Electrode strip laying device and method

A technology of electrode strips and positive electrodes, which is applied in the field of solar power generation panel manufacturing, can solve the problems of inability to guarantee product quality and low efficiency of solar power generation panels, and achieve the effect of ensuring product quality and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The word "embodiment" as used in this specification means an example, instance or illustration. Furthermore, as used in this specification and the appended claims, the article "a" or "an" may generally be construed as "one or more" unless specified otherwise or clear from the context in the singular.

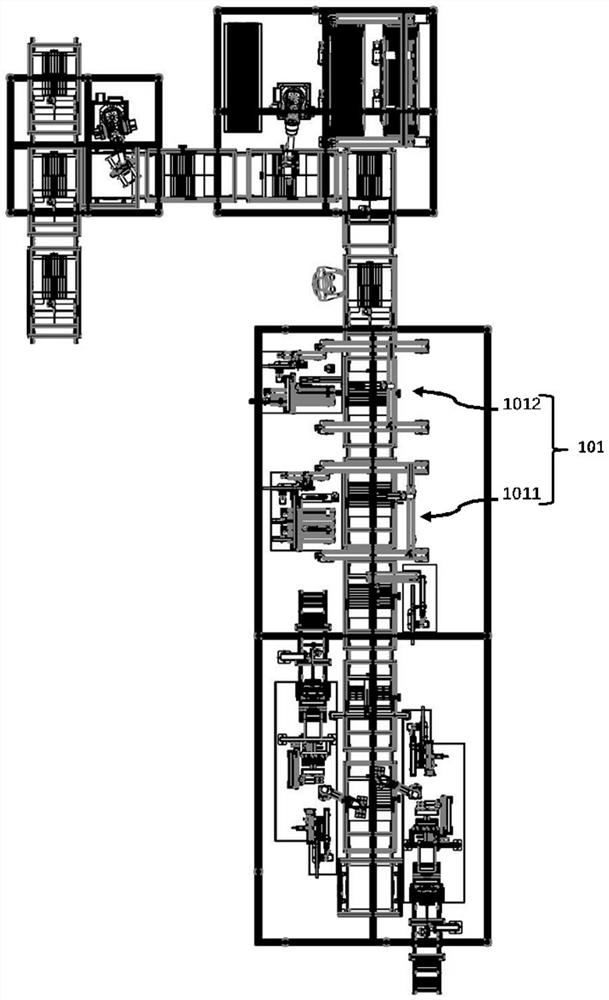

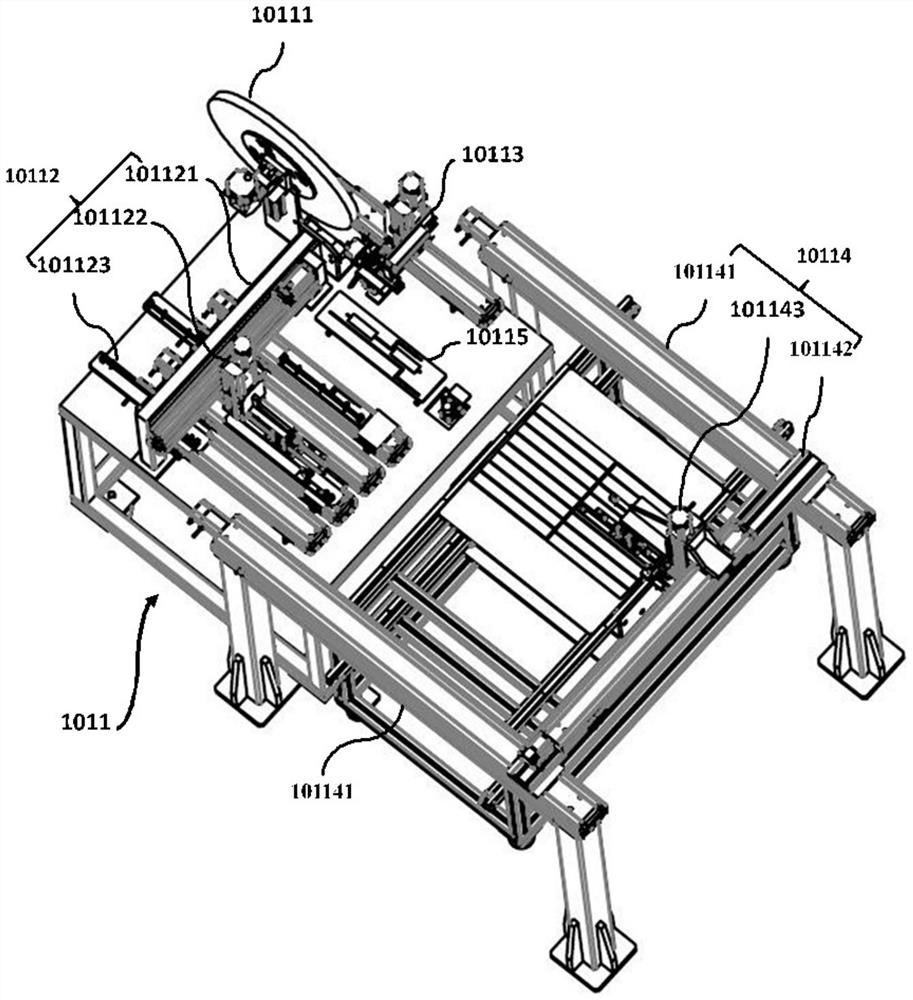

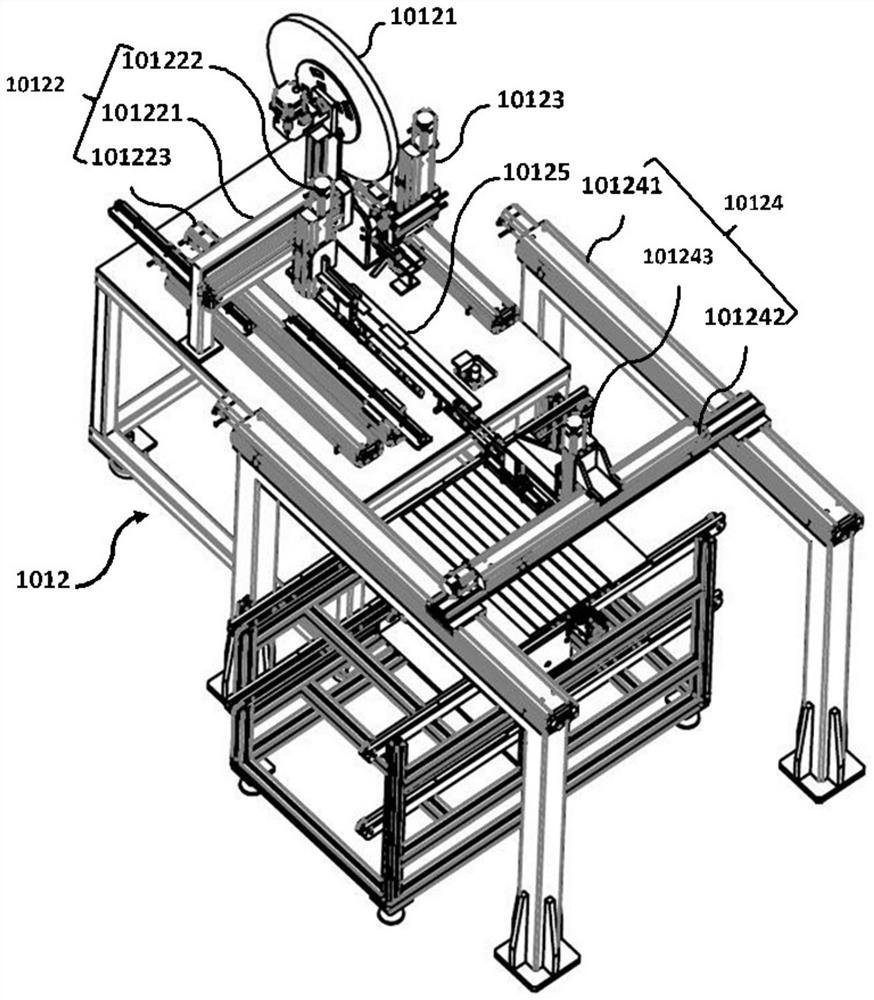

[0024] The electrode strip laying device 101 provided by the embodiment of the present invention is suitable for solar power generation panel manufacturing devices, such as figure 1 As shown, the solar power generation panel manufacturing device is used to manufacture solar power generation panels. Wherein, the solar power generation panel includes a plurality of power generation sheets, and the plurality of power generation sheets are arranged in a two-dimensional array to form a power generation sheet array. The generating sheet array includes two generating sheet combinations, the two generating sheet combinations are arranged side by side along the length direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com