Slicer cutting area wire net center adjusting device and adjusting method

A technology of wire mesh center and cutting area, which is applied in the direction of fine working devices, working accessories, manufacturing tools, etc., can solve the problems that the rotation center distance cannot be adjusted, affects the cutting yield, and limits the cutting capacity of the slicer, etc., to achieve improved cutting effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

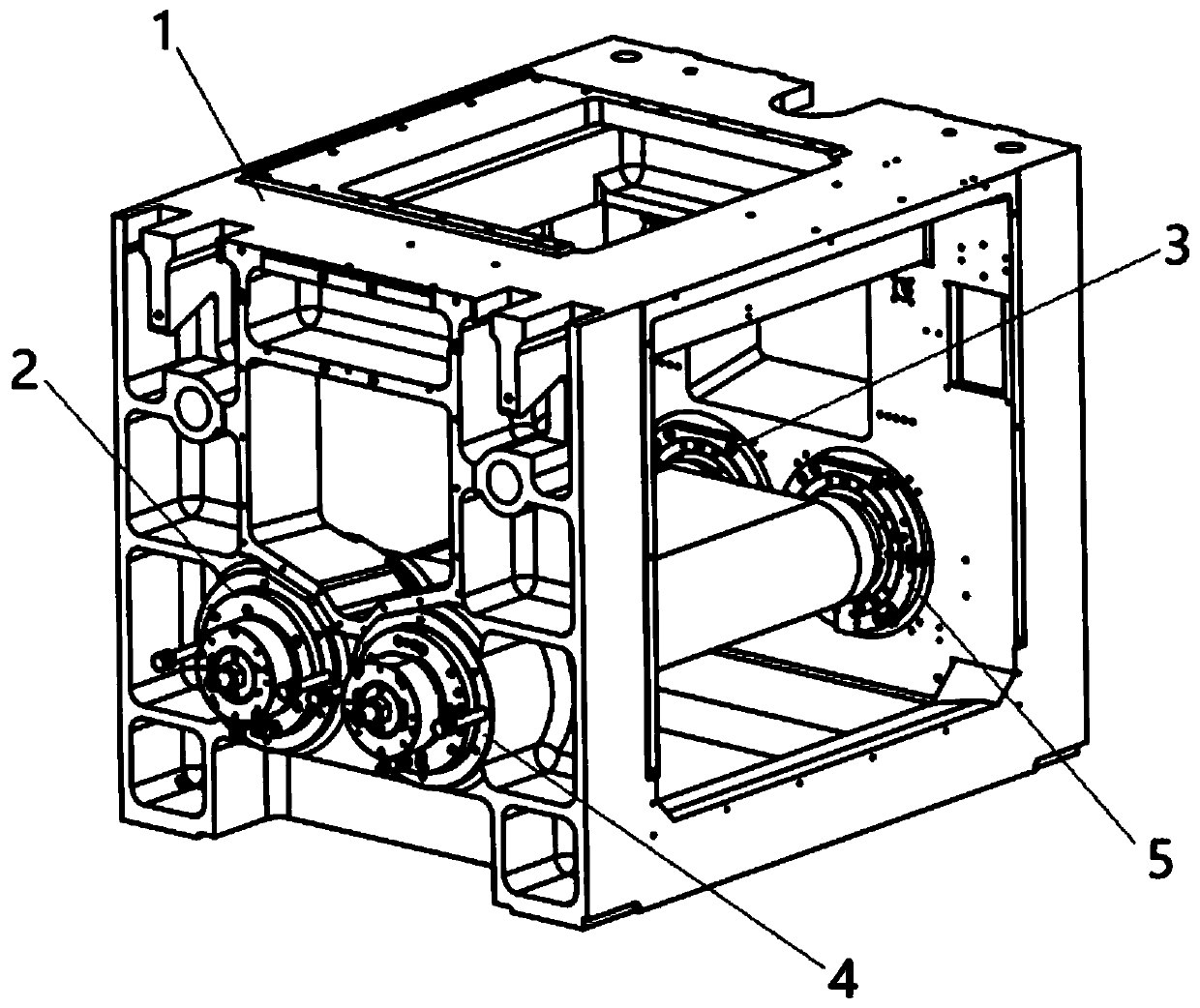

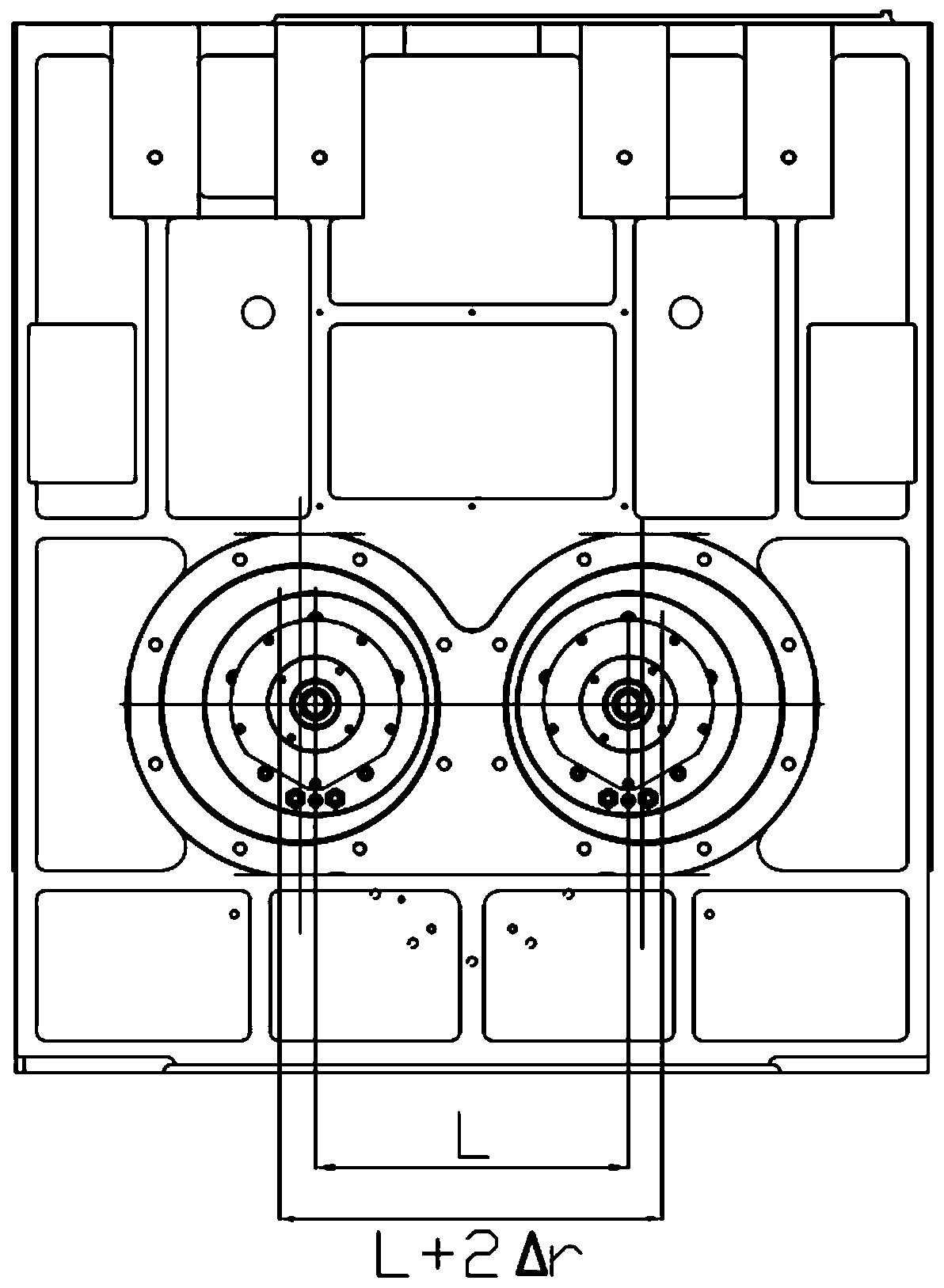

[0027] see figure 1 , figure 2 , the present invention adjusts the device of slicer cutting area line net center, and this device is arranged at the cutting area of slicer, comprises frame 1, and frame 1 front side offers first front inner hole and second front inner hole, meanwhile, frame 1 The rear side is provided with a first rear inner hole and a second rear inner hole.

[0028] In this embodiment, the centers of the first front inner hole and the first rear inner hole are optimally on the same axis, and similarly, the centers of the second front inner hole and the second rear inner hole are optimally on the same axis.

[0029] A first eccentric support roller is arranged between the first front inner hole and the first rear inner hole, and a second eccentric support roller is arranged between the second front inner hole and the second rear inner hole. The first eccentric support roller is composed of a first eccentric sleeve assembly, a first bearing box assembly an...

