Rotary tillage machinery running-in test bench

A test bench and mechanical technology, applied in the field of rotary tillage machinery, can solve the problems of insufficiency of use, too many electronic devices, increase production costs, etc., and achieve the effects of saving production costs, avoiding the use of sensors, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

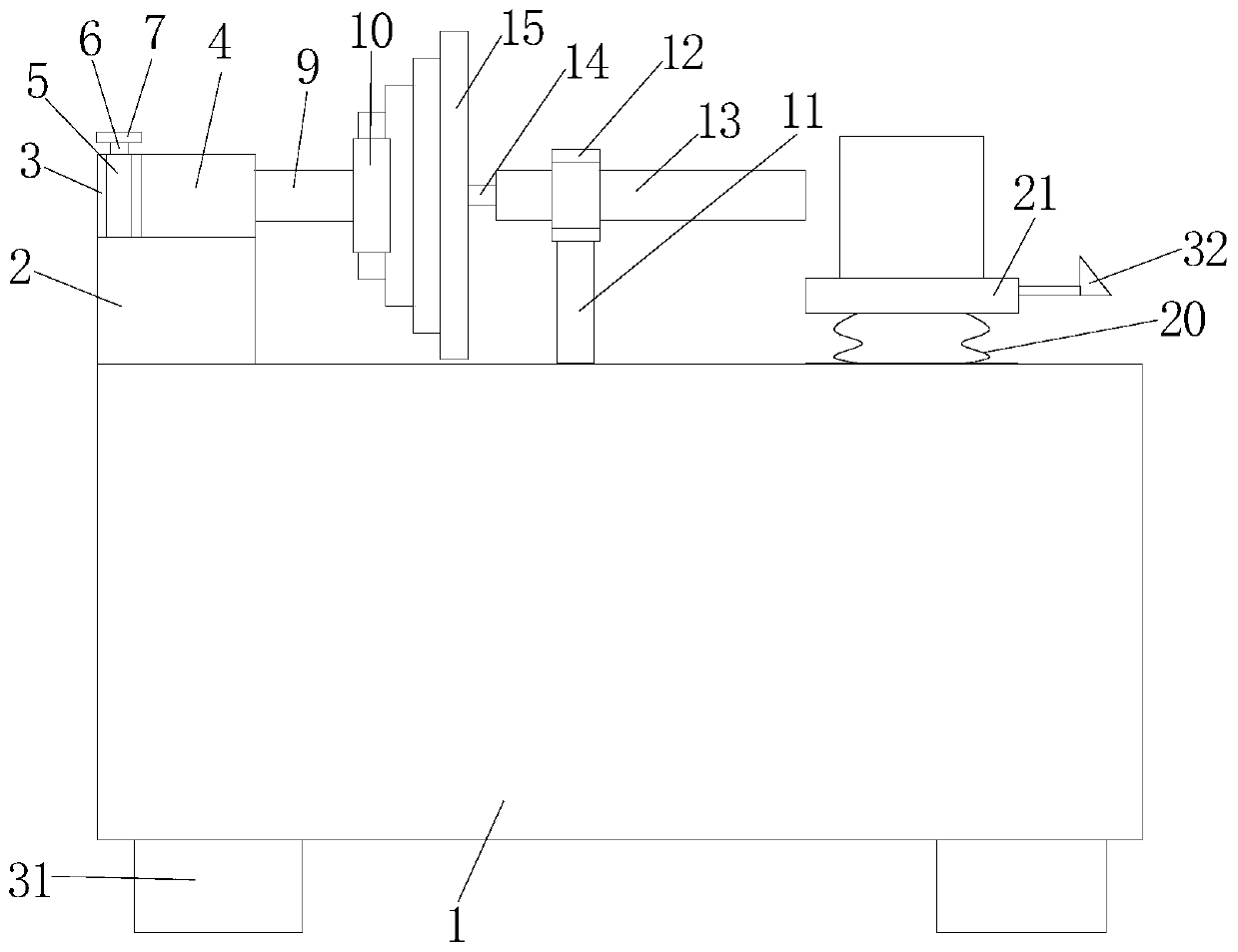

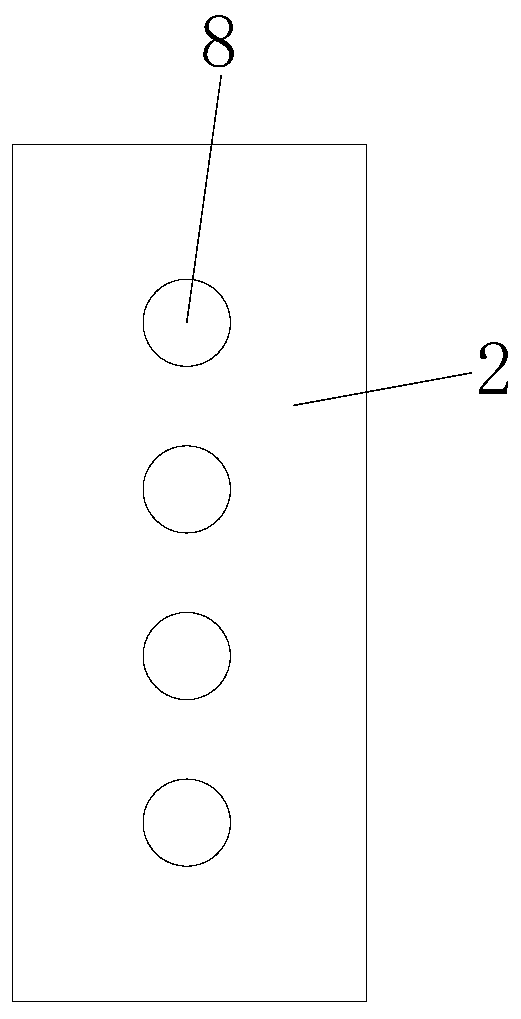

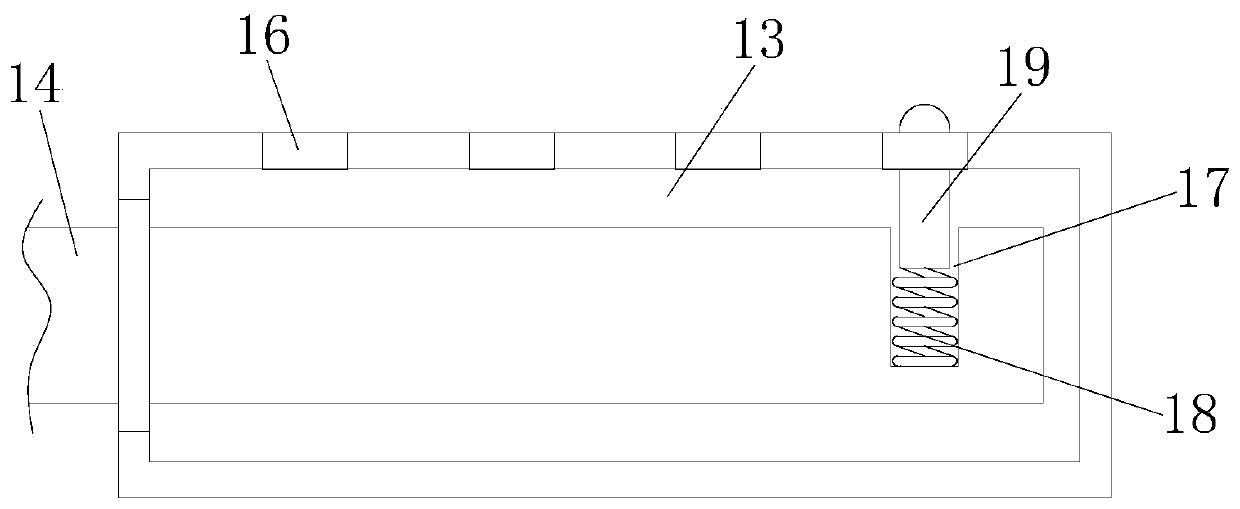

[0029] refer to Figure 1-6 , a running-in test bench for rotary tillage machinery, comprising a test bench body 1, a fixing seat 2 is provided on the top of the test bench body 1, and a mounting seat 3 is movable on the side of the fixing seat 2 away from the test bench body 1, and the mounting seat 3 One side is connected with a rotating motor 4, and a through groove 5 is opened on the mounting base 3, and a fully threaded stud 6 is arranged in the through groove 5, and the fully threaded stud 6 extends to the outside of the mounting base 3, and the fully threaded stud 6 is far away from the fixed One side of the seat 2 is provided with a turntable 7, and the side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap