Installing structure of assembled bathroom bottom plate

An installation structure and prefabricated technology, applied to water supply devices, drainage structures, building structures, etc., can solve problems such as obstruction of decoration work, bricks on the wall pressed against bricks on the ground, etc., to reduce gaps and improve waterproof performance , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

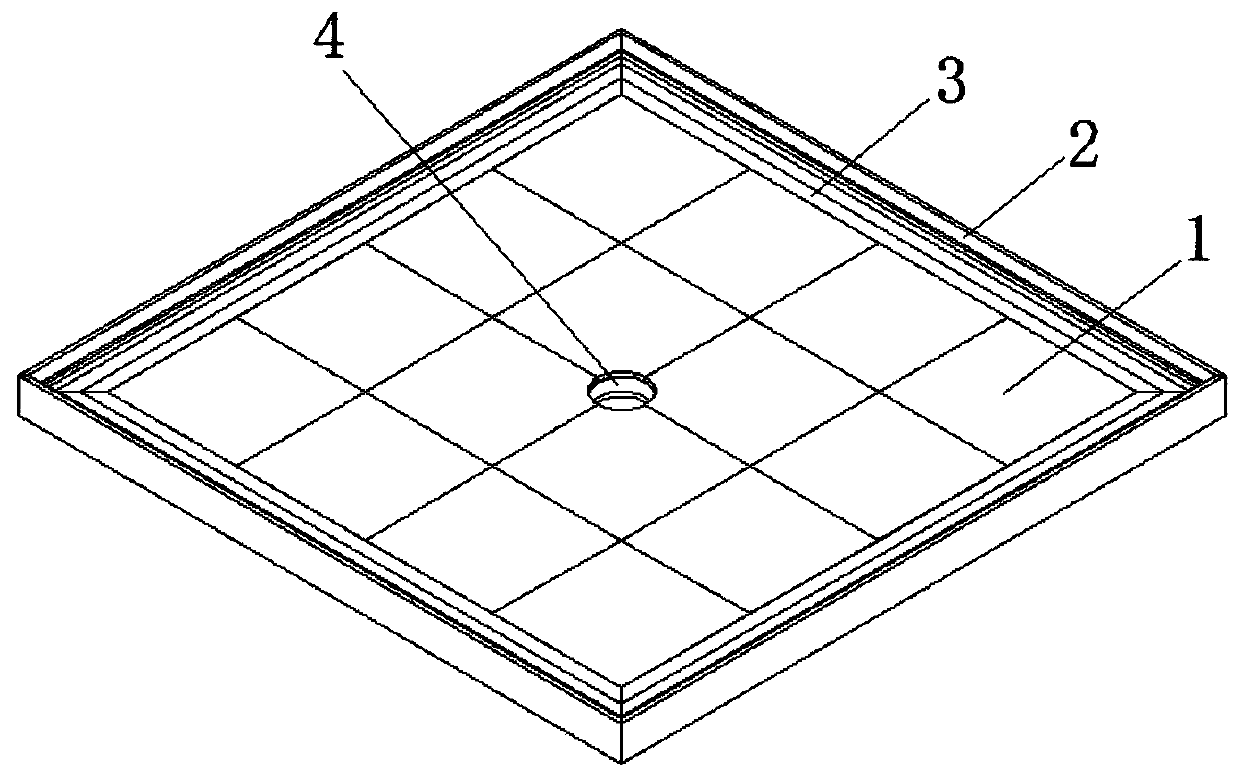

[0031] see Figure 1 to Figure 3 , the figure shows the installation structure of a prefabricated bathroom chassis provided by Embodiment 1 of the present invention, including: the base layer; 2. It includes an outer bar 21, a connecting bar 22 and an inner bar 23 arranged sequentially from the outside to the inside. A positioning groove 24 is arranged between the outer bar 21 and the connecting bar 22. The height of the outer bar 21 is higher than that of the connecting bar. 22. The height of the inner retaining bar 23; the outer frame 2 is square and is set around the tile 1; the leveling brick 3 is located between the tile 1 and the outer frame 2 and is laid along the horizontal direction; the floor drain 4 is set It is located in the middle of tile 1 and connected to the sewer.

[0032] The installation structure of a prefabricated bathroom chassis provided in this embodiment mainly includes the base layer, ceramic tile 1, outer frame 2, leveling brick 3 and floor drain o...

