High-performance automobile support connecting piece

A technology of automobile brackets and connectors, which is applied in the direction of mechanical equipment, fixing devices, etc., can solve the problems that affect the overall performance of the automobile structure, the stability cannot meet the expected requirements, and the use cost and maintenance cost increase, so as to achieve the overall performance Reliable, tight and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

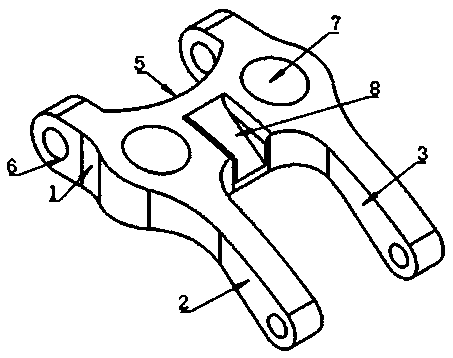

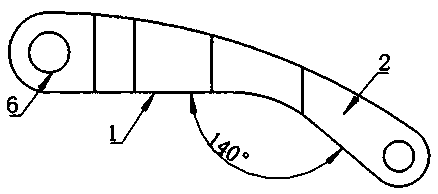

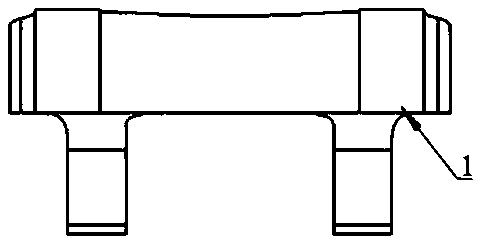

[0018] A high-performance automobile bracket connector, which adds a tightly reinforced connection circular arc groove on the basis of the original structure, which makes it more compact during assembly and can make the fatigue resistance of the parts stronger during use. Good, so that the service life of the part is longer, and the stability during use is more reliable. This part is calibrated by adding an assembly precision connection groove structure at the main body assembly position, so that it can be fastened at this position during assembly. Assembly can make the position accuracy of the parts better during assembly, so that it can meet the expected assembly accuracy after assembly, thus ensuring the stability of the connection during use and making the overall performance of the car more reliable. The security is higher, and the maintenance cost in the later use process is also reduced. It includes a main body assembly connection support plate 1, the lower end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com