Industrial part size detection method based on machine vision

A size detection and machine vision technology, applied in instruments, measuring devices, image analysis, etc., can solve problems such as high operation difficulty, low part measurement efficiency, and expensive detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in combination with specific embodiments.

[0070] A kind of industrial part size detection method based on machine vision of the present invention, specifically implement according to the following steps:

[0071] Step 1, utilize image acquisition system to collect image; Wherein, image acquisition system comprises CCD industrial camera; CCD industrial camera, computer, single-chip microcomputer, relay are connected sequentially; Computer is also connected with infrared sensor;

[0072] The infrared sensor is an active infrared sensor;

[0073] The model of the one-chip computer is 89C51 one-chip computer.

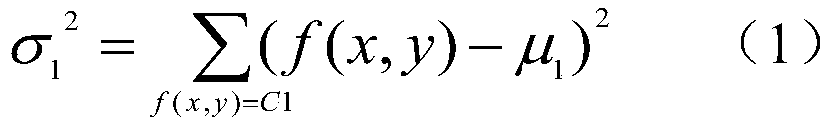

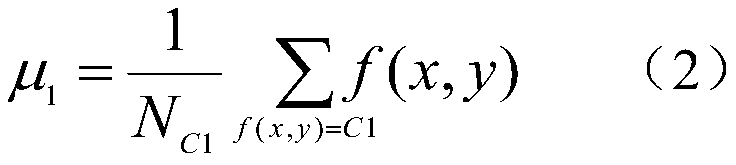

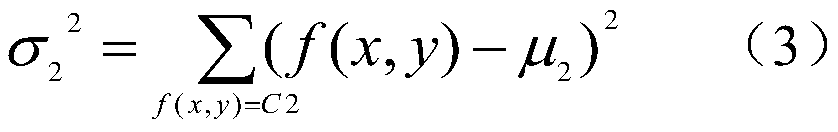

[0074] Step 2. Perform median filtering, threshold segmentation, image filling, Canny edge rough extraction, edge fine extraction, and size calibration on the image in order to obtain size data;

[0075] The specific process of median filtering is as follows:

[0076] Using a 3×3 two-dimensional sliding tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com