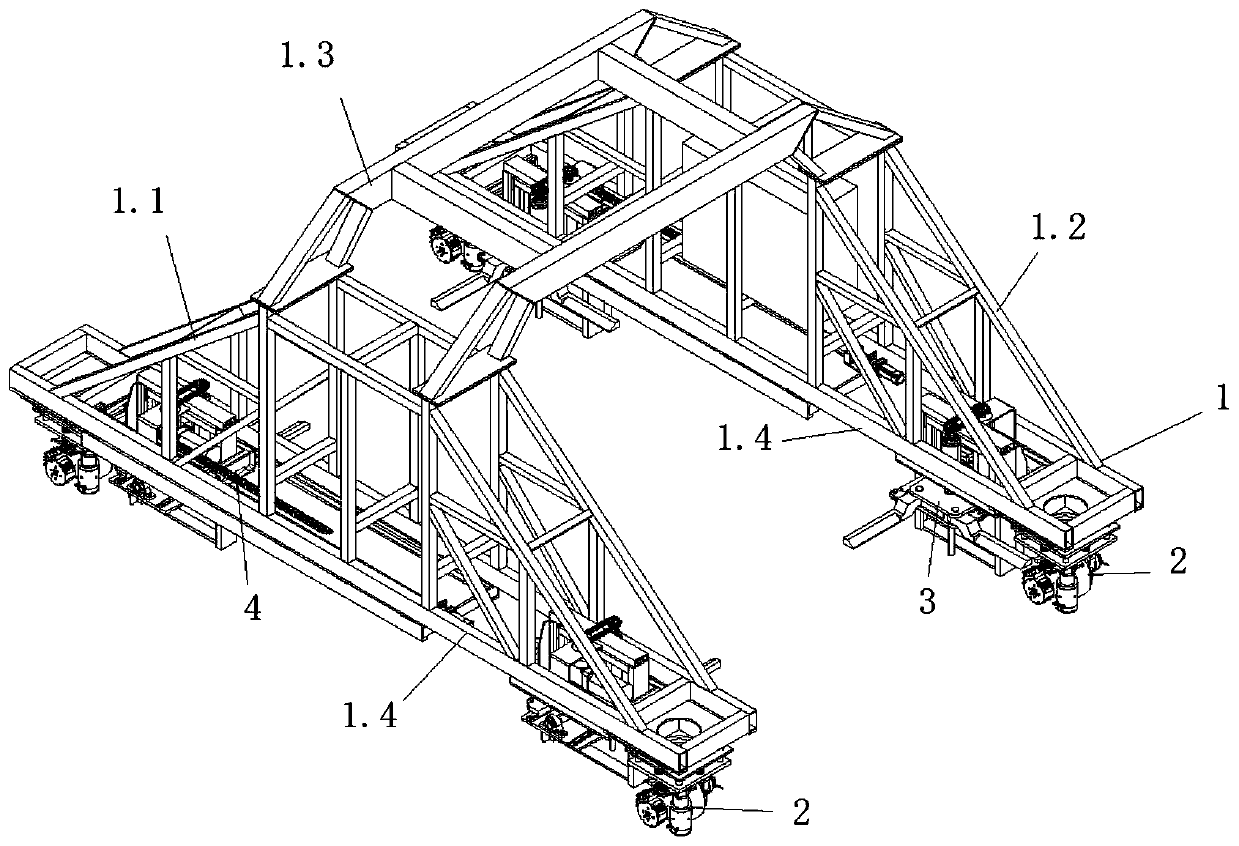

[0038]An AVG conveying device, comprising a car body 1, a steering wheel mounting assembly 2, a wheel holding mechanism 3 and a wheelbase adjusting mechanism 4, see figure 1 ,Details are as follows:

[0039] The vehicle body 1 includes a first vehicle frame 1.1, a second vehicle frame 1.2 and a connecting frame 1.3, and the two ends of the connecting frame 1.3 are respectively connected with the first vehicle frame 1.1 and the second vehicle frame 1.2. Preferably, both the first vehicle frame 1.1 and the second vehicle frame 1.2 are composed of an upper structure and a lower structure, and the upper structure adopts a steel pipe truss structure; the first vehicle frame 1.1 and the second vehicle frame 1.2 are both along the length direction of the vehicle body A guide rail 1.4 is correspondingly provided, and the guide rail 1.4 is welded on the lower structure; the guide rail 1.4 adopts a U-shaped structure.