Embodiment 2

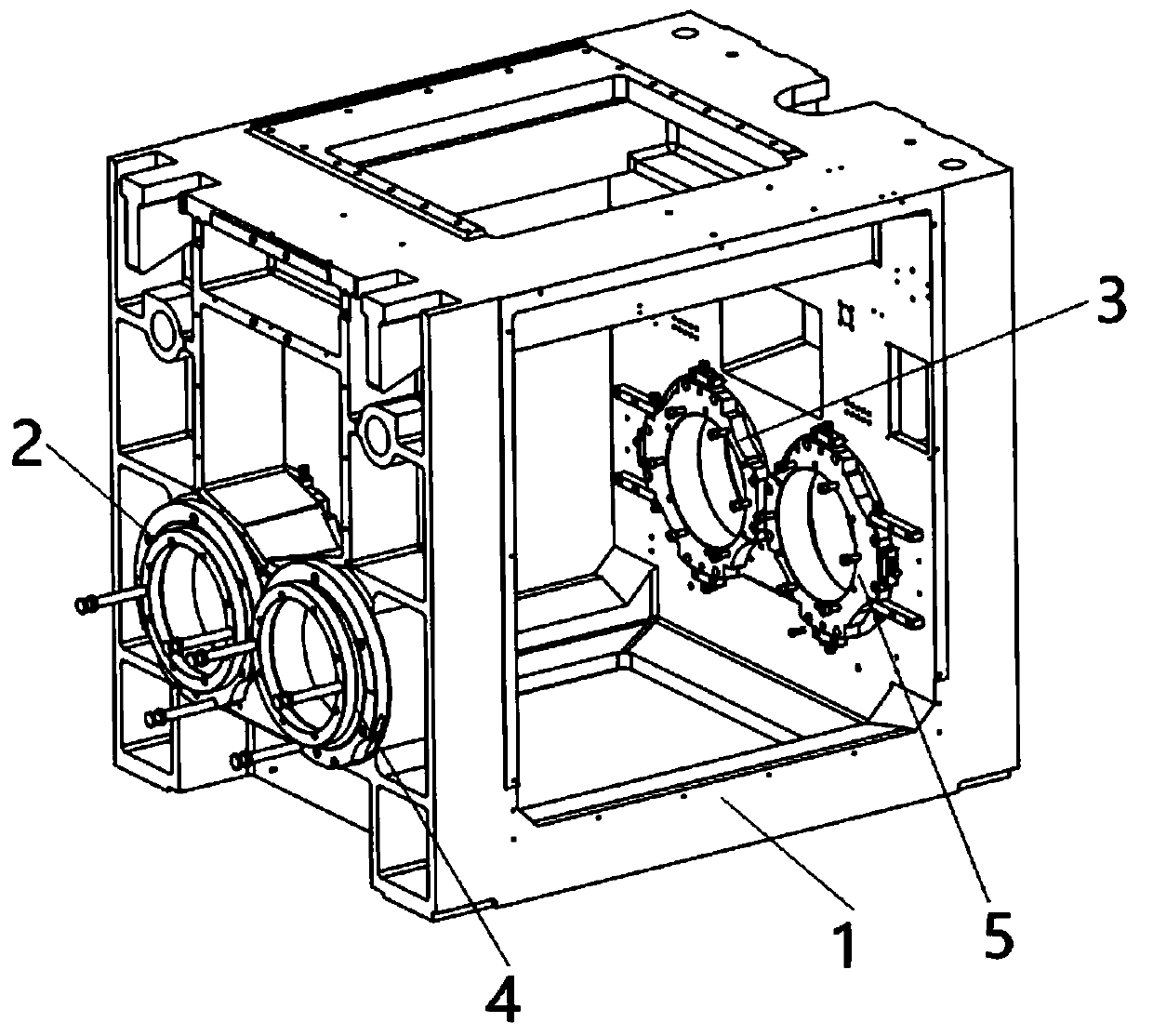

[0035] see Figure 4 , Another embodiment of the device for adjusting the wire mesh center in the cutting area of the slicer according to the present invention is different from Embodiment 1 in that the first eccentric support roller is composed of the first eccentric bearing box assembly and the first main roller. The second eccentric support roll is composed of the second eccentric bearing box assembly and the second main roll.

[0036] The first eccentric bearing box assembly includes the first front eccentric bearing box 6 and the first rear eccentric bearing box 7, the first front eccentric bearing box 6 is fixed in the first front inner hole, and the first rear eccentric bearing box 7 is fixed in the first In the posterior inner hole. The first main roller is arranged between the first front eccentric bearing box 6 and the first rear eccentric bearing box 7 .

[0037] The second eccentric bearing box assembly includes a second front eccentric bearing box 8 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com