Full-automatic multi-angle label feeding mechanism

A labeling machine, multi-angle technology, used in labels, labeling machines, packaging and other directions, can solve the problems of food pollution and human health hazards, and achieve the effect of ensuring stable suction and improving suction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

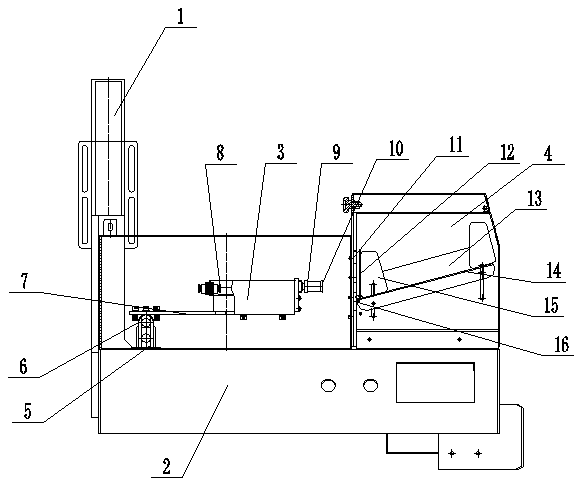

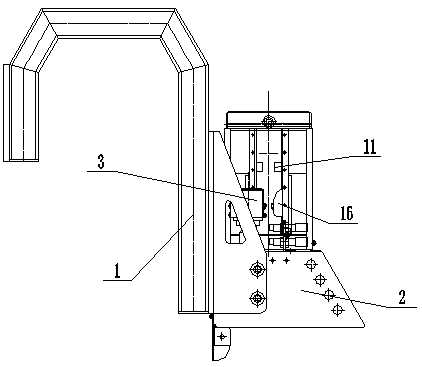

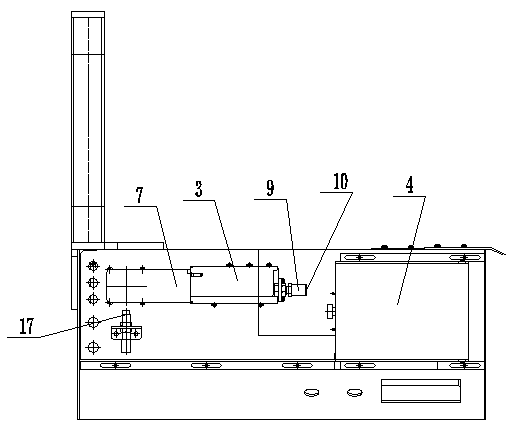

[0017] A fully automatic multi-angle labeling mechanism, which consists of: a labeling machine main body 2 and a labeling machine bracket 1, a deceleration motor is installed inside the labeling machine main body through bolts, and the output shaft 5 of the decelerating motor is passed through a shaft coupling The device 6 is fixed to one end of the rotating plate 7, which is fixed by bolts, and the other end of the rotating plate is fixed with a fixed plate 3 by bolts, and the fixed plate is fixed by bolts to the sliding table cylinder 8. The end of the push rod of the slide cylinder is fixed with a suction cup seat 9 through a nut, and the suction cup seat has a suction cup 10;

[0018] The right side of the main body of the labeling machine is fixed with a label box 4 with an opening on the left side, and the inside of the label box is fixed with a slideway plate 14 arranged obliquely. A plurality of labels 12 are placed on the slideway plate. There is a large block 15 on t...

Embodiment 2

[0021] According to the fully automatic multi-angle labeling mechanism described in Embodiment 1, side plates 13 are fixed on the front and rear sides of the slideway plate, and the side plates can limit the front and rear sides of the label to ensure that the label is on the edge of the slideway plate. Slide left and right along the slope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com