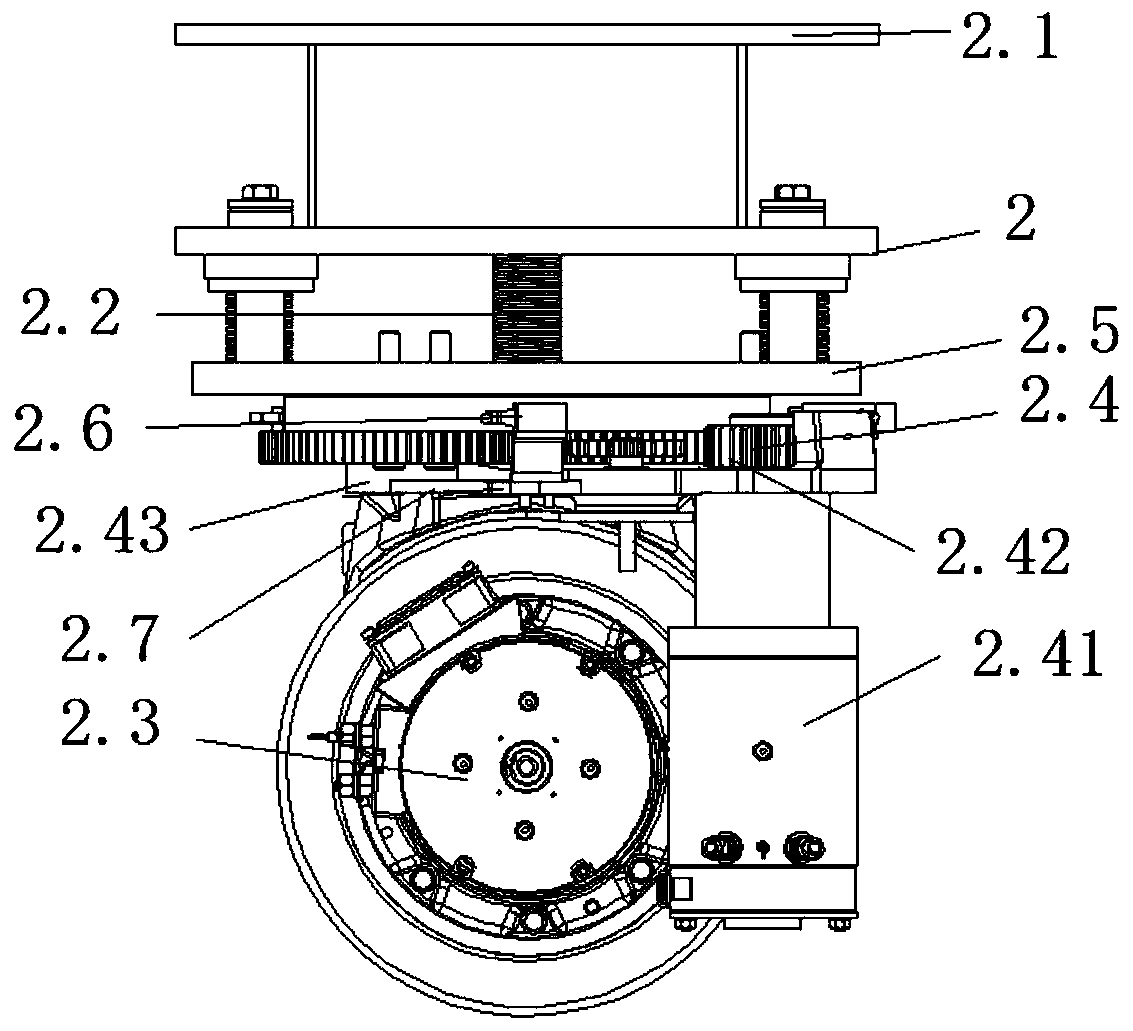

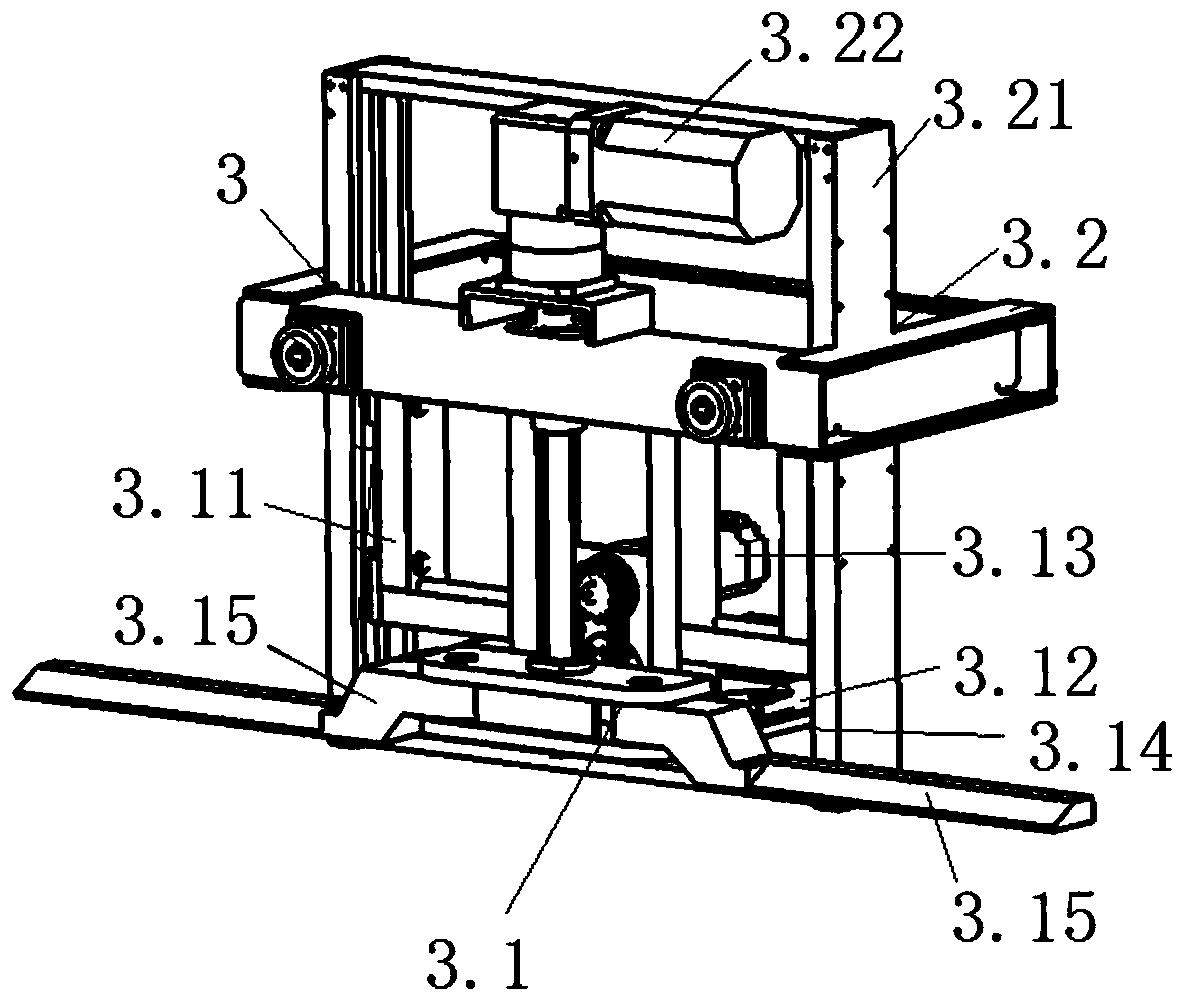

[0040] The steering wheel installation assembly 2 includes a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com