Double-insurance pressed steel rope and processing method thereof

A double insurance, pressed steel technology, applied in textiles, papermaking, textile cables, etc., can solve the problem of low safety factor, and achieve the effect of high safety factor, improved friction, and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

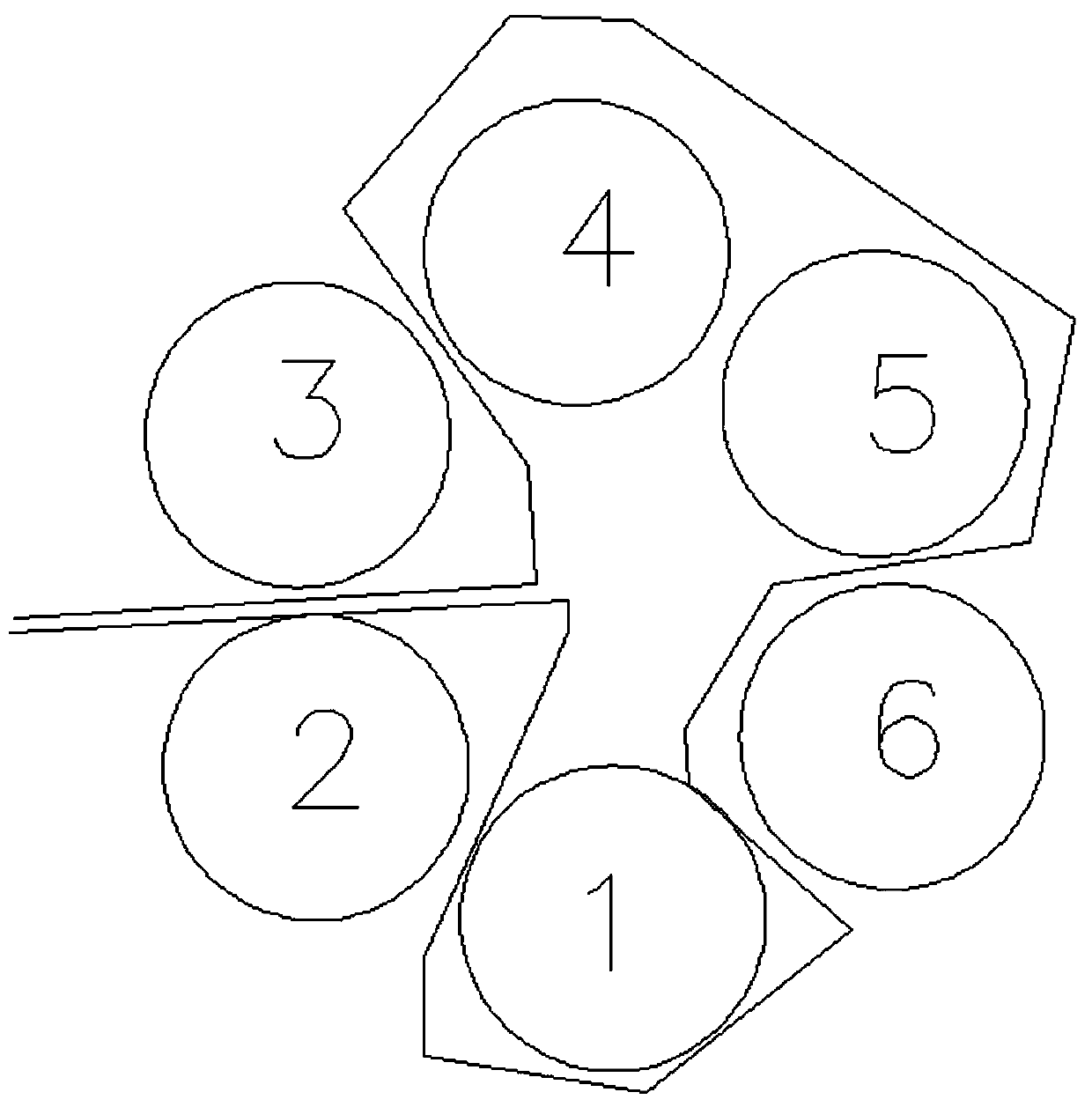

[0020] Below in conjunction with accompanying drawing, the rope body twisted according to 6 strands of steel rope is example, the specific embodiment of the present invention is described in further detail:

