Fast recovery diode device structure and manufacturing method thereof

A technology for recovering diode and device structures, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve process compatibility and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

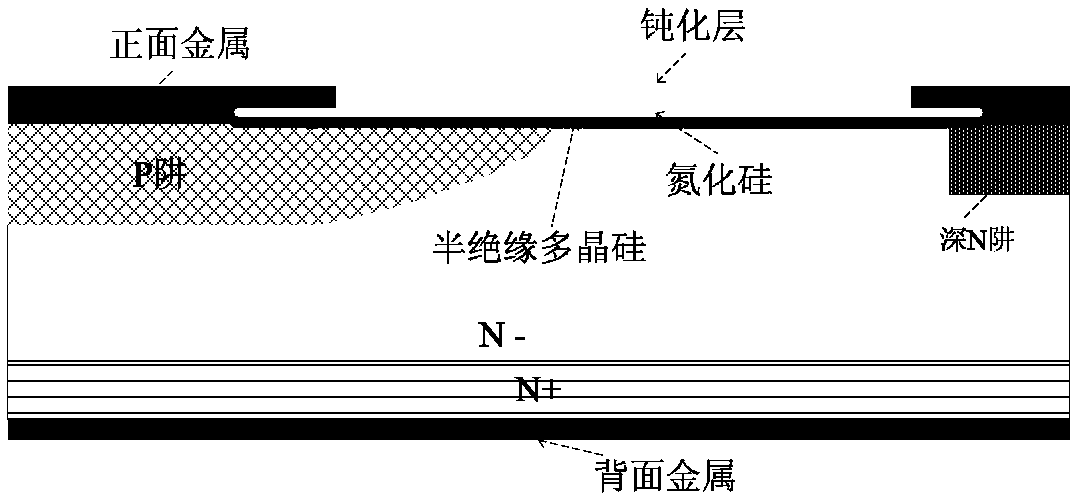

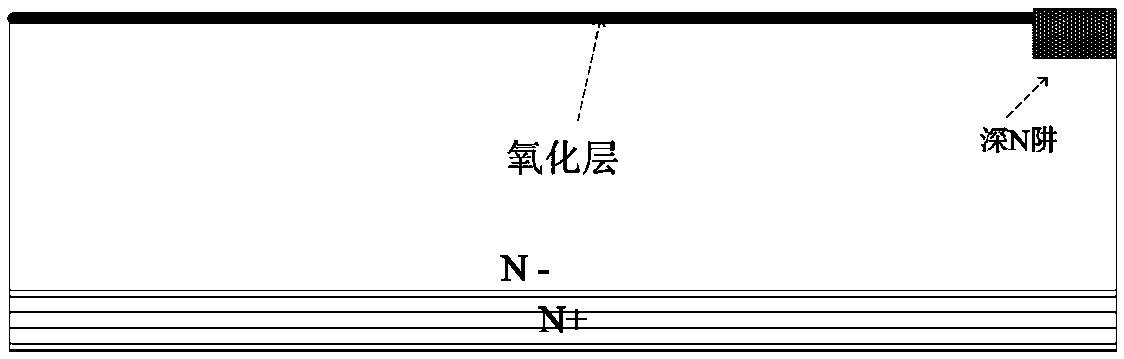

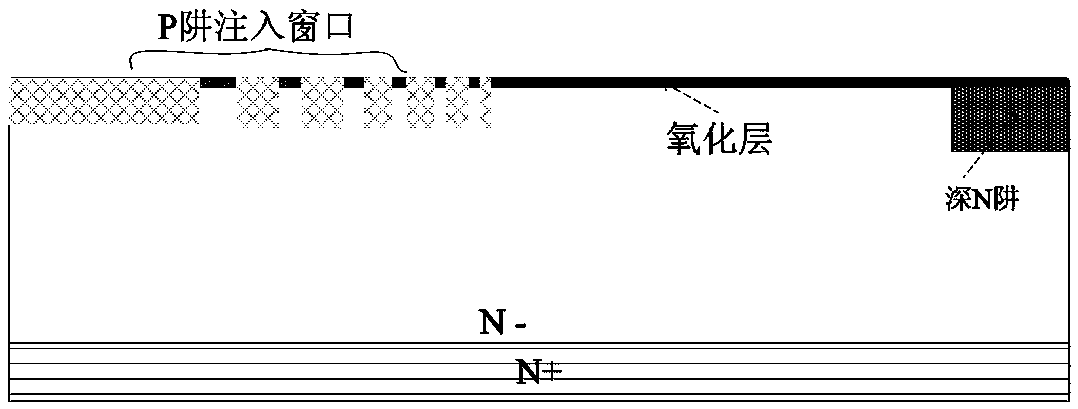

[0025] Such as Figure 1-5 As shown, a fast recovery diode device structure according to the present invention mainly includes an N-type epitaxial substrate, and the N-type epitaxial substrate includes an N+ substrate layer and an N- epitaxial layer arranged on the N+ substrate layer, A semi-insulating polysilicon layer and a silicon oxide layer are sequentially arranged in the middle of the top of the N-epitaxial layer, and a front metal layer is arranged on the left and right sides of the top of the N-epitaxial layer, and the height of the front metal layer is higher than that of the semi-insulating layer. The height of the polysilicon layer and the silicon oxide layer, the top of the silicon oxide layer and one s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap