Double-stator staggered rotor tooth flux switching type permanent magnet motor and electromagnetic equipment

A technology of magnetic flux switching and permanent magnet motor, which is applied to magnetic circuits, electromechanical devices, electrical components, etc. Increase the difficulty of manufacturing and other issues to achieve the effects of high fault tolerance, improved winding coefficient, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

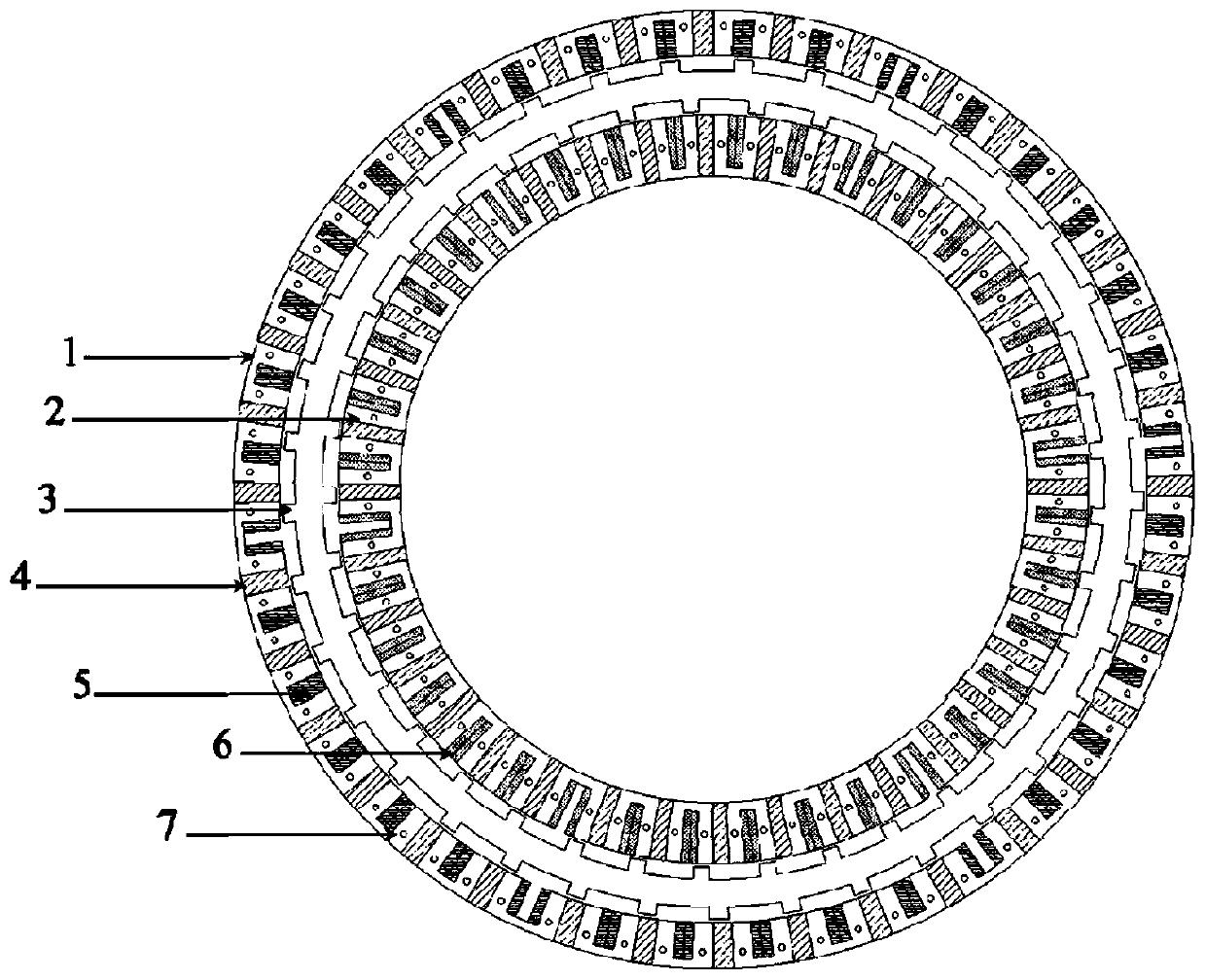

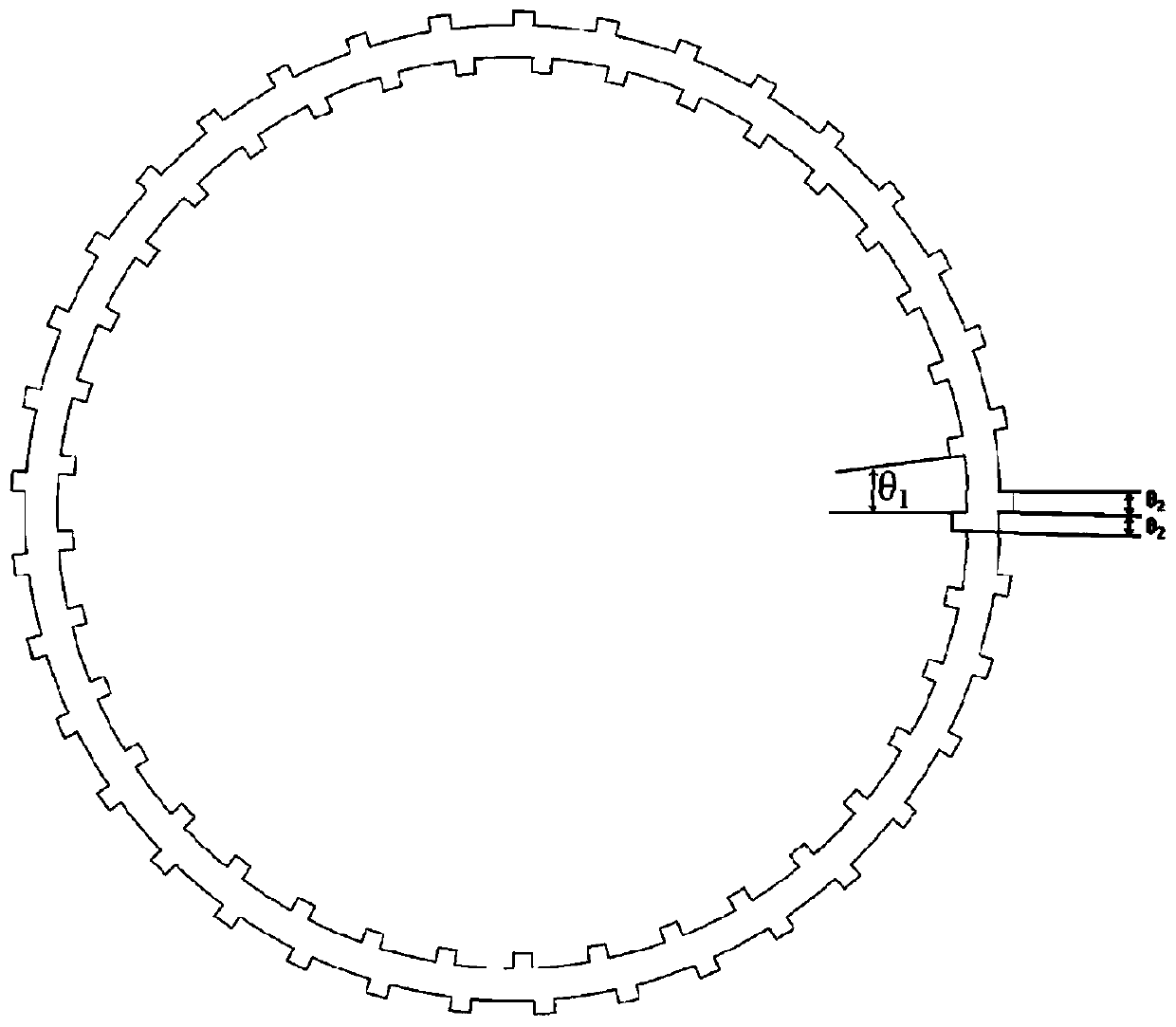

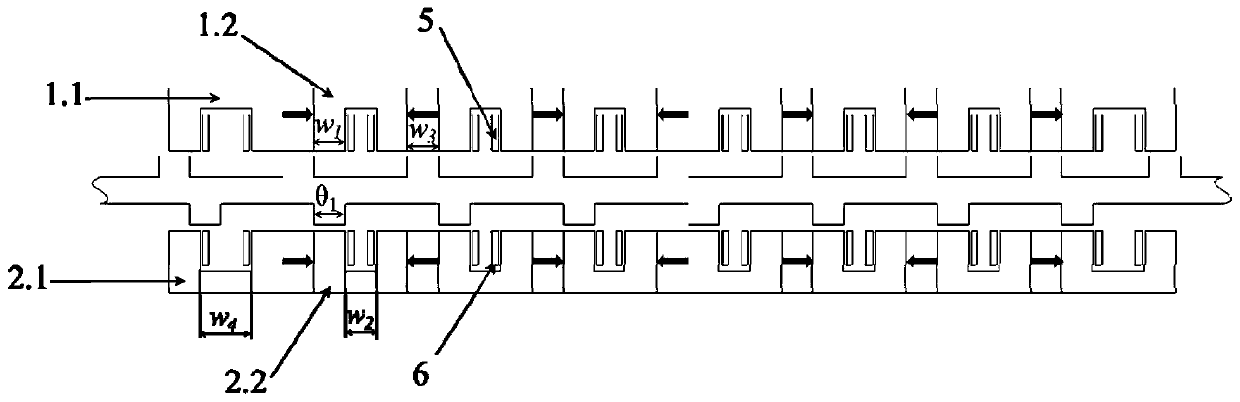

[0049] Such as figure 1 As shown, a flux-switching permanent magnet motor with double stators and rotor teeth in this embodiment includes an inner stator, an outer stator and a rotor.

[0050] Wherein, the inner stator is arranged inside the rotor 3; the inner stator includes the inner stator U-shaped core unit 2, the inner stator permanent magnet and the inner stator winding 6; the outer stator is arranged outside the rotor 3; the outer stator includes the outer stator U-shaped iron core unit 1, Outer stator permanent magnets 4 and outer stator windings 5 . Both the outer stator winding 5 and the inner stator winding 6 adopt multi-coil phase-group concentrated windings, which can be independently controlled; the inner stator permanent magnets are arranged between two adjacent inner stator U-shaped core units, and are closely attached to each other. installed; the stator permanent magnets are set between two adjacent stator U-shaped core units and are closely mounted. Both...

Embodiment 2

[0067] This embodiment provides the electromagnetic equipment as described in Embodiment 1, the electromagnetic equipment includes a double-stator dislocation rotor tooth flux switching permanent magnet motor, which adopts the dislocation arrangement structure of the inner rotor teeth and the outer rotor teeth to realize the permanent magnet flux The alternating polymerization on the inner and outer air gaps improves the torque density, and effectively suppresses torque ripple through the superposition of torque components generated by the double air gaps.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap