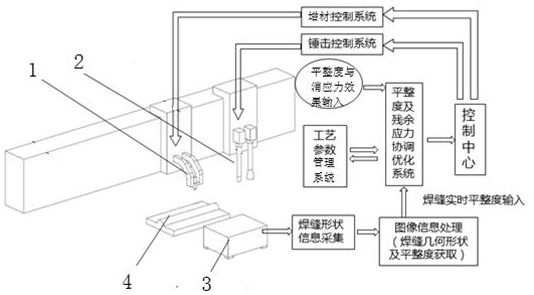

Self-feedback control method and system for coordinated optimization of lumber flatness and residual stress

A residual stress, coordination and optimization technology, applied in the field of additive manufacturing, can solve the problems of non-compliance of welds and the quality of additive products, and achieve the effect of avoiding non-compliance with requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In the prior art, it is desirable to obtain a smaller initial flatness when adding materials. The present invention works in the opposite way, adopting a larger initial flatness to ensure that the welding seam produces sufficient plastic extension deformation after the contact impact to offset the uncoordinated strain. Therefore, the greater flatness after the addition of materials will greatly help the subsequent hammering work. At the same time, the flatness after hammering is considered to ensure that the shape and flatness of the weld after the contact impact must also meet the standard.

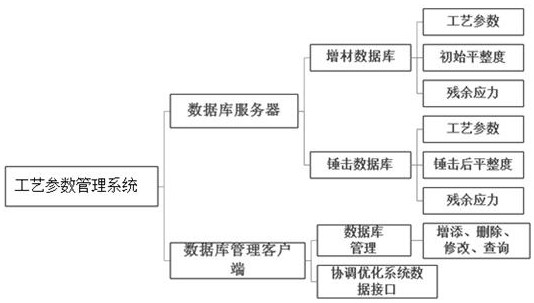

[0037]A self-feedback control method for coordinating and optimizing the flatness of accumulated lumber and residual stress includes the following steps:

[0038]According to the historical data of additive process and hammering process, the following corresponding relationship is established:

[0039]The relationship between the flatness of the weld and the residual stress is used to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com