Electrical power cable winding device for electric engineering

A technology of power cable and wire take-up device, which is applied in the field of electrical engineering, can solve the problem of not having to replace the winding reel, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

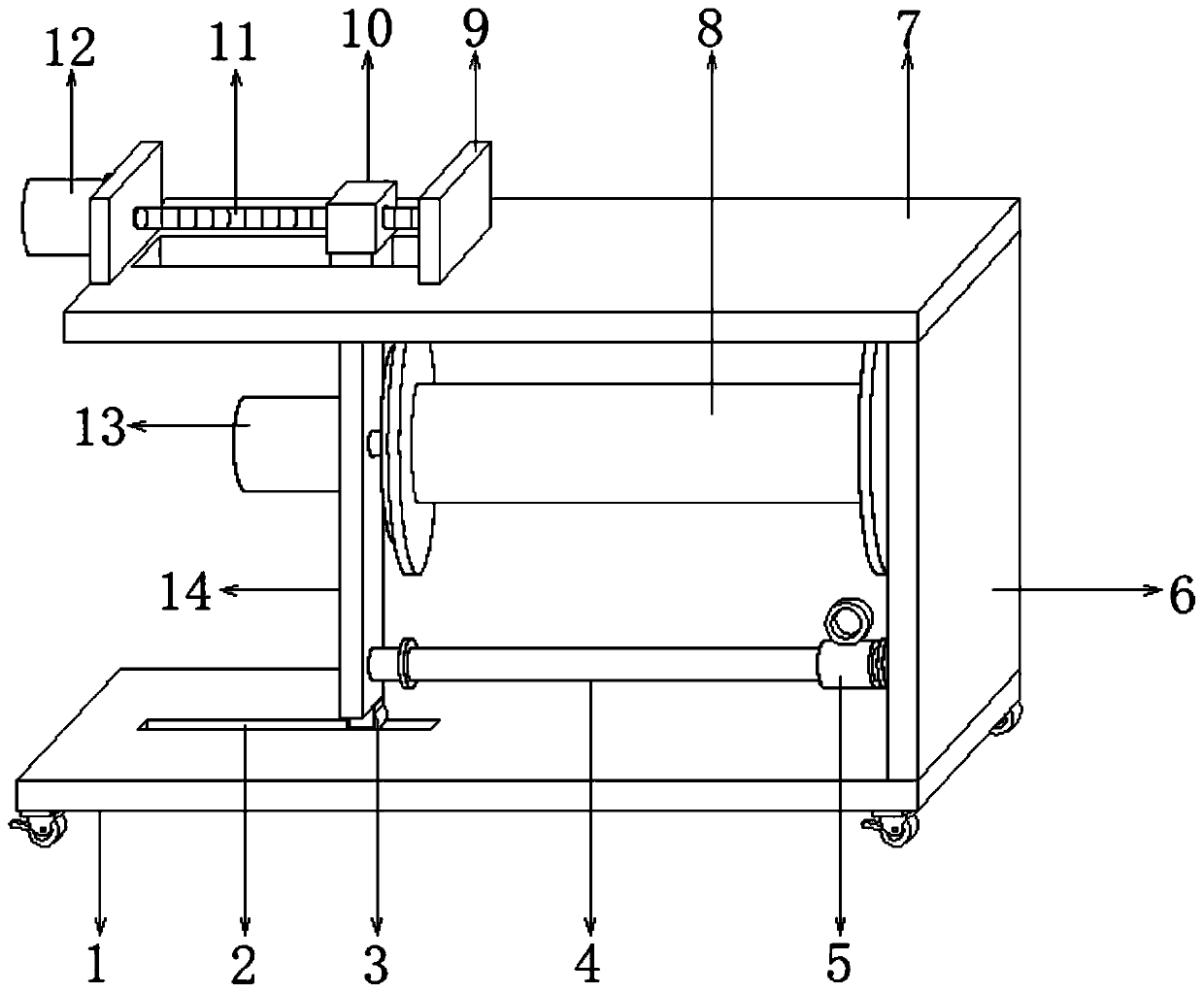

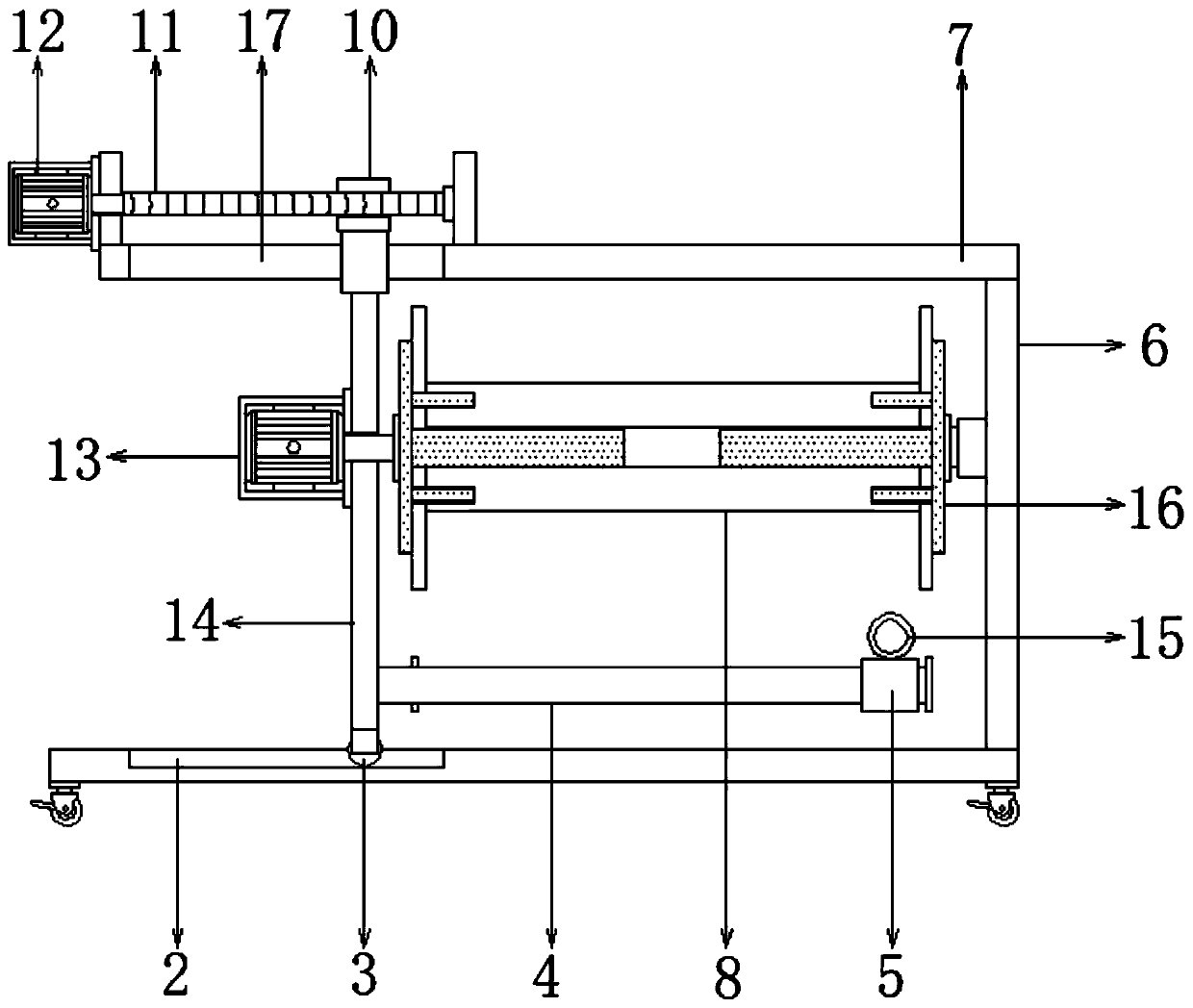

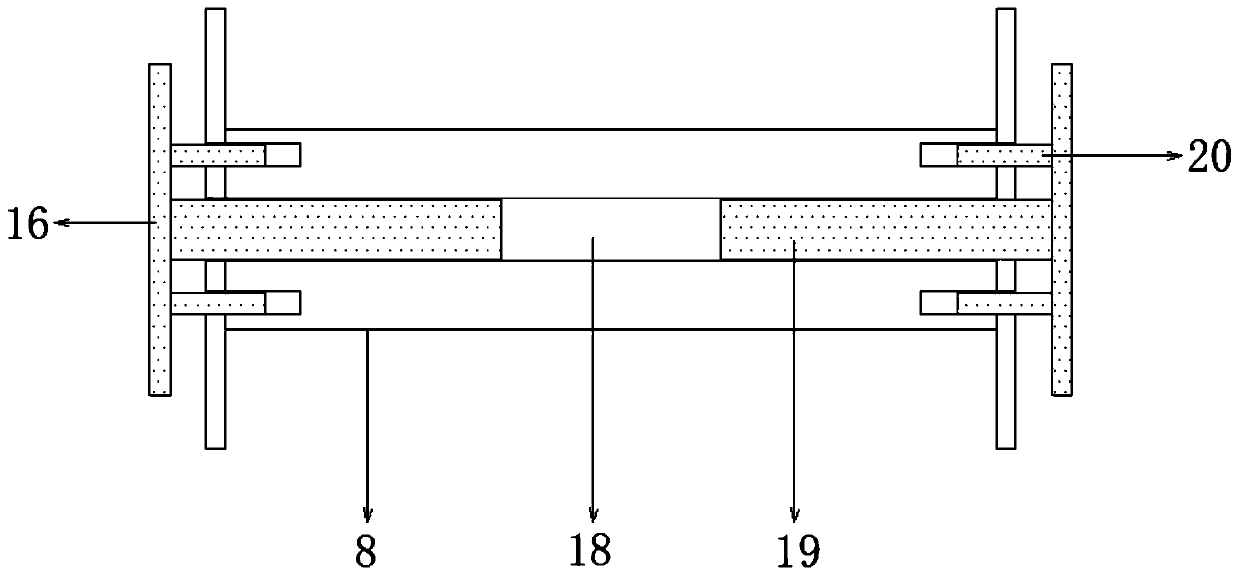

[0027] refer to Figure 1-3 , a power cable take-up device for electrical engineering, comprising a support base plate 1, a side plate 6 is welded to the top side of the support base plate 1, and a top plate 7 is welded to the top of the side plate 6, and the top end of the top plate 7 is connected to the top Both sides are welded with fixed seats 9, and one side of one of the fixed seats 9 is connected with a forward and reverse motor 12 by bolts, and the output shaft of the forward and reverse motors 12 is connected with a threaded lead screw 11 by bolts, and one end of the threaded lead screw 11 It is rotatably connected with one side of the other fixed seat 9, and the middle position of the top side of the top plate 7 has a second chute 17, and the outer wall of the threaded screw 11 is threaded with a movable sleeve 10, and the movable sleeve 10 The bottom is welded with a slider slidingly connected to the inner wall of the second chute 17, the bottom of the slider is wel...

Embodiment 2

[0035] refer to Figure 4 , a power cable take-up device for electrical engineering. Compared with Embodiment 1, this embodiment replaces the forward and reverse motor 12 with a handle 21, and the bottom of one side of the handle 21 is welded with a connecting rod, and the connecting rod One end passing through the fixing seat 9 is welded with one end of the threaded screw 11 .

[0036] Working principle: when in use, the user uses the turning handle 21 to drive the connecting rod to rotate in the fixed seat 9, to drive the threaded screw 11 to rotate, and to clamp and replace the winding reel 8 by manpower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com