Multifunctional stringing pole-erecting machine

A pole machine and multi-functional technology, applied in the direction of building types, buildings, towers, etc., can solve the problems of low construction efficiency, high labor intensity, and difficulty in improving work efficiency, and achieve low labor intensity, high construction efficiency, and easy construction. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

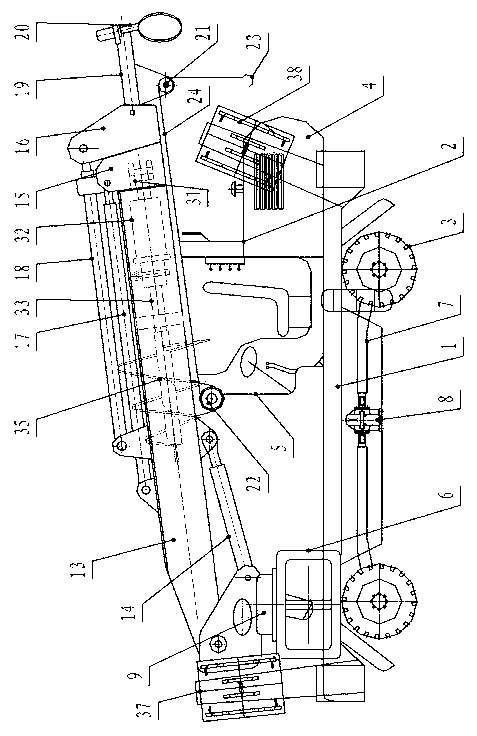

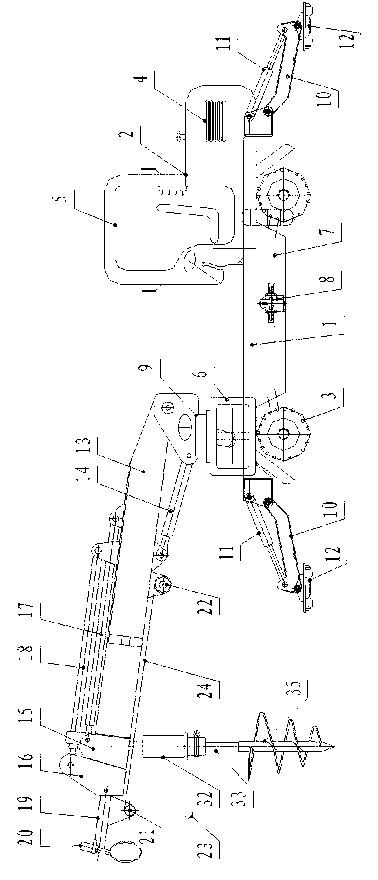

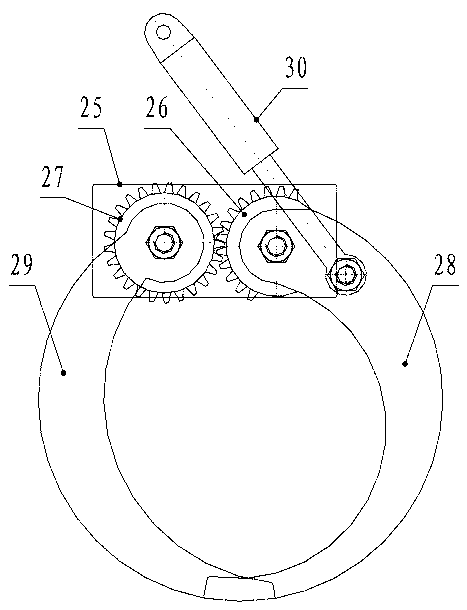

[0022] Such as Figure 1 ~ Figure 4 As shown, the multifunctional wire erecting pole machine of the present invention includes a power-operated vehicle 2 with a walking chassis 1, a walking wheel 3 is provided at the lower part of the walking chassis 1, and a power mechanism 4 and a driving control room 5 are provided at the rear of the walking chassis 1 , The front part of the traveling chassis 1 is provided with a slewing support 6. The power mechanism 4 is connected to the traveling wheel 3 through a transmission shaft 7 and a transfer case 8 located under the traveling chassis 1, and the power mechanism 4 is hydraulically connected to the slewing support 6. A rod lifting device is rotatably connected to the upper part of the rod 6 through the slewing base 9, and a drilling mechanism is provided under the rod lifting device. The front and rear ends of the walking chassis 1 are respectively provided with foldable front legs 37 and rear legs 38. Both the front leg 37 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com