Vacuum transmission processing equipment and method

A technology of vacuum transmission and process equipment, which is applied in the direction of conveyor objects, transportation and packaging, and final product manufacturing. It can solve the problems of low production efficiency, improve operational efficiency, improve operational reliability and stability, and reduce mechanical design. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

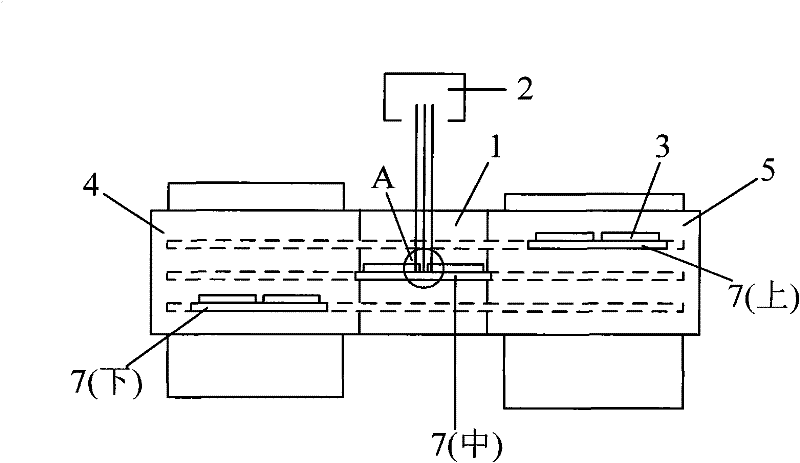

[0020] Such as figure 1 and figure 2 As shown, the vacuum transmission process equipment of the present invention first includes a vacuum process chamber 1 , and a processing device 2 is arranged in the vacuum process chamber 1 . The processing device 2 has a processing area A, and when the workpiece 3 passes through the processing area A, it will be processed by the processing device 2 . The present invention is not limited to the workpiece, for example, it may be a solar wafer. The present invention is not limited to the processing device, for example, it may be a device for processing a workpiece by ion beam or plasma, or it may be a device for heat treatment or annealing treatment of a workpiece.

[0021] One end of the vacuum process chamber 1 is provided with an inlet chamber 4 , while the other end is provided with an outlet chamber 5 . Both the inlet chamber 4 and the outlet chamber 5 can be realized by using a vacuum box with a smaller volume than the vacuum proce...

Embodiment 2

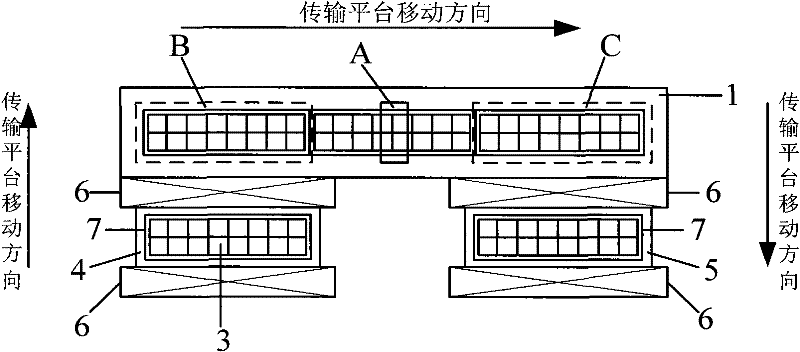

[0046] Such as image 3 As shown, in the vacuum transmission process equipment of the present invention, two above-mentioned inlet chambers 4 and / or two above-mentioned outlet chambers 5 can also be designed, wherein, the two inlet chambers can be respectively located in the vacuum process chamber 1 on both sides of one end ( image 3 The upper and lower sides of the chamber), the two output chambers can be respectively located on both sides of the other end of the vacuum process chamber 1 ( image 3 The upper and lower sides of the middle), such a design will still be able to ensure that: each transfer platform enters the vacuum process chamber 1 from any inlet chamber and enters any output chamber from the vacuum process chamber 1. The moving direction is the same as that of each transfer platform The moving direction in the vacuum process chamber 1 is vertical.

[0047]Due to the increase in the number of incoming and outgoing cavities, on the one hand, also for the purpo...

Embodiment 3

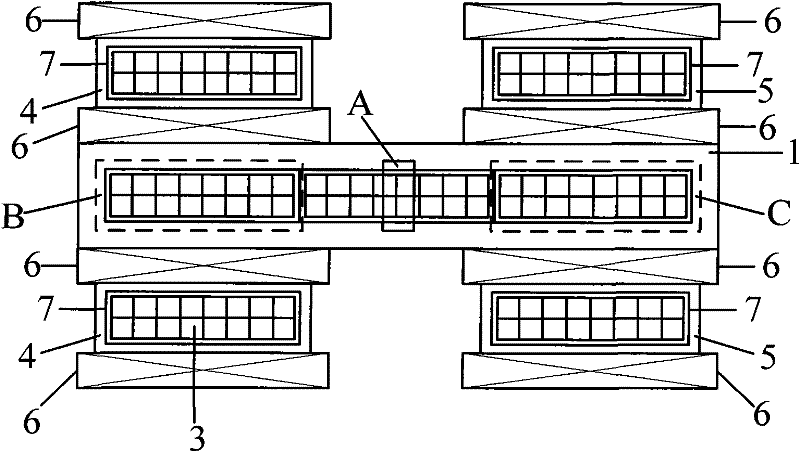

[0050] Such as Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is that in this embodiment, the inlet chamber 4 and the outlet chamber 5 are collinearly arranged with respect to the vacuum process chamber 1, that is, each transfer platform is The movement direction of the entry chamber 4 into the vacuum process chamber 1 and from the vacuum process chamber 1 into the exit chamber 5 is in line with the movement direction of each transport platform in the vacuum process chamber 1 . This provides convenience for docking the two ends of the vacuum transmission process equipment with other equipment in the system, thereby facilitating the realization of an automated production line for one-way conveyance of workpieces.

[0051] To sum up, in the present invention, each transmission platform can move through the processing area successively and continuously to perform the processing process on the workpiece on it, thereby obtaining extremely high prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com