Gear engagement clearance adjusting mechanism

A technology of clearance adjustment and eccentric adjustment mechanism, which is applied to belts/chains/gears, mechanical equipment, transmission parts, etc., can solve the problems of gear transmission accuracy, transmission efficiency and transmission torque decrease, and difficult to control the clearance adjustment amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

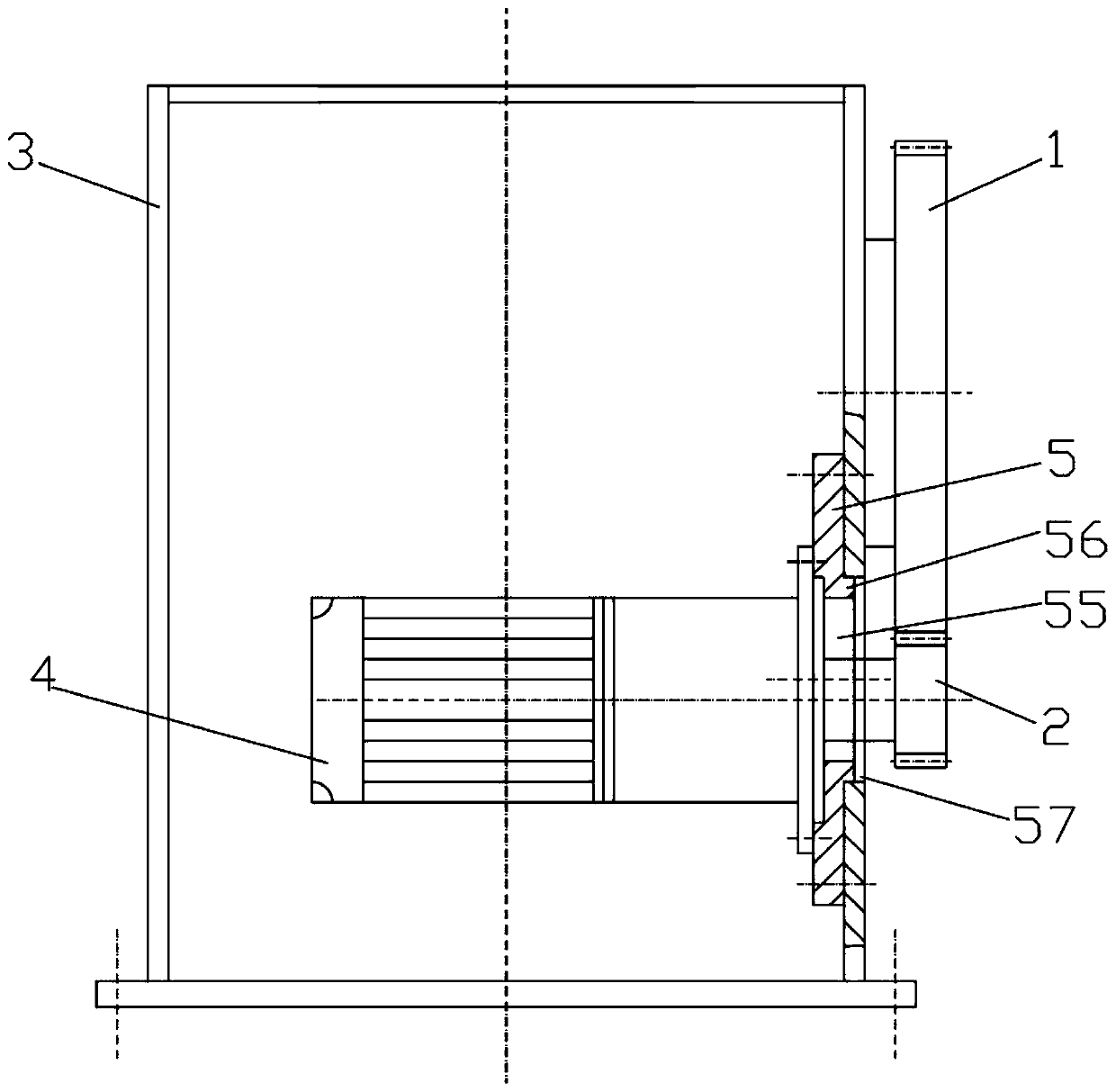

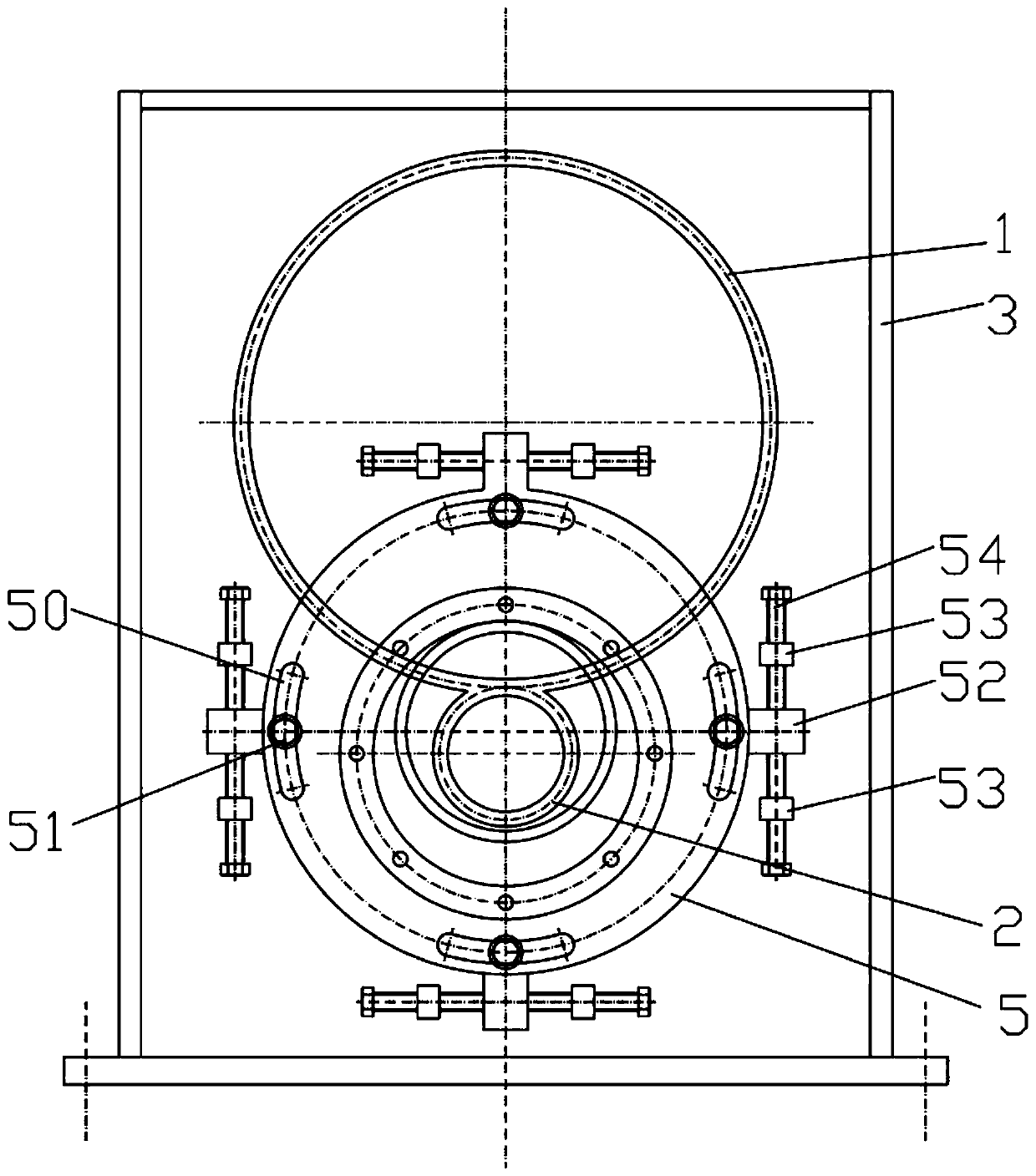

[0022] The present invention provides a gear meshing gap adjustment mechanism, which is used to adjust the meshing gap between the large gear 1 and the pinion 2 of the mutual meshing transmission, and its structure is as follows figure 1 and figure 2 shown. The gear meshing gap adjustment mechanism includes a column 3 and a motor 4, an eccentric disc 5 is rotatably mounted on the column 3, the motor 4 is eccentrically arranged on the eccentric disc 5, and is fixedly installed on the eccentric disc 5 On one side, the output shaft of the motor 4 passes through the eccentric disc 5 and is coaxially fixedly connected with the pinion 2; the gear mesh adjustment mechanism also includes an eccentric adjustment mechanism for adjusting the Eccentricity.

[0023] Specifically, please refer to figure 2 , the eccentric adjustment mechanism includes several arc-shaped slots 50 and several positioning bolts 51, and several arc-shaped slots 50 are opened on the eccentric disk 5 along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com