Double-wheel milling mixing device and construction method for foundation treatment and vertical anti-seepage treatment

A foundation treatment and mixing device technology, which is applied in the direction of construction, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve the problem of low single-axis mixing efficiency, and achieve effective mixing efficiency and low cost. Low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

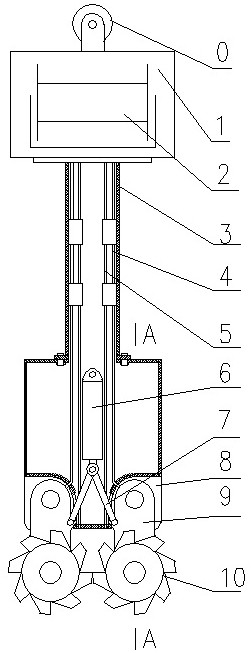

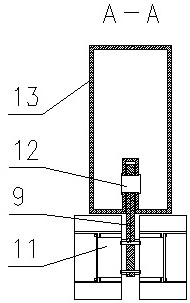

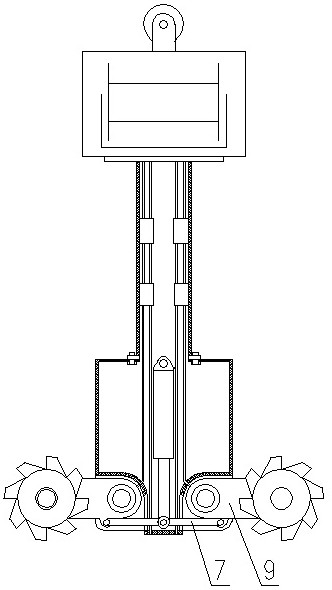

[0029] like Figure 1-Figure 3The shown double-wheel milling and stirring device for foundation treatment and vertical anti-seepage treatment is provided with a guide mounting frame 1 for connecting with the main engine 14, and a liftable connecting device 0 is provided on the upper side of the guide mounting frame 1. It can be seen from the figure Out, the connecting device 0 is a fixed pulley. A pressure winch 2 is arranged in the guide mounting frame 1, a hollow milling connecting rod 3 is arranged on the lower side of the guiding mounting frame 1, and a hydraulic oil pipe 4, a grouting pipe 5 and an air pipe are fixedly installed in the milling connecting rod 3, which are respectively used for Provide power for the hydraulic drive device, inject cement slurry, and inject compressed air to improve the stirring effect; the above structures are the same as those in the prior art, and will not be repeated. The characteristics of the present invention are: the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com