Embodiment 2

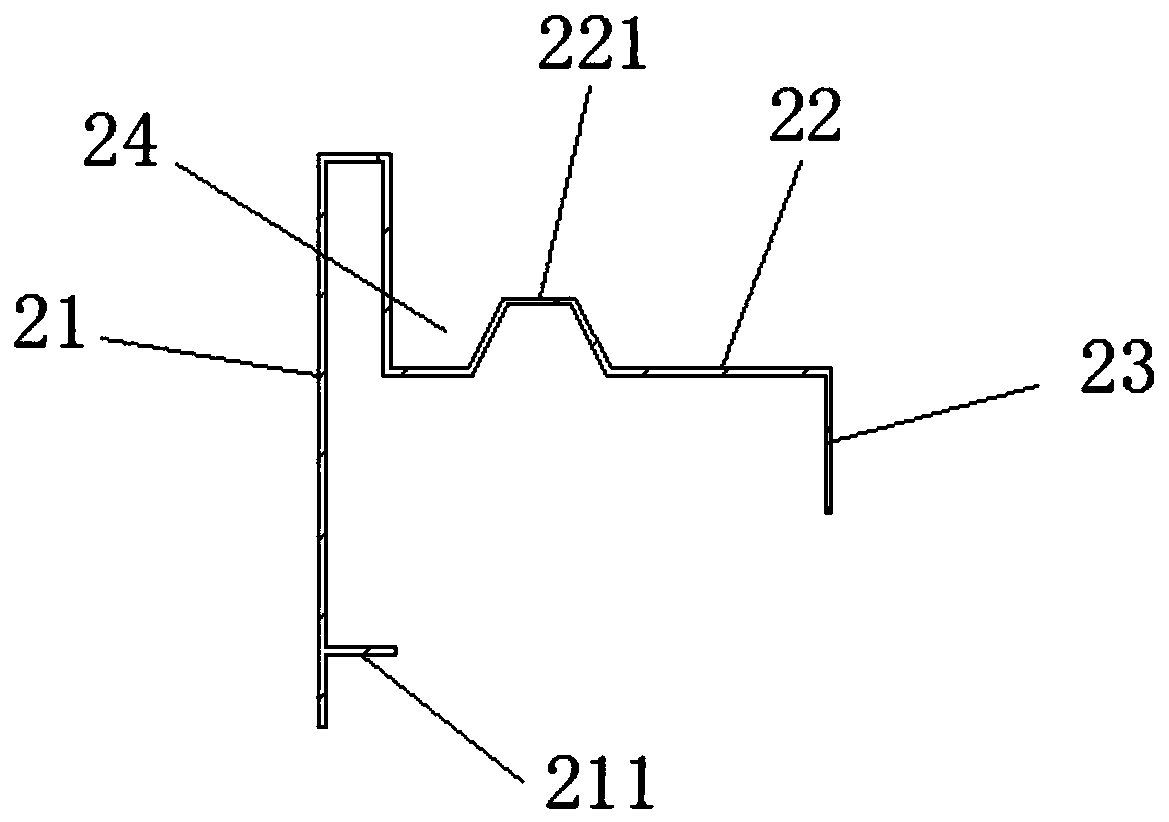

[0040] see Figure 1 to Figure 3 , the figure shows the installation structure of a prefabricated bathroom chassis provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the outer bar The top of 21 is a double-layer structure; the connecting bar 22 is provided with a reinforcing protrusion 221, and the reinforcing protrusion 221 is located inside the positioning groove 24; The inner side; the outer bar 21 and the clamping bar 211 are perpendicular. Through the setting of the above structure, the stability and rigidity of the outer rail 21 and the connecting strip 22 can be improved, and the positioning effect of the wall tiles can be improved; in addition, the setting of the clamping strip 211 can position the outer rail 21, which is convenient for installation .

Embodiment 3

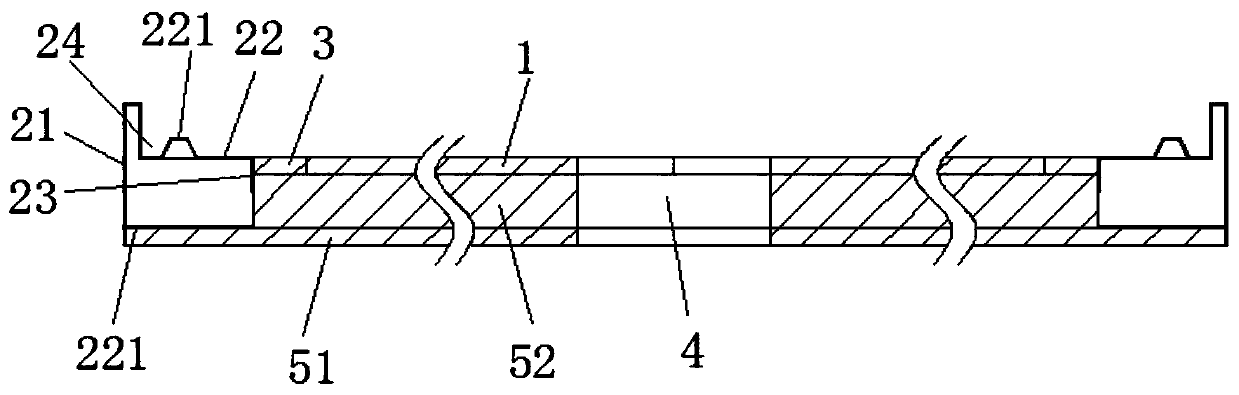

[0042] see figure 2 , the figure shows the installation structure of a prefabricated bathroom chassis provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the base layer consists of The first base layer 51 and the second base layer 52 from bottom to top, the tiles 1 and the leveling bricks 3 are all arranged on the second base layer 52; the external dimensions of the first base layer 51 are greater than the external dimensions of the second base layer 52; the outer bars 21 and The clamping strips 211 are respectively engaged with the side and top surface of the first base layer 51 ; the bottom of the inner retaining bar 23 is lower than the second base layer 52 , and the top thereof is flush with the leveling brick 3 . Through the setting of the above structure, the connection strength between the bottom of the outer bar 21 and the clamping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com