In-situ loading device and method for fiber drawing test of fiber concrete

A pull-out test and in-situ addition technology, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve the problem that the mechanical properties of the interface between the fiber and the matrix cannot be realized, and the complex three-dimensional interface between the fiber and the matrix cannot be realized. space, the inability to obtain the deformation of the fiber matrix interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

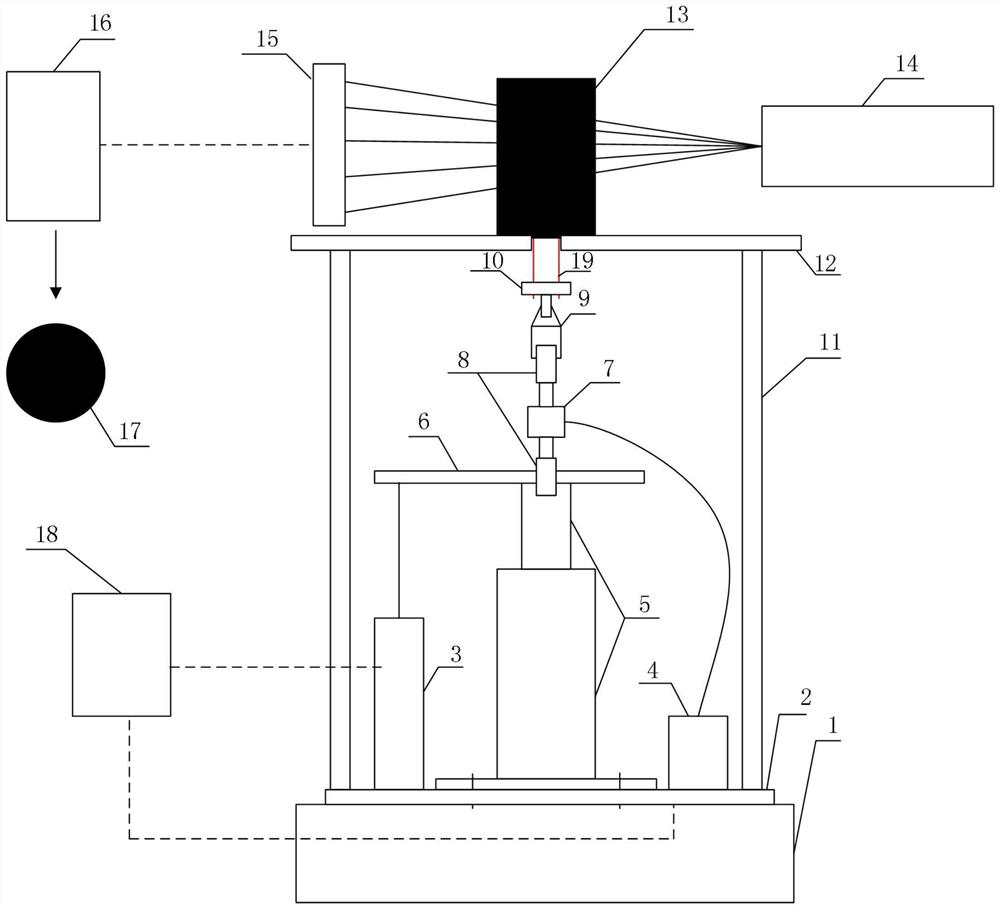

[0018]byfigure 1It can be seen that the in-situ loading device for the fiber pull test includes a rotating platform (1), a support base (2), a displacement meter (3), a transmitter (4), an electric tension (compression) rod (5), and a thin steel plate ( 6) Tension (compression) force sensor (7), connecting piece (8), chuck (9), fastening conversion piece (10), steel column (11), supporting top plate (12), X-ray source (14) ), detector (15), image acquisition device (16), data acquisition device (18);

[0019]The load platform is connected with the electric tension (compression) rod, the electric tension (compression) rod is connected with the tension (compression) force sensor through the connector, and the tension (compression) force sensor is connected with the chuck through the connector, and the chuck and tightening are switched Connecting parts, fasten the conversion part and fiber connection, the thin steel plate is connected with the electric tension (compression) rod, the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com