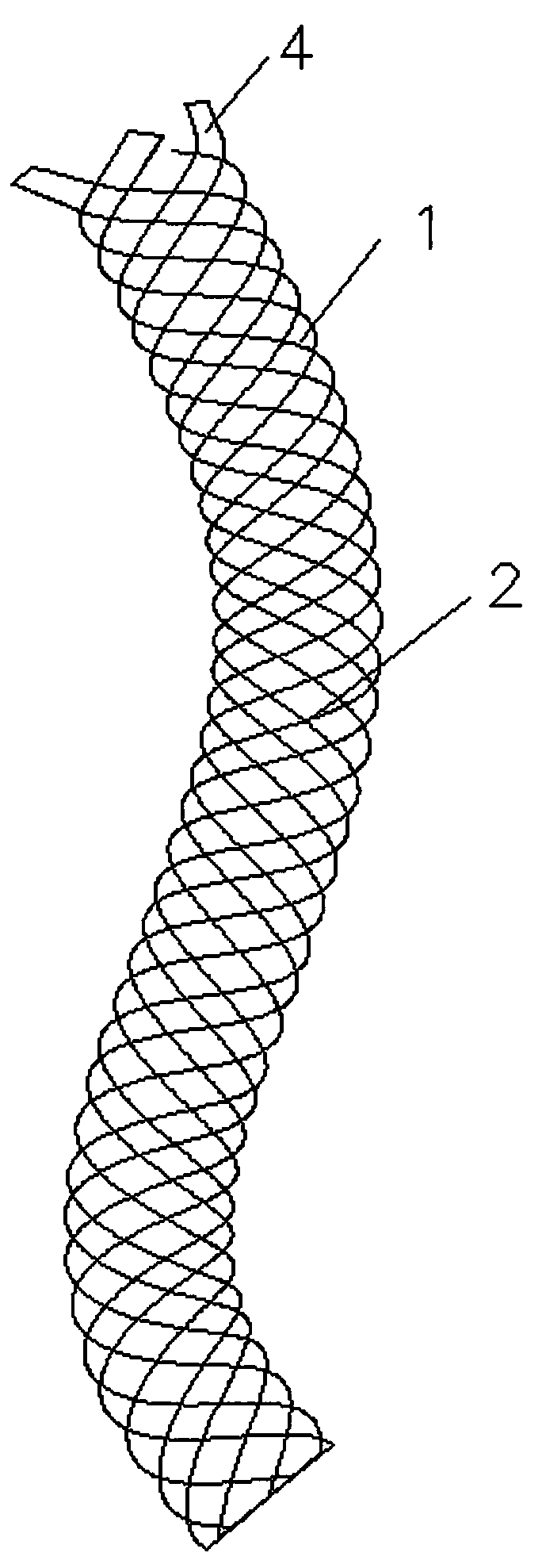

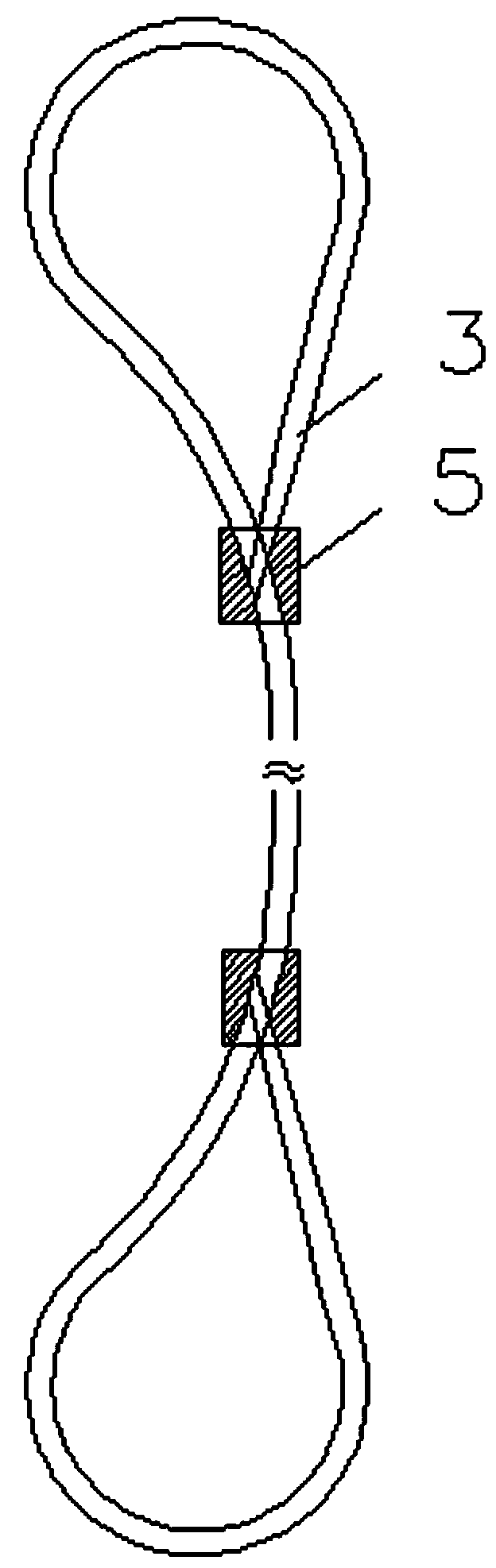

[0021] Such as figure 1 , as shown in 2, the double-safety pressed steel rope includes a rope body 2 formed by rotating and interlaced twisting of six strands of steel rope 1 and lifting rings 3 at both ends of the rope body. The lifting ring 3 is inserted through the free end 4 of the six strands of steel rope After the body is twisted, the six strands of steel rope are interspersed back and forth three times at the cross section of the insertion joint, and the insertion is completed by using a steel needle to pry open the strands. After three insertions, the free ends of each strand of steel rope are adjacent to each other in the six strands of steel rope The 6 gaps formed between the steel ropes pass through and are twisted together with the rope body 2 of the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com