A control method for automatic ladle casting of continuous casting machine

A control method and technology of a continuous casting machine, which are applied in the field of automatic casting control, can solve problems such as manual operation, and achieve the effects of reducing labor intensity, labor cost, and slag inclusion content in a slab.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the examples.

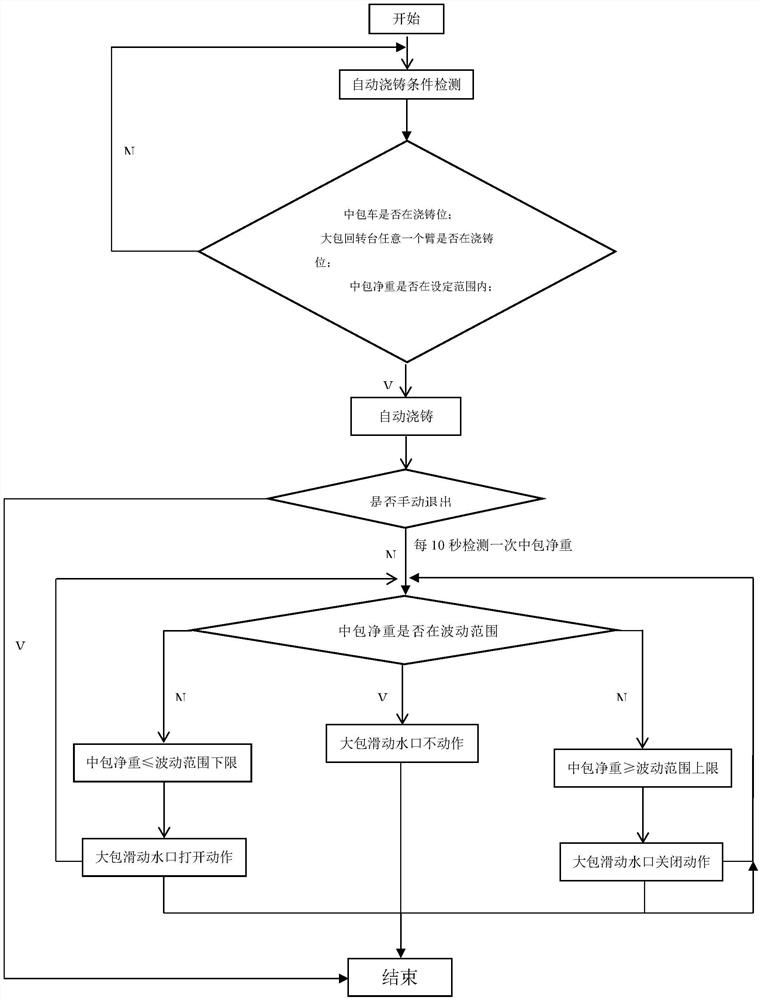

[0023] The invention discloses a control method for automatic ladle casting of a continuous casting machine. The opening control principle of the sliding nozzle is the same as the closing control principle, that is, it is opened or closed for a fixed time, and then the next opening or closing action is performed until the sliding nozzle is satisfied. The sliding nozzle closing or opening condition; then the sliding nozzle is closed or opened for a fixed time, and then the next closing or opening action is performed until the sliding nozzle opening or closing condition is met, and so on.

[0024] The specific process is:

[0025] S1. According to the size of the tundish’s own capacity, when the net weight of the tundish reaches a certain weight, press the automatic casting button of the large ladle sliding nozzle. At this time, the automatic pouring of the large ladle slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com