A rail corrugation detection device

A detection device and corrugation technology, which is applied in the direction of measuring devices and instruments, can solve the problems of incomplete judgment of track status, small detection range, and track damage, and achieve the effect of complete judgment, large detection range, and avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

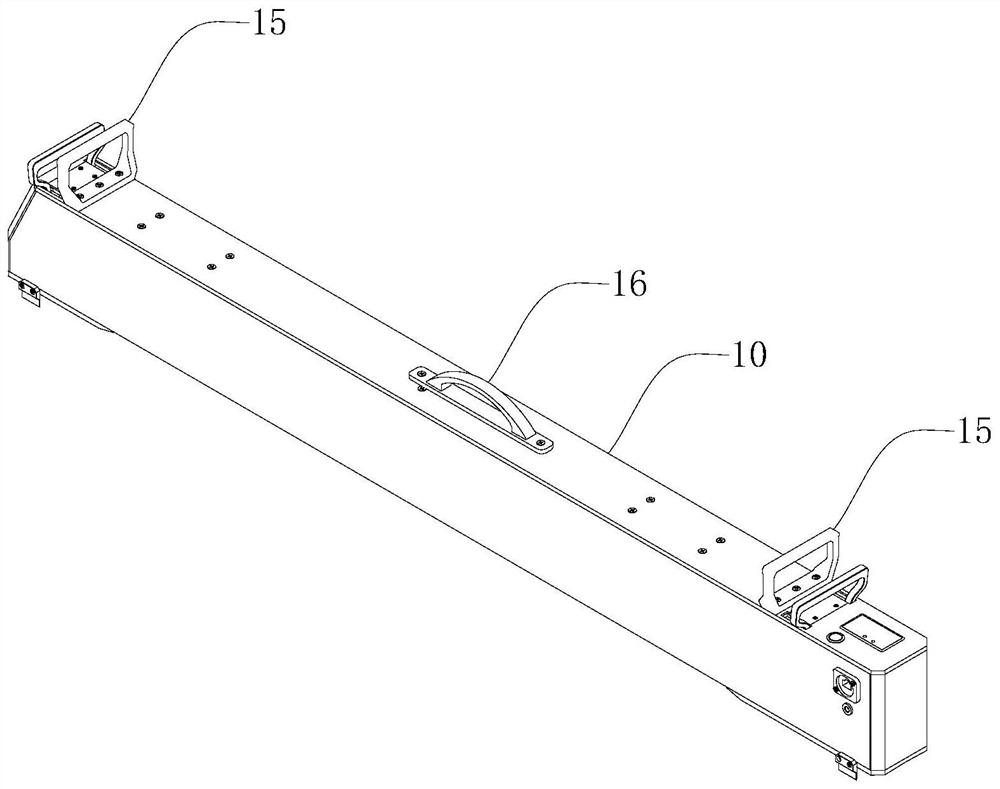

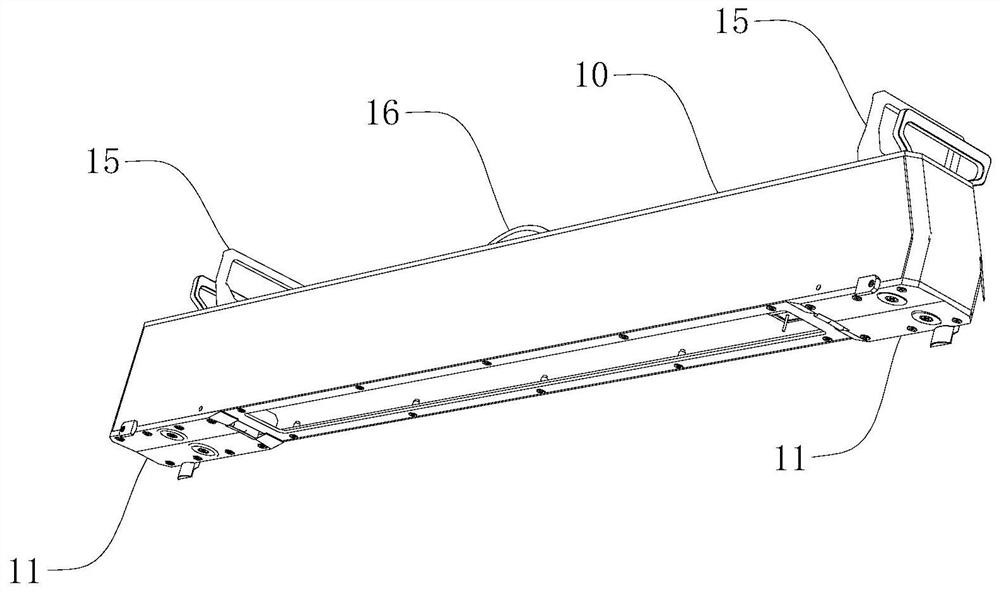

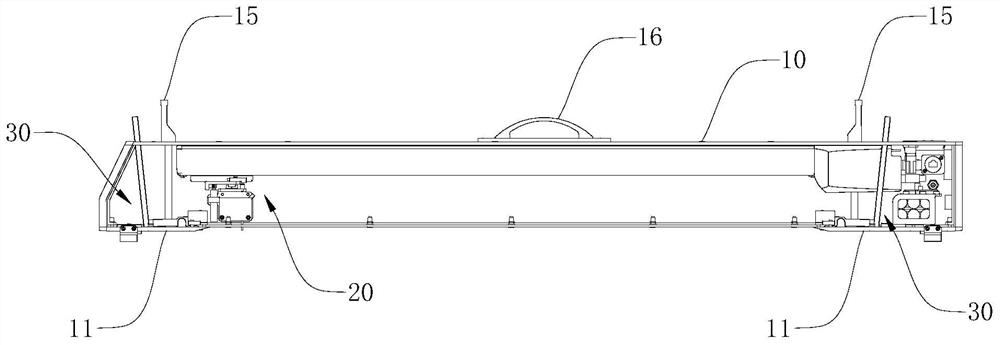

[0035] Please refer to FIG. 1 and FIG. 2, a rail corrugation detection device, comprising: a box 10 in the shape of a long strip. Top of box 10

[0037] Please refer to FIG. 4 , the detection assembly 20 includes a servo electric cylinder 21 , a connection block 22 and a 1D sensor 23 . Servo Electric Cylinder 21

[0041] Please refer to FIG. 5, the first adsorption block 12 at the bottom of the base 11 is used for adsorption with the track 40 to realize the locking of the device. base

[0042] The unlocking assembly 30 includes a handle 31 and a link 32. One end of the handle 31 is located inside the box body 10, and the other end protrudes

[0044] In this embodiment, the first adsorption block 12 and the second adsorption block are both magnets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com