An adjustable fine boring tool

An adjustable, fine-boring technology, applied in the attachments of tool holders, tools for lathes, turning equipment, etc., can solve the problems of poor fine-tuning accuracy, poor cutting performance, and easy wear of fine-tuning mechanisms, so as to reduce wear, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

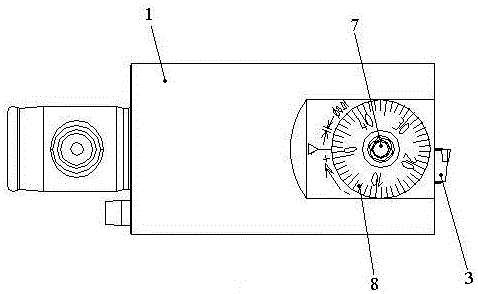

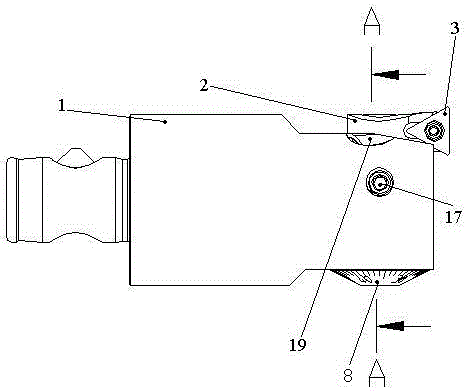

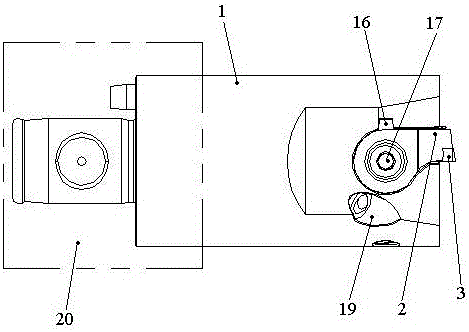

[0043] See attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 The present invention is further described.

[0044] The present invention relates to an adjustable fine boring cutter, which is characterized in that the structure includes a cutter body 1, a cutter head 2 and a blade 3, the head of the cutter body is provided with a combination hole 21, and one end of the combination hole 21 is provided with an internal thread;

[0045] The side of the cutter body 1 is provided with a trapezoidal groove 16 parallel to the generatrix of the combination hole 21;

[0046] The inner side of the cutter head 2 close to the inner side of the combination hole 21 is provided with an end surface tooth groove;

[0047] The side of the head of the cutter body 1 is provided with a radial threaded hole, and the radial locking screw 17 is screwed into the radial threaded hole;

[0048] The head of the cutter body 1 is also provided with a positioning disc 9, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com