Needle retracting structure for knitting machine

A knitting machine and moving mechanism technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of low efficiency, long time-consuming manual knitting, inability to adjust the number of knitting needles, etc., achieve reasonable layout, improve automation performance, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

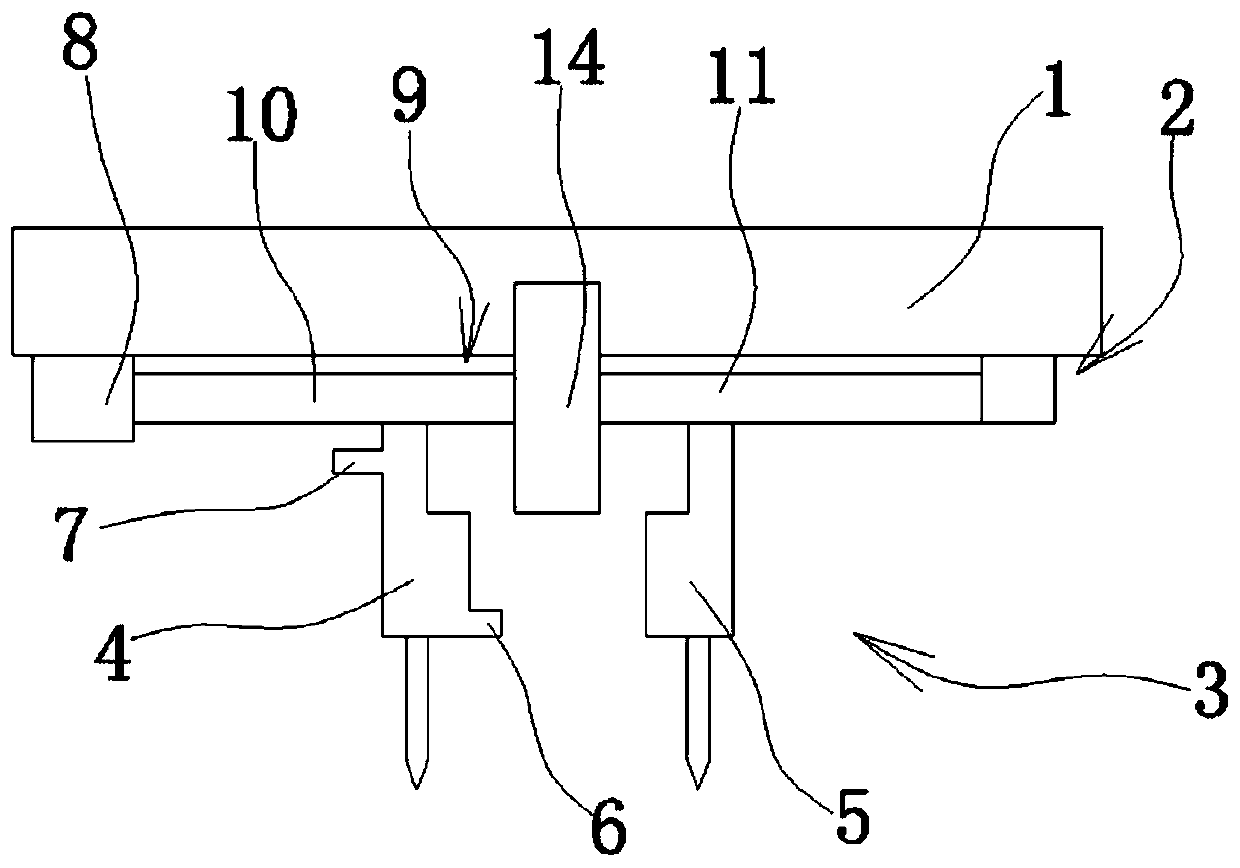

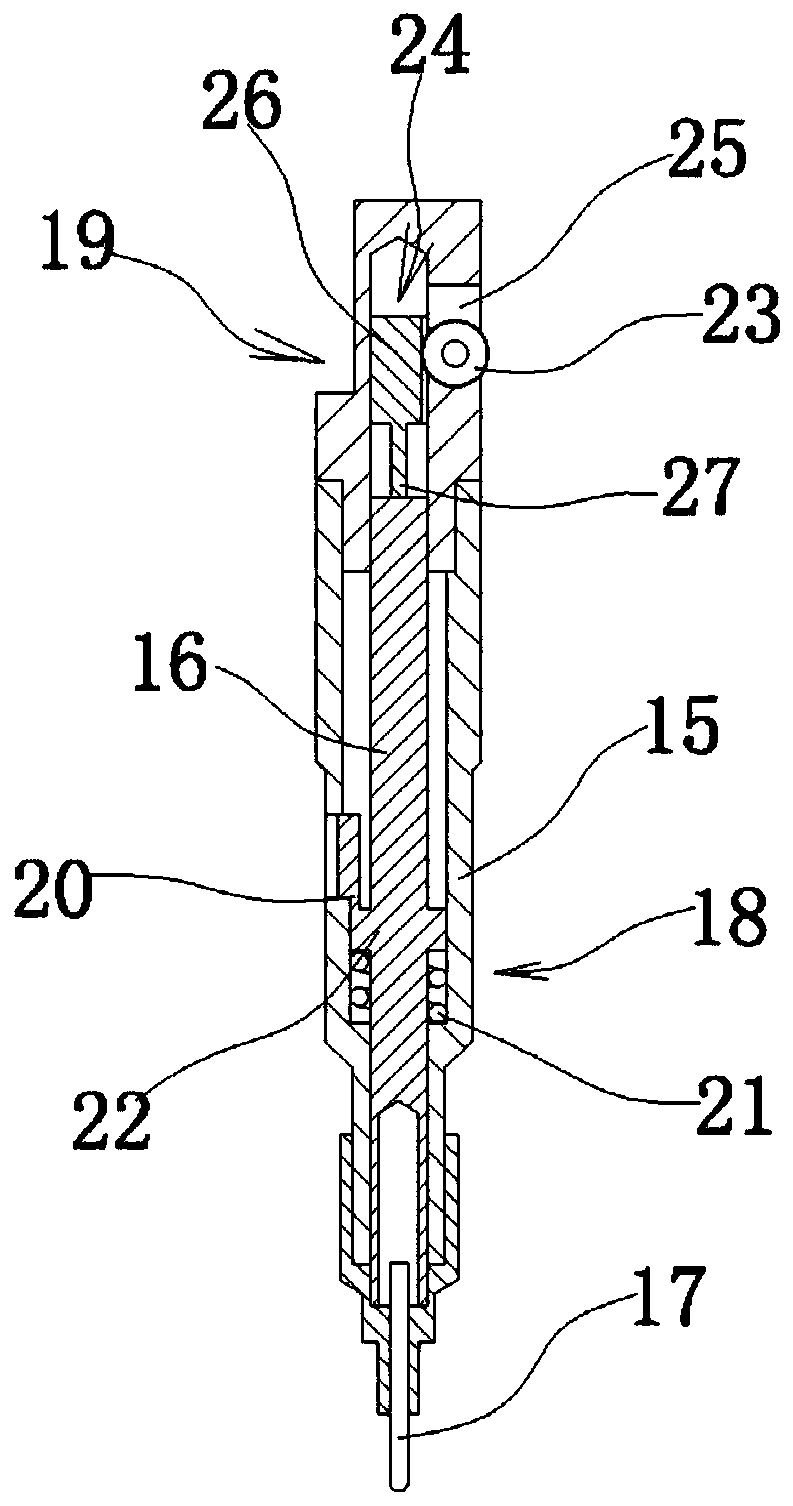

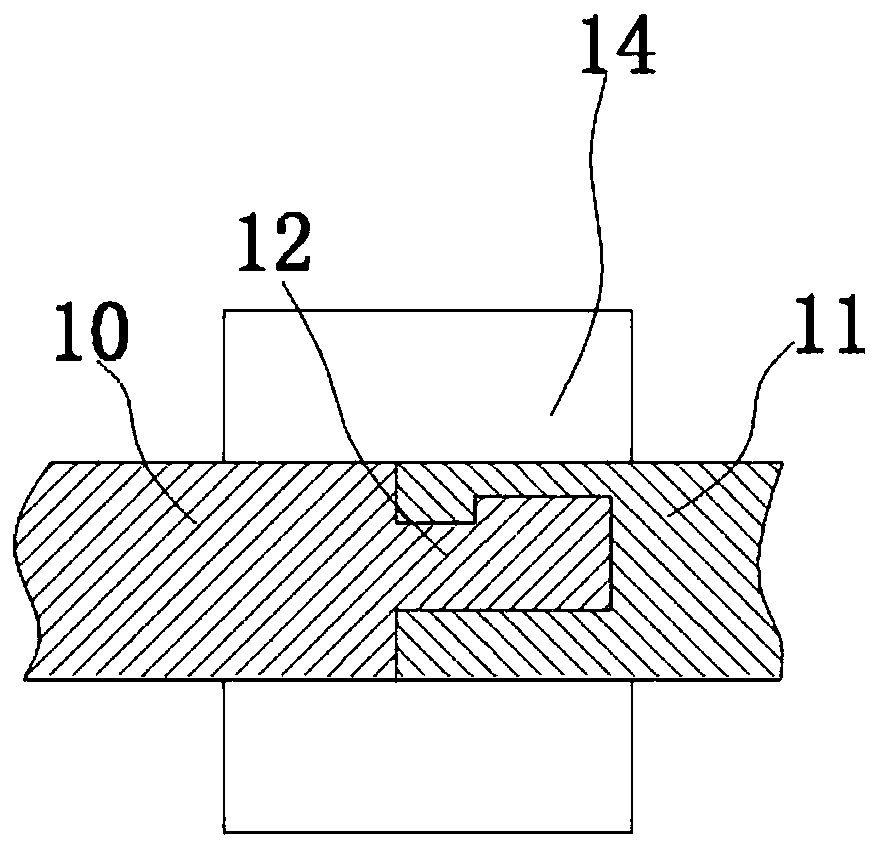

[0025] Such as figure 1 , figure 2 As shown, the needle shrinking structure of this knitting machine includes a frame 1, a moving mechanism 2 is arranged on the frame 1, and several groups of knitting needle members 3 that cooperate with each other are arranged on the moving mechanism 2. The left knitting needle 4 and the right knitting needle 5, the left knitting needle 4 and the right knitting needle 5 are connected on the same moving mechanism 2 and can carry out cooperative movement towards or away from each other, the outer surface of the left knitting needle 4 A first trigger block 6 protruding toward the right knitting needle part 5 and a second trigger block 7 opposite to the trigger block are arranged on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com