Manufacturing method of clothing shoulder tabs

A production method and a shoulder loop technology, which are applied in the field of garment processing, can solve the problems of unfavorable shoulder loops being turned out, difficult to handle, and hair picking, etc., and achieve the effects of beautiful shape, standardized movement and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is described in detail below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a restriction on the technical solution, and any equivalent transformations made according to the concept of the present invention are only formal and not substantive. It should be regarded as the scope of the technical solution of the present invention.

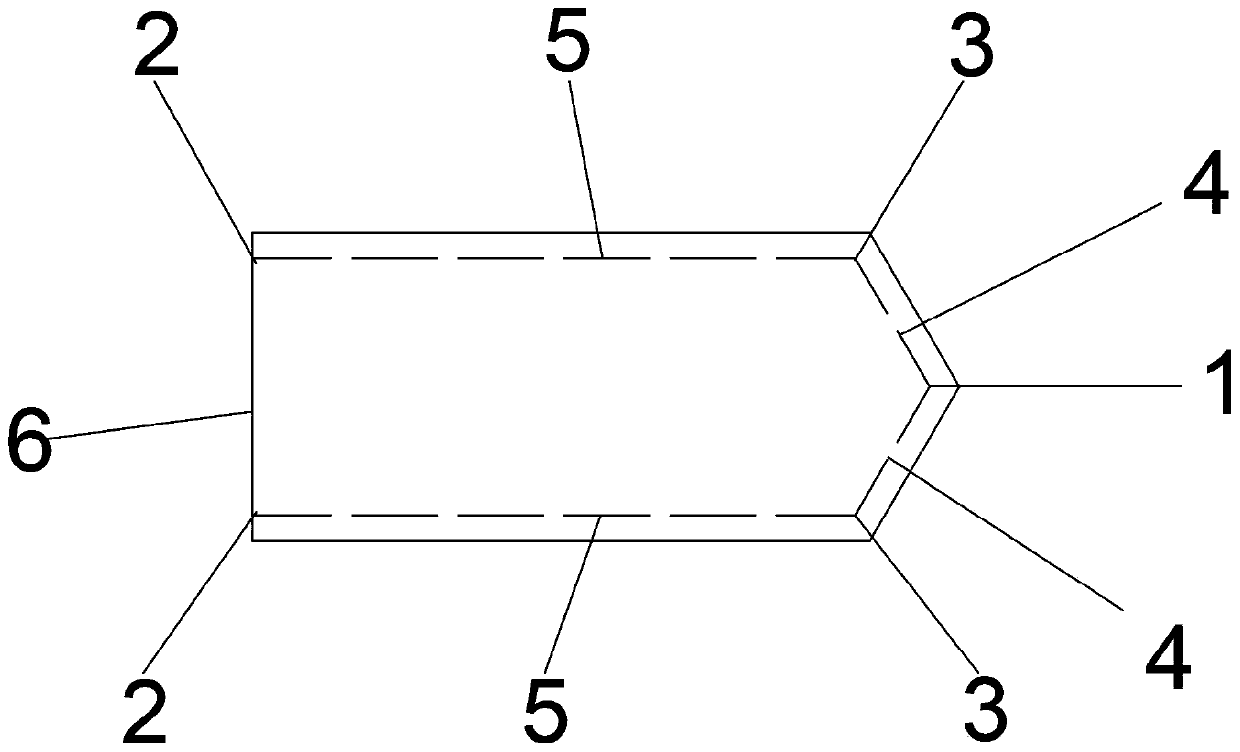

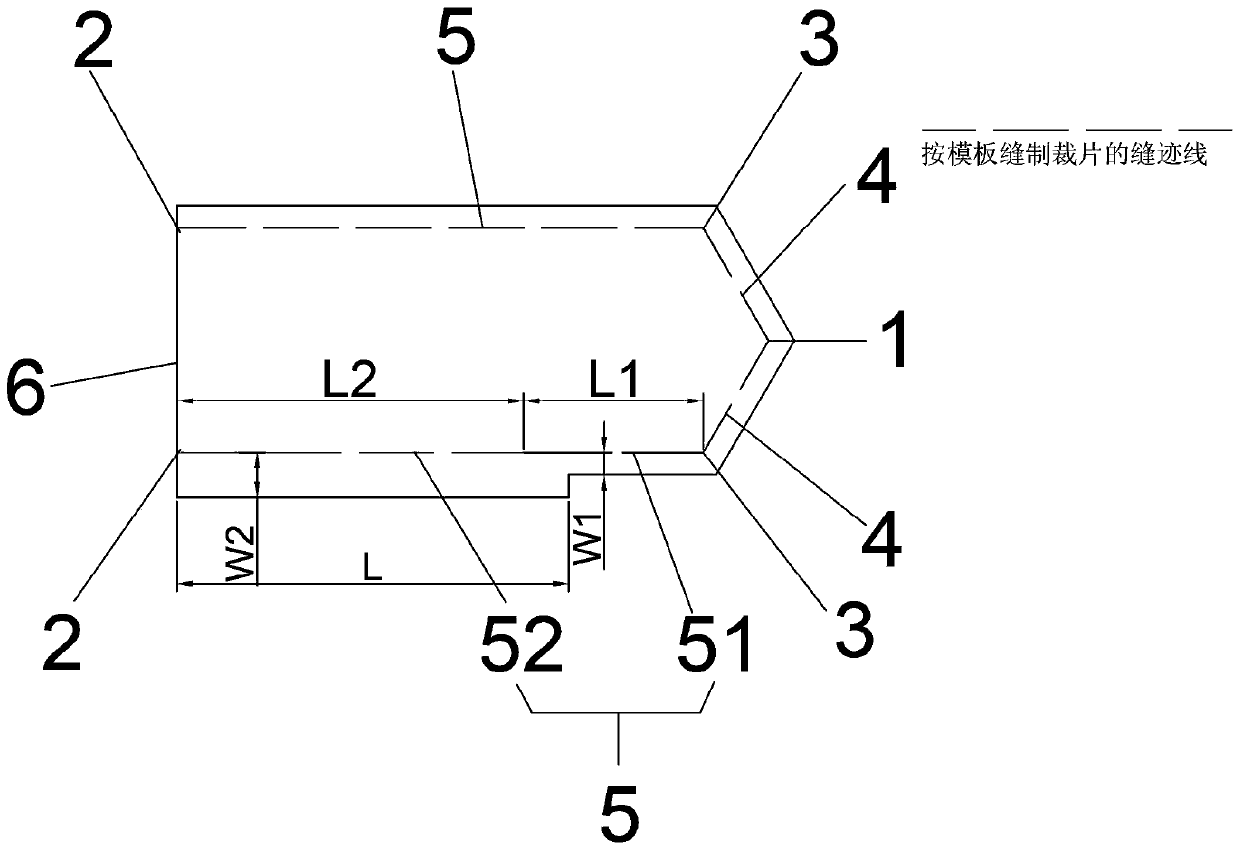

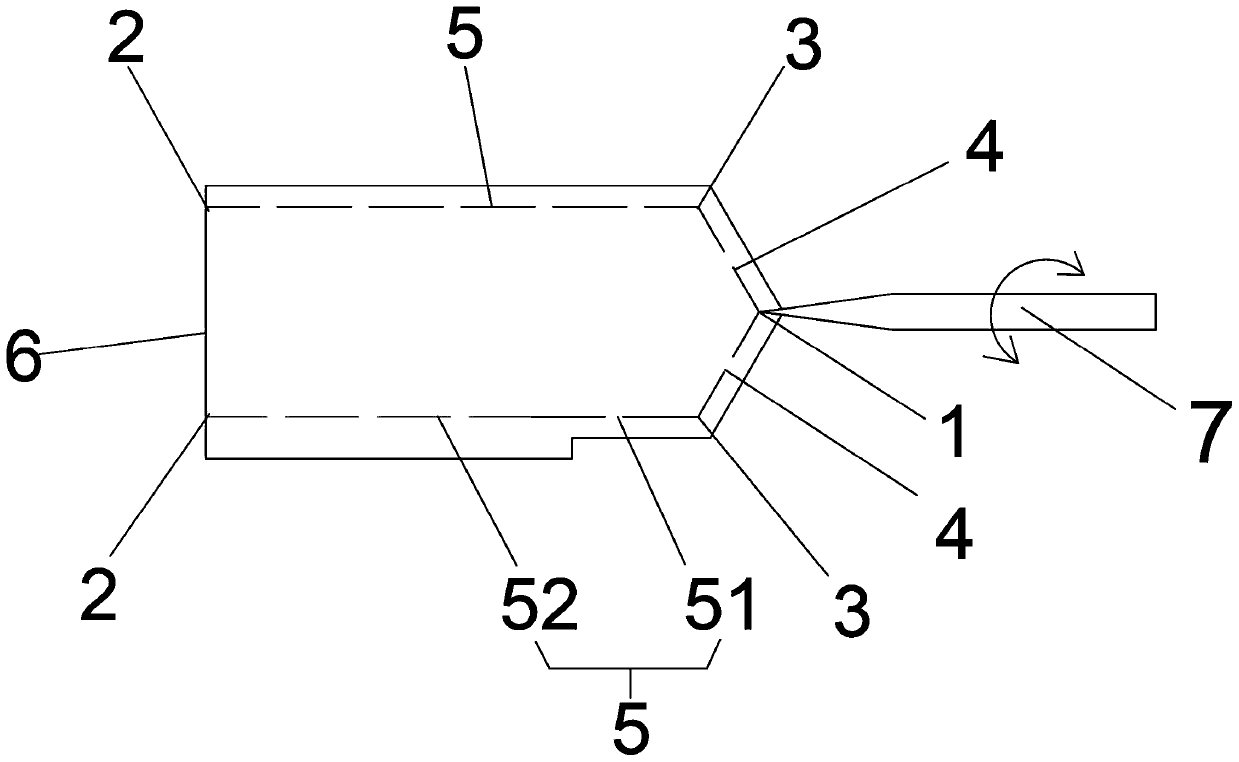

[0027] Such as Figure 1 to Figure 4 As shown, the present invention relates to a kind of manufacturing method of garment shoulder loops, shoulder loops are generally elongated and symmetrical pentagonal shape, correspondingly, the template used for making shoulder loops is also of this shape, and the cut pieces are sewn according to the template. The seam line is also in this shape. When the seam line is sewn on the cut piece according to the template, a sharp corner 1 at one end of the shoulder loop, two symmetrically arranged right ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com