Roller kiln sintering temperature control method and system

A technology of sintering temperature and control method, applied in the furnace control device, furnace, furnace type and other directions, can solve the problems of burning out heating components, power grid impact, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

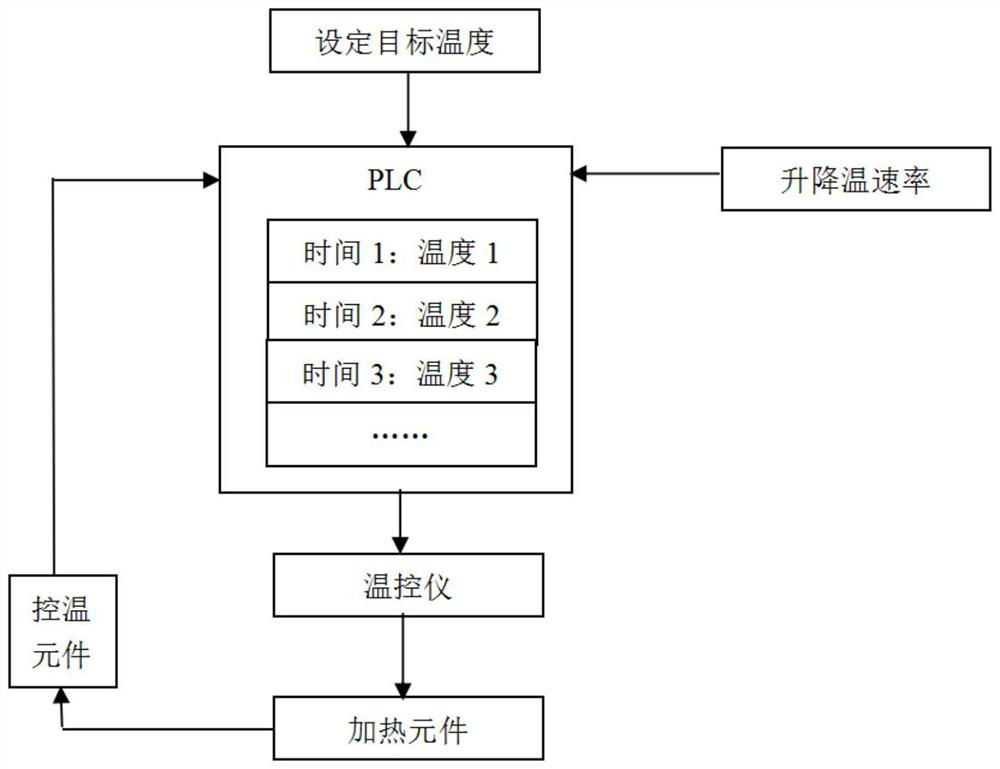

[0023] like figure 1 As shown, this implementation discloses a method for controlling the sintering temperature of a roller kiln, which includes the following steps:

[0024] Determine the scientific heating and / or cooling target temperature zone, the optimal heating rate and / or the optimal cooling rate of the roller kiln according to the material of the refractory lining of the roller kiln;

[0025] Calculate the target of each preset time node when the roller kiln is heated and / or cooled at the optimal heating rate and / or the optimal cooling rate in the target temperature zone of the roller kiln for heating and / or cooling temperature;

[0026] The heating power of the heating element of the roller kiln at each preset time node is controlled according to the target temperature at each preset time node, so that the heating element executes the target temperature at each preset time node.

[0027] In addition, in this embodiment, a computer system includes a memory, a process...

Embodiment 2

[0030] The second embodiment is an expanded embodiment of the first embodiment. The difference from the first embodiment is that the specific steps of the roller kiln sintering temperature control method are refined, and the structure and the structure of the roller kiln sintering temperature control system are detailed. The functionality has been expanded to include the following:

[0031] In this embodiment, according to the material of the lining of the roller kiln, the influence of heating and cooling on the service life of the lining is fully considered, especially the rapid heating and cooling is not conducive to the long-term use of the lining. Based on this, the target temperature zone is determined to achieve a more scientific heating / cooling down, including the optimal heating rate and / or the optimal cooling rate) specifically includes: according to the set optimal heating / cooling rate, in multiple consecutive fixed time periods (for example, 5s-adjustment) multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com